12-р сар . 14, 2024 09:09 Back to list

chicken breast flattening factory

The Chicken Breast Flattening Factory A Pillar of Efficiency in Poultry Processing

In the bustling world of poultry processing, the demand for high-quality and uniformly shaped chicken breast has surged over recent years. To meet this demand and optimize production, many manufacturers have turned to specialized practices and technologies. One notable innovation in this field is the chicken breast flattening factory—an establishment dedicated to streamlining the preparation of chicken breasts for both retail and food service industries.

At the core of the chicken breast flattening process is the need for efficiency and consistency. Typically, chicken breasts come in various sizes and thicknesses, which can complicate cooking times and presentation. By flattening the chicken breasts, processors can create a product that offers uniform thickness, ensuring even cooking and enhanced flavor absorption during marination. Flattened chicken breasts are not only aesthetically pleasing but also cater to the culinary demands of various recipes, from grilled dishes to stir-fries.

The operations within a chicken breast flattening factory are both intricate and efficient. Upon arrival, chicken breasts are first inspected for quality. This is crucial, as a high standard of meat quality is paramount in the poultry industry. Once sorted, the chicken breasts are typically washed and sanitized to ensure that they are free from any contaminants. This reflects the industry's commitment to food safety and hygiene, which are critical elements in meat processing.

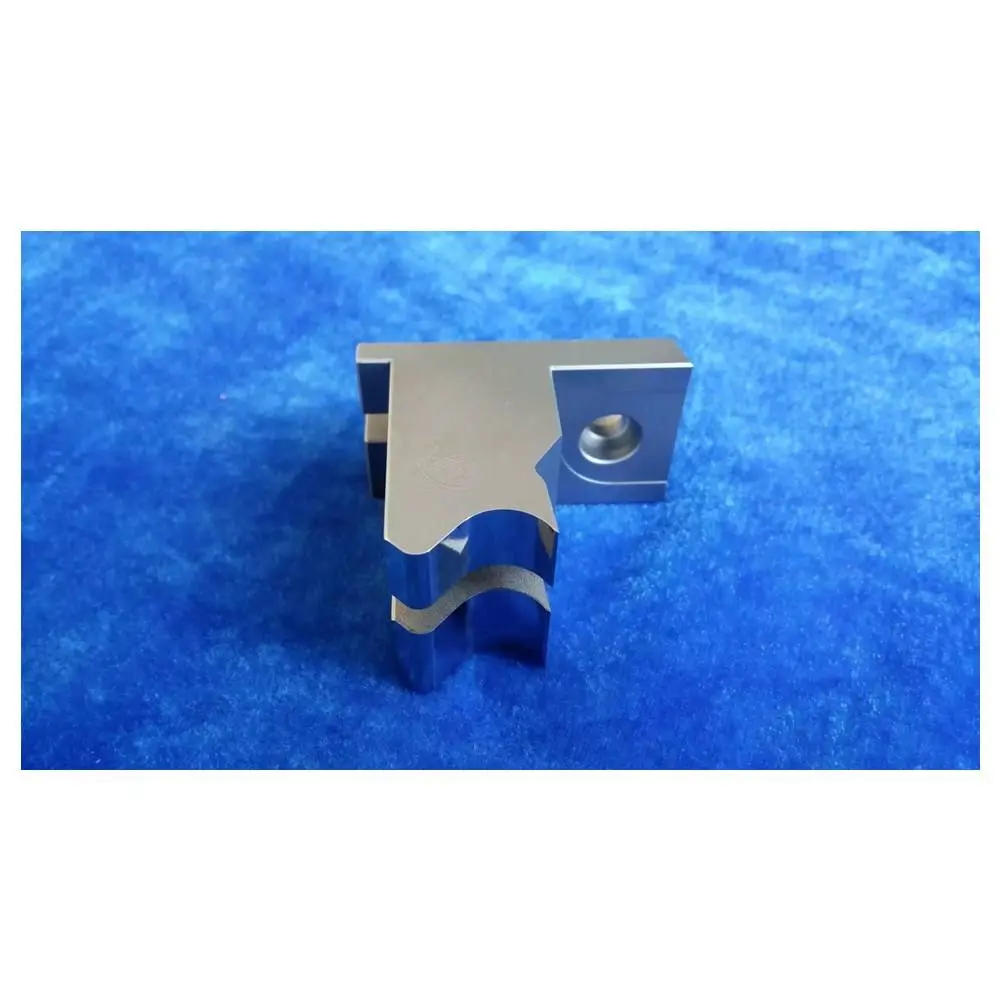

After the initial quality control measures, the chicken breasts undergo a flattening process. This is achieved through the use of specialized machines designed to apply uniform pressure to the meat. These machines not only ensure consistency in thickness but also reduce the physical labor required compared to manual methods. The flattened breasts are carefully packaged to maintain freshness and are often vacuum-sealed, prolonging shelf life and making them ready for distribution.

chicken breast flattening factory

One of the significant advantages of a chicken breast flattening factory is its ability to cater to the specific needs of clients

. Restaurants and grocery stores often request flattened chicken breasts for particular dishes. By offering customization options, factories can enhance customer satisfaction and establish long-term relationships with their clients.Moreover, the factory's operations contribute to sustainable practices within the poultry industry. By optimizing the size and reducing waste during chicken processing, flattening factories ensure that more of the bird is utilized efficiently. This not only maximizes the yield but also minimizes the environmental impact associated with poultry farming.

In addition to the operational efficiency and sustainability aspects, the success of a chicken breast flattening factory relies heavily on skilled personnel. From machine operators to quality control inspectors, the workforce plays a vital role in maintaining the production standards and ensuring that the final product meets both safety regulations and customer expectations.

In conclusion, the chicken breast flattening factory is a crucial component in modern poultry processing. By implementing advanced technologies and efficient processes, these factories produce high-quality, uniformly flattened chicken breasts that meet the rising consumer demand. As the culinary landscape continues to evolve, the role of such specialized facilities will only become more significant, paving the way for innovations that prioritize efficiency, quality, and sustainability in the meat-processing industry. The commitment to excellence within these factories not only benefits producers but also enhances the dining experience for consumers, showcasing the harmony between industrial efficiency and culinary artistry.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025