Aug . 09, 2024 01:45 Back to list

Innovative Manufacturer of High-Quality Meat Buggy Lifters for Efficient Food Processing Solutions

The Rise of Meat Buggy Lifters Revolutionizing Meat Processing with Innovative Manufacturing

In the ever-evolving landscape of the meat processing industry, efficiency, safety, and innovation remain paramount. Among the latest advancements in this field, meat buggy lifters have emerged as transformative tools, streamlining operations and improving worker safety. This article explores the significance of meat buggy lifters, the manufacturing process behind them, and their impact on the meat industry.

What is a Meat Buggy Lifter?

A meat buggy lifter is an industrial device designed to safely transport and lift heavy loads of meat products from processing stations to storage areas or transport vehicles. This equipment typically consists of a hydraulic lifting system mounted on a mobile platform, allowing for easy maneuverability. Meat buggy lifters are essential in places such as slaughterhouses, meat processing plants, and distribution centers, where heavy and bulky products are regularly handled.

The Need for Meat Buggy Lifters

Traditionally, meat processing involved manual handling, which not only posed safety risks but also decreased productivity. Workers often faced physical strain and potential injuries while lifting and moving heavy loads. With the increasing demand for meat products globally, companies needed a solution that mitigated these risks while enhancing operational efficiency.

Meat buggy lifters address these challenges by reducing the manual labor required in handling meat. Equipped with hydraulic systems, these lifters enable workers to quickly and safely elevate heavy products, minimizing stress on their bodies. Consequently, the implementation of meat buggy lifters has led to a reduction in workplace injuries and an increase in overall productivity.

The Manufacturing Process

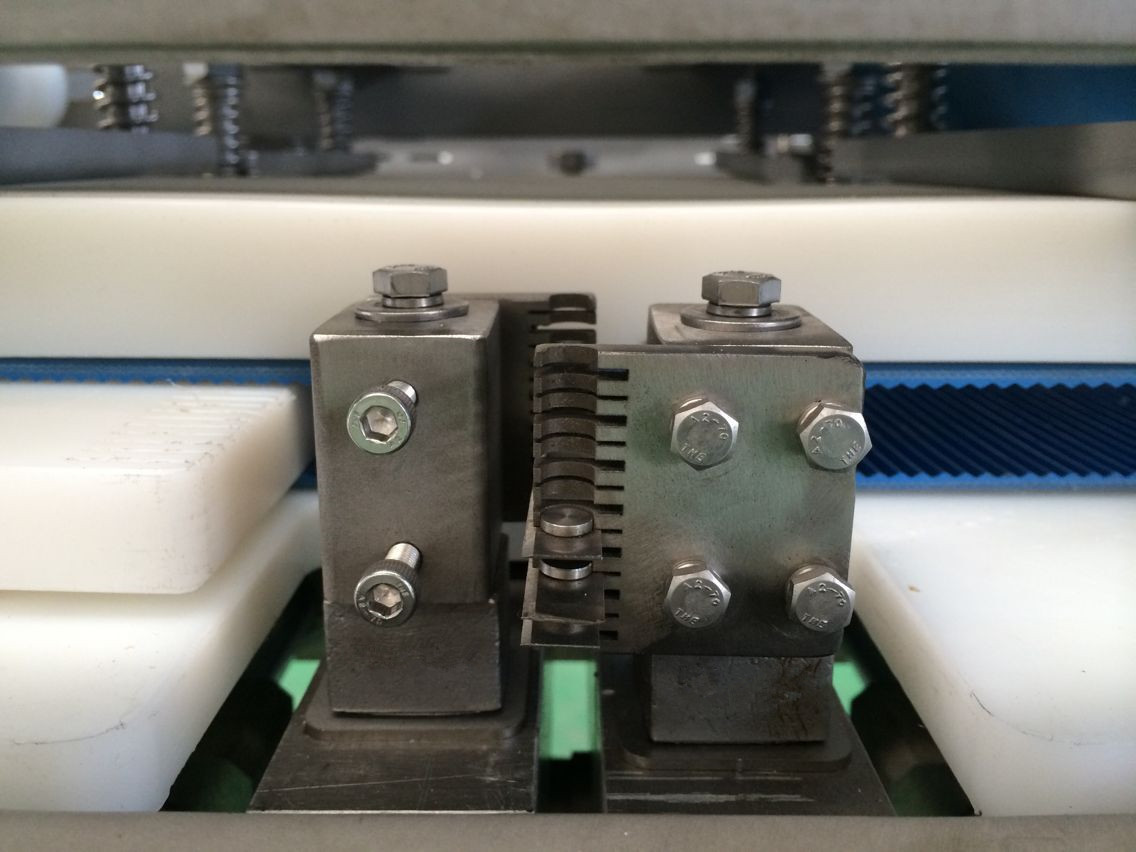

meat buggy lifter manufacturer

The development of a meat buggy lifter incorporates several key manufacturing processes. Manufacturers begin by designing the lifters using advanced CAD (Computer-Aided Design) software, ensuring that the final product meets industry standards and safety regulations. Materials used in constructing meat buggy lifters are chosen for their durability and resistance to corrosion, given the often-harsh environments of meat processing facilities.

Once the design is finalized, parts are manufactured using precision machining techniques. High-strength steel is commonly utilized for the frame, while hydraulic systems are engineered to deliver the necessary lifting power. Quality control is integral at every stage of manufacturing, ensuring that each component meets strict safety and performance criteria.

After assembly, meat buggy lifters undergo rigorous testing to verify their functionality and safety. Manufacturers often simulate real-world conditions to ensure that the equipment can perform effectively under the pressures of meat processing. Upon passing these tests, the machines are ready for deployment to meat processing facilities.

Impact on the Meat Industry

The introduction of meat buggy lifters has significantly impacted the meat industry. By automating the lifting and transportation of heavy products, these devices have led to faster processing times and increased output. Moreover, they contribute to a safer working environment, which can improve employee morale and reduce turnover rates.

In an age where sustainability is a growing concern, meat buggy lifters also play a role in reducing waste. By optimizing the handling of meat products, they help streamline operations, leading to more efficient use of resources and less spoilage.

Conclusion

As the meat processing industry continues to evolve, the role of innovative equipment like meat buggy lifters cannot be overstated. The manufacturing of these machines reflects a commitment to safety, efficiency, and productivity. By investing in advanced lifting technologies, meat processing plants are not only enhancing their operational capabilities but are also setting new standards in worker safety. As demand for meat products grows worldwide, the significance of meat buggy lifters will only continue to rise, showcasing the importance of innovation in meeting the challenges of the industry.