Aug . 06, 2024 09:36 Back to list

Exploring Bulk Grinding Equipment Solutions for Efficient Wholesale Processing Needs in Various Industries

The Importance of Wholesale Grinder Machines in Modern Industries

In today's rapidly evolving industrial landscape, the demand for efficient and reliable machinery is greater than ever. Among the essential equipment utilized in various manufacturing processes, wholesale grinder machines stand out as critical tools for a wide range of applications. These machines are designed to grind, reduce, and process materials into finer particles, significantly enhancing productivity and ensuring high-quality output. This article will explore the significance of wholesale grinder machines, their types, applications, and the benefits they offer to businesses.

Understanding Wholesale Grinder Machines

Wholesale grinder machines are typically sold in bulk to businesses that require substantial quantities of grinding equipment for large-scale operations. These machines come in various types, including hammer mills, roller mills, and ball mills, each designed to cater to specific grinding needs. Hammer mills utilize rapidly spinning hammers to crush materials, whereas roller mills use cylindrical rollers to achieve a finer consistency. Ball mills, on the other hand, rely on the impact of balls within a rotating cylinder to grind materials to a desired particle size.

Key Applications of Grinder Machines

Grinder machines find applications across diverse industries, including food processing, pharmaceuticals, mining, and construction. In the food industry, they are used to grind grains, spices, and other ingredients to ensure uniform texture and flavor. The pharmaceutical sector relies on grinder machines for the production of powders from tablets and other solid forms, facilitating effective dosage and absorption.

In mining, grinder machines play a crucial role in the comminution process, where raw materials are broken down into smaller sizes for further processing. Construction industries utilize these machines for grinding materials such as concrete, asphalt, and aggregates to ensure precise mixing and consistency in building projects.

Benefits of Using Wholesale Grinder Machines

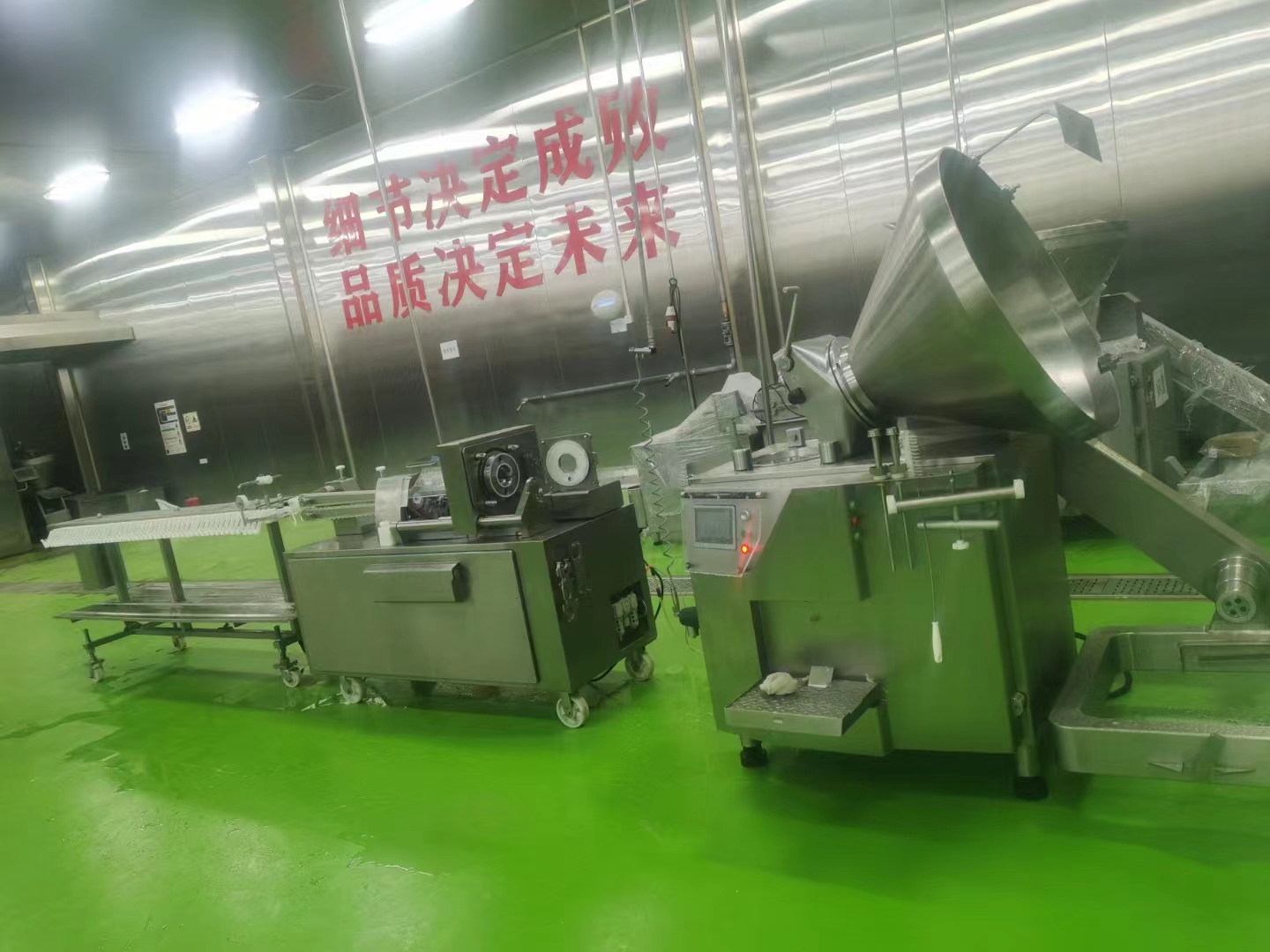

wholesale grinder machine

1. Cost-Effectiveness Purchasing grinder machines wholesale allows businesses to save costs significantly. Bulk buying reduces the per-unit price, enabling companies to allocate their resources more effectively. This is particularly advantageous for startups and smaller businesses looking to maximize their investments.

2. Consistency in Quality One of the primary advantages of using grinder machines is their ability to produce consistent results. The precision offered by modern grinder technology ensures that materials are ground to uniform sizes, leading to improved quality in the end product. This consistency is vital in industries where quality control is paramount.

3. Increased Efficiency Wholesale grinder machines are designed for high-volume production, significantly enhancing operational efficiency. With faster processing times and the ability to handle large quantities of material, these machines help businesses meet their production demands without compromising on quality.

4. Versatility Another notable benefit is the versatility of grinder machines. They can be used to process a wide variety of materials, making them suitable for multiple industries. This adaptability enables businesses to diversify their offerings and explore new market opportunities.

5. Reduced Labor Costs Automation and advanced technology in modern grinder machines mean that less manual labor is required. This not only reduces labor costs but also minimizes the risk of workplace injuries associated with manual grinding processes.

Conclusion

Wholesale grinder machines are an indispensable asset in modern industrial operations, driving efficiency, consistency, and cost savings. As businesses continue to seek ways to optimize their production processes, the importance of investing in high-quality grinding equipment cannot be overstated. By leveraging the benefits of wholesale grinder machines, companies can enhance their manufacturing capabilities and stay competitive in an increasingly demanding market. Whether in food production, pharmaceuticals, mining, or construction, these machines remain at the forefront of industrial innovation.