नोभ . 20, 2024 01:12 Back to list

vacuum tumbler for meat processing manufacturer

The Importance of Vacuum Tumblers in Meat Processing A Manufacturer's Perspective

In the modern meat processing industry, efficiency and quality are paramount. As consumers become increasingly discerning about the meat products they purchase, manufacturers must rely on advanced technologies that enhance flavor, texture, and shelf life. One such technology that has gained popularity is the vacuum tumbler. This article explores the significance of vacuum tumblers for meat processing manufacturers, detailing their benefits, working principles, and considerations in selecting the right equipment.

What is a Vacuum Tumbler?

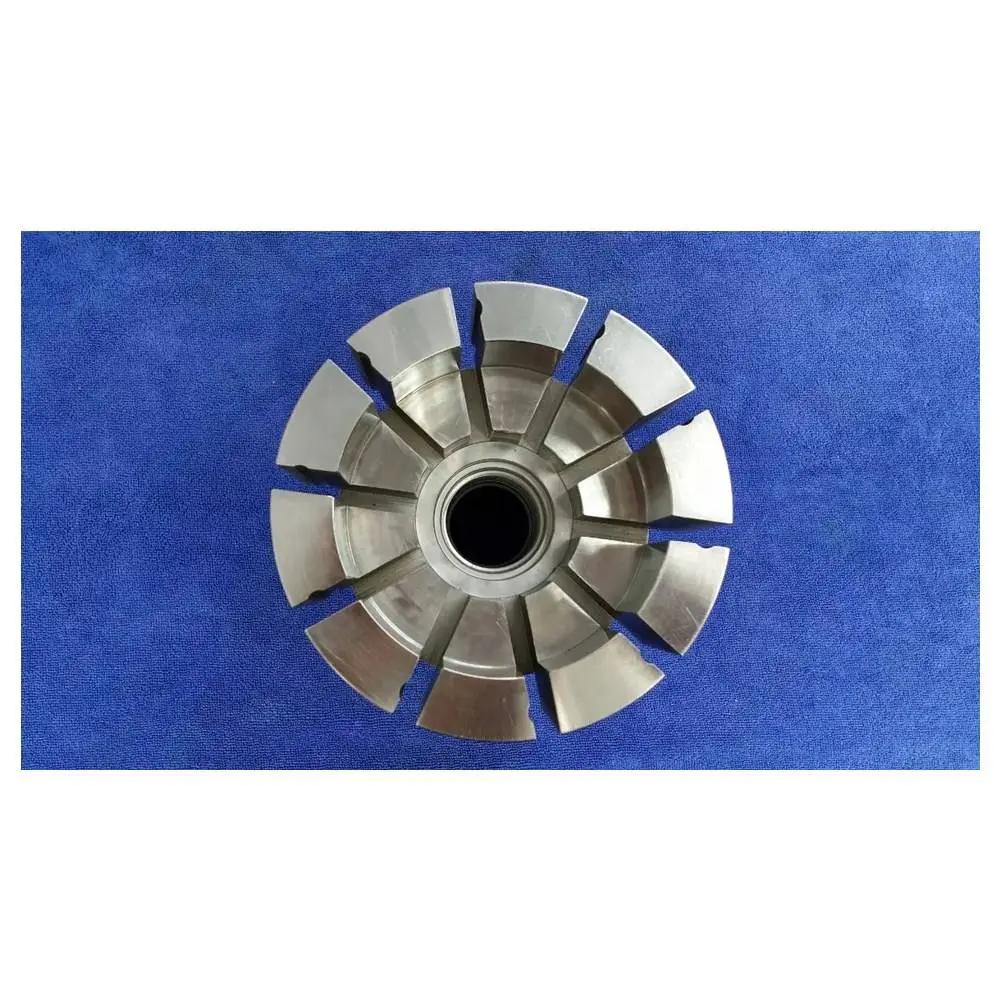

A vacuum tumbler is a specialized machine designed for the marination and curing of meat products. It utilizes a combination of vacuum and mechanical tumbling action to ensure that brine, spices, and other flavoring agents penetrate the meat effectively. This process not only enhances flavor but also improves the texture and juiciness of the final product.

How Vacuum Tumblers Work

The operation of a vacuum tumbler is relatively straightforward but highly effective

1. Marinade Preparation The process begins with the preparation of the marinade, which can include water, salt, sugars, spices, and other flavor enhancers. The specific ingredients will depend on the desired flavor profile of the final meat product.

2. Vacuum Sealing Once the marinade and meat are combined in the tumbler, the machine creates a vacuum environment. This removal of air allows for deeper penetration of the marinade into the meat, which is especially critical for large cuts that would otherwise not absorb flavor effectively.

3. Tumbling Action The tumbler then rotates, agitating the meat and marinade mix. This mechanical action not only aids in marination but also helps to tenderize the meat by breaking down muscle fibers and connective tissue.

4. Resting Phase After tumbling, the meat typically undergoes a resting phase within the vacuum environment, allowing even more time for the flavors to meld and the meat to absorb the marinade fully.

Benefits of Using Vacuum Tumblers

vacuum tumbler for meat processing manufacturer

2. Consistent Results Vacuum tumblers provide uniform distribution of the marinade, ensuring that each piece of meat is evenly seasoned. This consistency is vital for manufacturers aiming to meet customer expectations.

3. Time Efficiency The vacuum and tumbling process can substantially reduce marination time compared to traditional methods, allowing manufacturers to process larger quantities of meat in a shorter timeframe.

4. Improved Yield By effectively injecting moisture and flavor into the meat, vacuum tumblers can lead to an increase in yield, as the meat retains more moisture during cooking and handling.

5. Versatility These machines are not limited to beef or pork; they can be used for poultry and fish, making them a versatile choice for diverse meat processing operations.

Choosing the Right Vacuum Tumbler

When selecting a vacuum tumbler, manufacturers should consider several factors

1. Capacity Assess the volume of meat to be processed regularly. Tumblers come in various sizes, and choosing the right capacity is vital for operational efficiency.

2. Material Quality Look for tumblers made from high-quality stainless steel and materials that can withstand the rigors of a meat processing environment, ensuring longevity and hygiene.

3. Technology and Features Modern vacuum tumblers come with advanced features such as programmable settings, automatic vacuum control, and user-friendly interfaces, which can enhance productivity and ease of use.

4. Service and Support Choosing a manufacturer that provides solid customer support and service is essential for maintenance and troubleshooting.

Conclusion

In the highly competitive meat processing industry, employing efficient methods such as vacuum tumblers can provide manufacturers with a distinct edge. By enhancing flavor, improving tenderness, and increasing processing speed, these machines have become an indispensable tool for achieving high-quality meat products. As the industry continues to evolve, embracing such technology will be crucial for meeting consumer demands and ensuring business success.