Jul . 29, 2024 00:26 Back to list

Comprehensive Price List for Frozen Meat Cutting Machines and Related Equipment

Understanding the Price List of Frozen Meat Cutting Machines

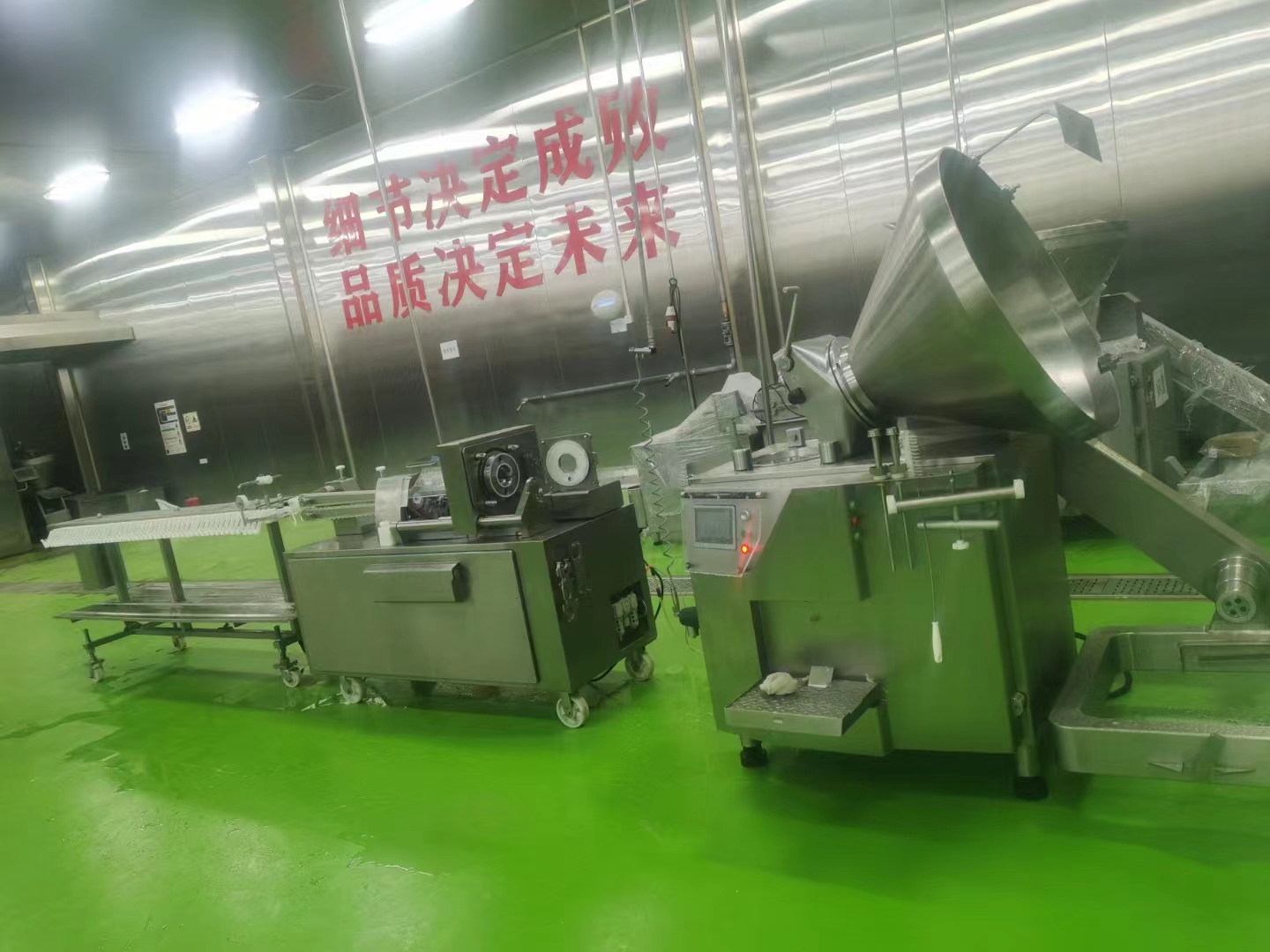

In the contemporary food processing industry, the efficiency, safety, and precision afforded by advanced machinery have become imperative. A significant piece of this machinery is the frozen meat cutting machine, designed to handle the challenges posed by frozen meat — which can be notoriously difficult to cut with traditional tools. This article delves into the essential factors influencing the pricelist of frozen meat cutting machines.

The Importance of Frozen Meat Cutting Machines

Frozen meat cutting machines serve a crucial role in meat processing facilities, restaurants, and large-scale catering services. The cutting process must ensure that meat is cut uniformly and efficiently to meet food safety standards and maintain product quality. These machines not only elevate operational efficiency but also enhance the overall quality of meat products.

Factors Affecting the Price of Frozen Meat Cutting Machines

1. Type and Capacity The type of frozen meat cutting machine significantly affects its price. Machines can range from small, manual models suitable for local butcher shops to large automated machines designed for industrial use. The capacity of the machine is crucial; systems designed to handle larger volumes will naturally be priced higher due to increased material costs and technology integration.

2. Technology and Features Machines equipped with advanced technology such as programmable logic controllers (PLCs), automated feeding systems, and cutting precision features will also command higher prices. The integration of smart technology that ensures optimal cutting angles and reduces waste adds value, thus increasing the machine's price.

3. Brand and Manufacturer Reputation Established manufacturers with a reputation for quality and reliability often charge more for their products. These companies typically invest heavily in research and development, ensuring that their machines meet the high standards of the food processing industry.

frozen meat cutting machine pricelist

4. Materials and Durability The construction materials of the machine play a pivotal role in its longevity and performance. Stainless steel, for instance, is a common choice for these machines due to its resistance to rust and corrosion. While machines built with high-quality materials may have a higher upfront cost, they often result in lower maintenance costs over time.

5. Maintenance and Support The availability of after-sales service and maintenance support can also influence the pricing of frozen meat cutting machines. Machines that offer robust customer support, warranty options, and easy access to spare parts might have a higher initial cost but provide peace of mind and reliability in the long run.

6. Market Trends The dynamic nature of the food processing market and technological advancements also affect pricing. As new features and technologies emerge, older models may decrease in price, while cutting-edge machines with the latest innovations may see price increases.

Typical Price Ranges

The price of frozen meat cutting machines can vary significantly based on the aforementioned factors. For entry-level, smaller machines, prices can start at around $1,500 to $5,000. Mid-range models designed for small to medium businesses might range from $5,000 to $15,000, while high-end industrial frozen meat cutting machines can cost upwards of $20,000 to $100,000, depending on their capabilities and specifications.

Conclusion

In conclusion, investing in a frozen meat cutting machine is essential for any business that handles frozen meat. Understanding the various factors that influence pricing can help prospective buyers make informed decisions. While upfront costs may seem substantial, the long-term benefits of efficiency, safety, and quality assurance make these machines an invaluable asset in the meat processing industry.