नोभ . 06, 2024 19:09 Back to list

Leading Manufacturer of Industrial Tumbling Machines for Efficient Processing Solutions

Industrial Tumbling Machine Manufacturer Revolutionizing Surface Finishing

In the world of manufacturing, maintaining high standards of product quality and finish is crucial. One innovative solution that has gained significant attention is the industrial tumbling machine. This equipment is pivotal in various industries, including automotive, aerospace, and metalworking, where achieving a superior surface finish is a necessity. As the demand for sophisticated finishing techniques grows, the role of industrial tumbling machine manufacturers becomes increasingly vital.

What is an Industrial Tumbling Machine?

An industrial tumbling machine is a type of mass finishing equipment that utilizes mechanical action to improve the surface finish of manufactured parts. The process involves placing parts in a rotating drum or bowl, along with abrasive media, to polish, deburr, or clean surfaces. The tumbling action allows for uniform exposure of the parts to the abrasives, ensuring consistent results across all items.

Advantages of Using Tumbling Machines

1. Efficiency Tumbling machines can process numerous parts simultaneously, significantly increasing productivity compared to manual finishing methods. This industrial efficiency makes them indispensable for large-scale manufacturing operations.

2. Consistency One of the primary benefits of using tumbling machines is their ability to produce uniform results. This consistency reduces the likelihood of defects and enhances the overall quality of the finished products.

3. Versatility Industrial tumbling machines are highly adaptable and can be used for various tasks, including deburring, polishing, and cleaning. Different media types and sizes can be employed depending on the specific requirements of the parts being processed.

4. Reduced Labor Costs By automating the finishing process, tumbling machines minimize the need for manual labor, leading to lower operational costs. This cost-effectiveness is particularly appealing to manufacturers looking to optimize their production processes.

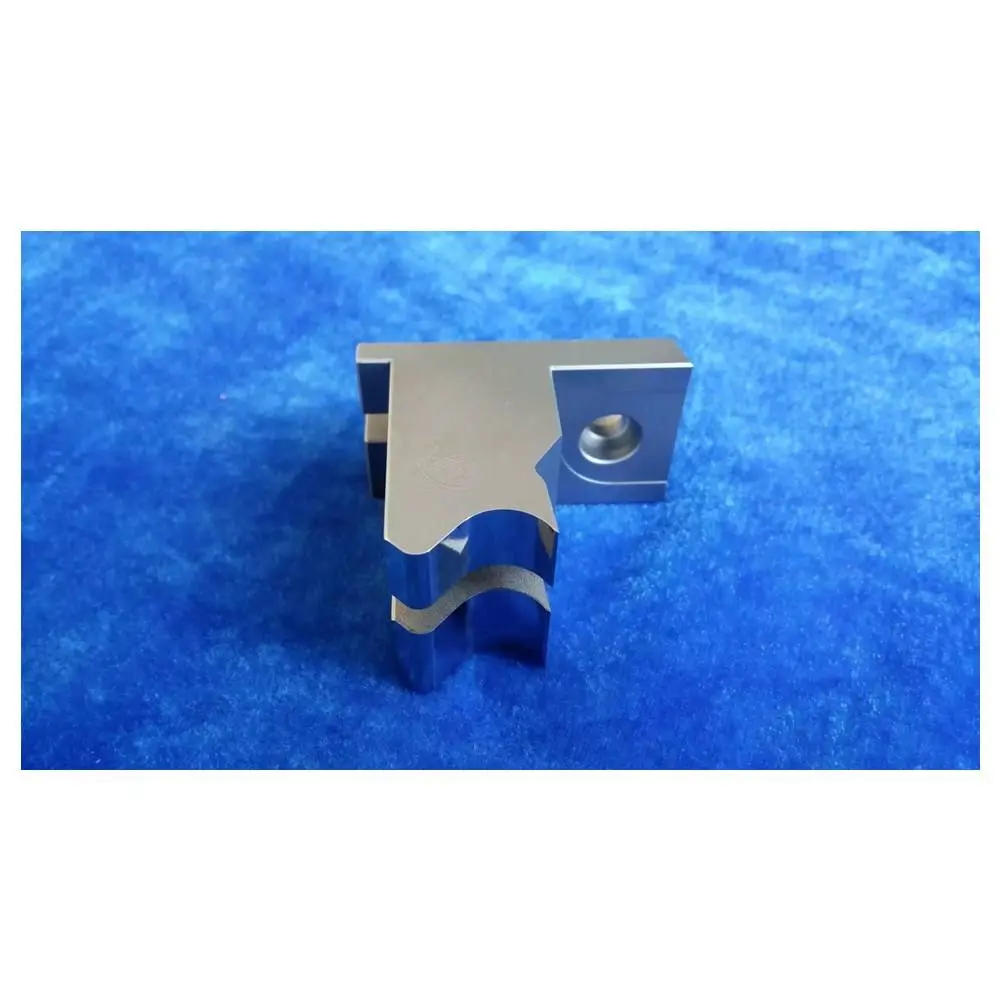

industrial tumbling machine manufacturer

Choosing the Right Manufacturer

When selecting an industrial tumbling machine manufacturer, several factors come into play. A reputable manufacturer should provide high-quality machinery tailored to the specific needs of different industries. Here are some key points to consider

- Experience Look for manufacturers with a proven track record in the industry. Experience often correlates with a better understanding of client needs and the technological advancements necessary for optimal machine performance.

- Customization Options Different industries have unique requirements for surface finishing. A good manufacturer should offer customizable solutions that cater to specific applications, whether it's for delicate components or robust industrial parts.

- Customer Support Strong customer support is essential for the long-term success of any machine investment. Manufacturers should provide training, maintenance, and readily available spare parts to ensure the machines operate smoothly.

- Innovative Technologies The best manufacturers stay ahead of industry trends and invest in research and development. Innovative technologies, such as programmable controls and advanced media options, can significantly enhance the tumbling process, leading to superior results.

Conclusion

Industrial tumbling machines are transforming the landscape of surface finishing across various sectors. Their ability to deliver high-quality results efficiently makes them an essential asset for manufacturers striving for excellence in production. As companies increasingly seek to enhance their operational processes, partnering with a reputable industrial tumbling machine manufacturer can lead to improved product quality and overall competitiveness in the market.

The key to success lies in understanding the unique needs of your manufacturing processes and choosing a manufacturer that aligns with those requirements. With advancements in technology, the future of industrial tumbling machines looks promising, offering further enhancements in efficiency, consistency, and overall performance. Investing in the right machinery will not only streamline production but also pave the way for a brighter, more efficient manufacturing future.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025