Ное . 19, 2024 15:02 Back to list

chicken meat filleting machine factories

The Rise of Chicken Meat Filleting Machine Factories

In the modern food processing industry, efficiency and precision are paramount, particularly in the handling of poultry products. As consumers increasingly demand high-quality chicken meat, the role of chicken meat filleting machine factories has become more significant. These specialized facilities utilize advanced technology to enhance production processes, ensuring that the meat is not only processed quickly but also meets stringent quality standards.

Chicken filleting involves the delicate task of removing bones and excess fat from chicken, creating products that are ready for cooking or further processing. Traditional methods of filleting often require skilled labor, which can be both time-consuming and inconsistent. The emergence of chicken meat filleting machines has revolutionized this process by automating labor-intensive tasks, reducing the reliance on manual labor, and increasing overall productivity.

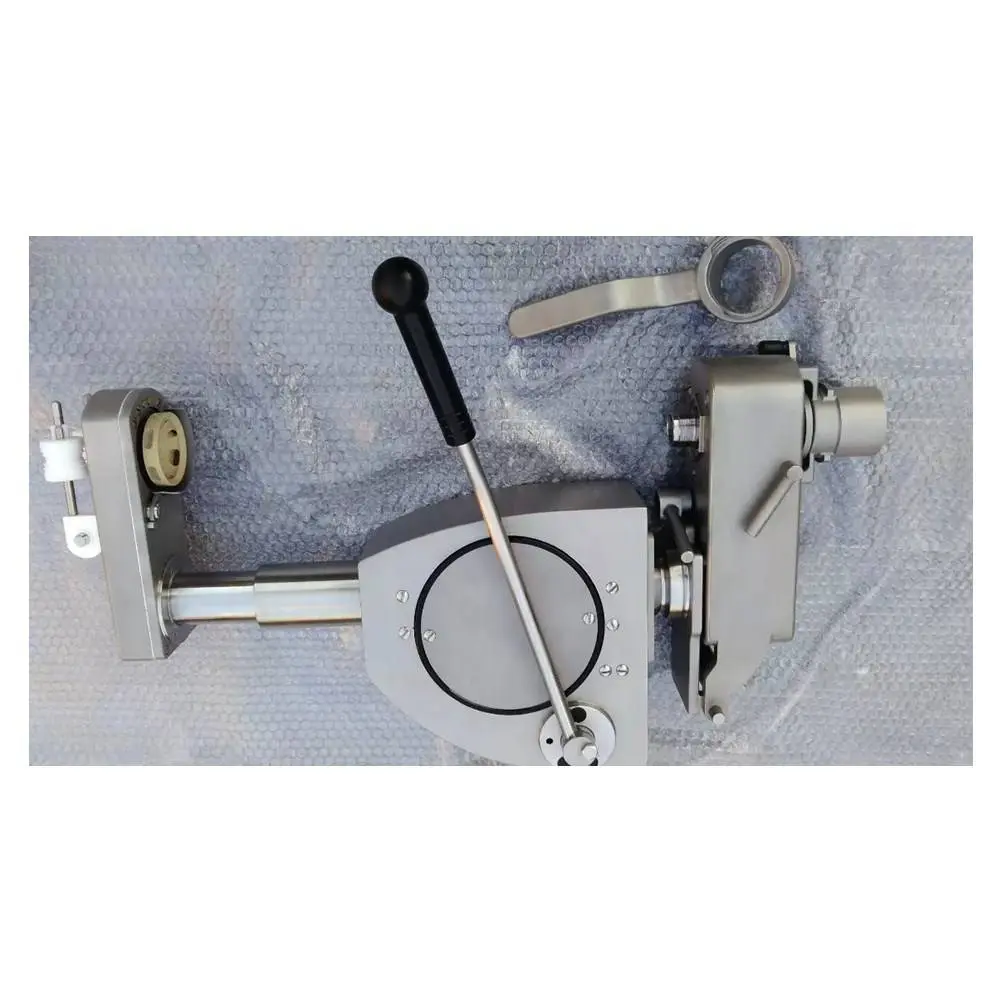

The machinery used in these factories is designed with precision engineering, allowing for uniform cutting and minimal waste. Modern filleting machines can process hundreds of chickens per hour, ensuring that manufacturers can meet rising consumer demands without sacrificing quality. With features like adjustable cutting blades and digital automation, these machines provide a level of accuracy that manual filleting cannot achieve. This accuracy not only improves yield but also enhances the overall safety of the food products being prepared.

One of the most notable advantages of chicken meat filleting machine factories is their ability to ensure food safety. With regulations around food processing becoming more stringent worldwide, these factories are equipped with technology that minimizes the risk of contamination. Automated systems can operate in controlled environments, reducing human interaction, which is a key factor in maintaining hygiene standards. Additionally, many machines are designed with easy-to-clean features, allowing for efficient sanitation processes that comply with health regulations.

chicken meat filleting machine factories

Environmentally, the rise of these factories has the potential to contribute positively. By maximizing efficiency and reducing waste, chicken filleting machine factories can help lower the carbon footprint of chicken production. Reduced manual labor also translates to less energy consumption and lower water usage during processing. Moreover, with increased yields due to precision filleting, more meat can be generated from a single chicken, effectively serving a growing population while minimizing the impacts on animal husbandry.

These factories are not without challenges. Initial investments in high-tech machinery can be daunting for small and medium enterprises. Furthermore, as automation becomes more prevalent, there is a growing concern about job displacement for workers traditionally employed in manual filleting roles. However, rather than simply replacing human labor, these machines often shift the focus of workers toward operating and maintaining the technology, illustrating a transition in required skills in the industry.

As the poultry market continues to evolve, the demand for high-quality, efficiently produced chicken meat will likely grow. Chicken meat filleting machine factories represent a significant advancement in meeting these needs. By combining technology with traditional practices, these factories can improve production efficiency while ensuring the safety and quality of meat products.

In conclusion, the rise of chicken meat filleting machine factories marks a pivotal development in the food processing landscape. Through automation, they enhance production processes, maintain stringent quality and hygiene standards, and promote sustainability in poultry processing. As technology continues to advance, one can only anticipate further innovations that will shape the future of the poultry industry, making it more efficient and responsive to consumer demands. The challenge will be to ensure that this transformation benefits both producers and consumers alike, weaving a future where quality, efficiency, and sustainability coalesce harmoniously in the chicken meat market.