ജനു . 14, 2025 11:53 Back to list

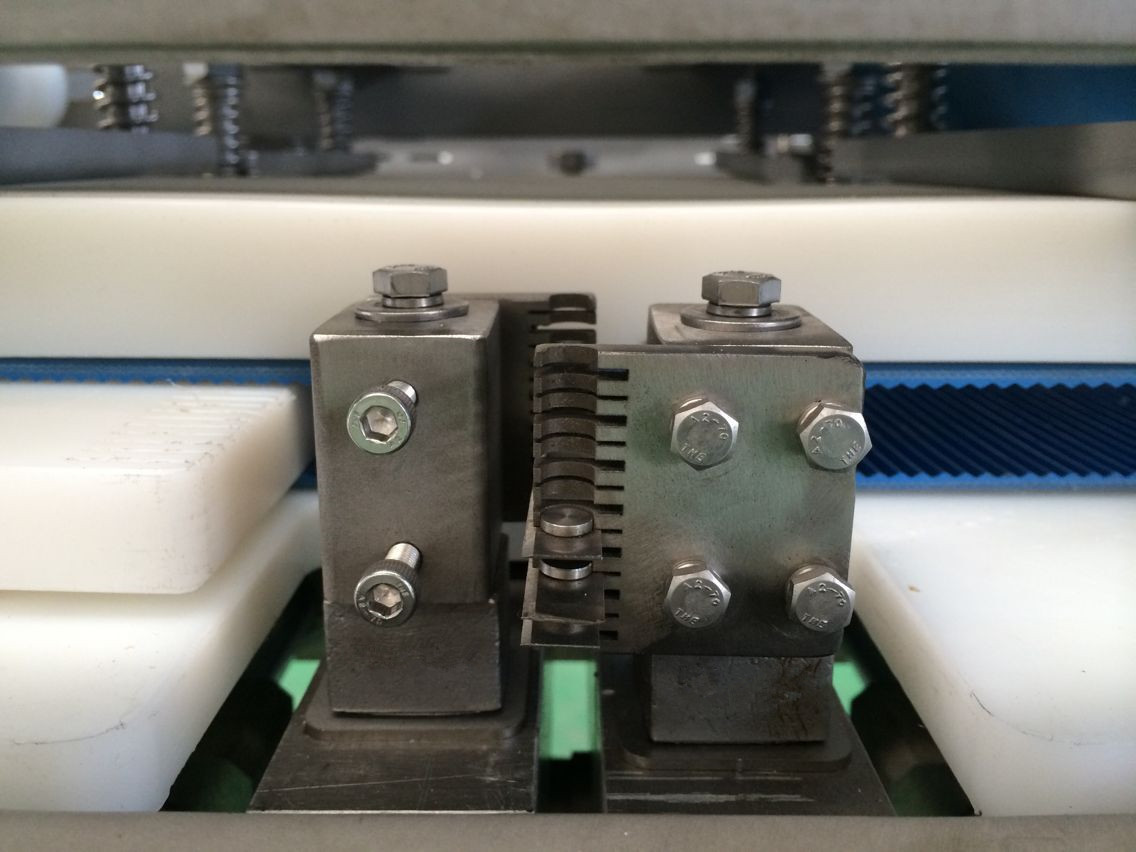

Bearing

The landscape of modern meat processing has seen rapid transformations with the advent of automation technologies. In this dynamic environment, the sausage automatic clipper has emerged as a revolutionary tool for sausage manufacturers, streamlining operations and enhancing output quality.

Authoritative reports in the field suggest a rise in demand for automated solutions as consumers become increasingly health-conscious and demand transparency in food production processes. Consequently, the ability of the automatic sausage clipper to deliver consistent and hygienic results strengthens a brand’s reputation in demonstrating product reliability and consumer safety. Trustworthiness is underscored by the machine’s ability to consistently output top-quality products. Investment in such technology conveys a commitment to excellence and adherence to industry standards, fostering consumer confidence. These machines are often subject to stringent international norms for food safety and hygiene; thus, compliance with these standards not only ensures product integrity but also builds trust with partners and clients. Real-world experiences from industry professionals reveal that incorporating automatic clippers can drastically reduce labor costs associated with traditional clipping methods. This reduction in variable costs, paired with the machine's high throughput, translates into significant economic benefits over time. Companies leveraging these advancements can effectively allocate resources towards innovation and market expansion, thus positioning themselves strategically within the global market. In summation, the sausage automatic clipper is not just a tool; it is an investment in innovation, quality, and trust. For manufacturers aiming to transform their production processes, understanding and embracing this technology is essential in achieving operational excellence and securing a future where demand continues to grow, and consumer expectations evolve.

Authoritative reports in the field suggest a rise in demand for automated solutions as consumers become increasingly health-conscious and demand transparency in food production processes. Consequently, the ability of the automatic sausage clipper to deliver consistent and hygienic results strengthens a brand’s reputation in demonstrating product reliability and consumer safety. Trustworthiness is underscored by the machine’s ability to consistently output top-quality products. Investment in such technology conveys a commitment to excellence and adherence to industry standards, fostering consumer confidence. These machines are often subject to stringent international norms for food safety and hygiene; thus, compliance with these standards not only ensures product integrity but also builds trust with partners and clients. Real-world experiences from industry professionals reveal that incorporating automatic clippers can drastically reduce labor costs associated with traditional clipping methods. This reduction in variable costs, paired with the machine's high throughput, translates into significant economic benefits over time. Companies leveraging these advancements can effectively allocate resources towards innovation and market expansion, thus positioning themselves strategically within the global market. In summation, the sausage automatic clipper is not just a tool; it is an investment in innovation, quality, and trust. For manufacturers aiming to transform their production processes, understanding and embracing this technology is essential in achieving operational excellence and securing a future where demand continues to grow, and consumer expectations evolve.

Next: