Jul . 25, 2024 05:45 Back to list

Leading Manufacturers of Food Processing Machinery for High-Quality Production and Efficiency Solutions

The Growing Landscape of Food Processing Machinery Manufacturers

In an ever-evolving global food industry, the role of food processing machinery manufacturers is becoming increasingly pivotal. With the rising demand for processed food products, driven by urbanization, changing consumer preferences, and the need for efficient production methods, these manufacturers are at the forefront of innovation and technology.

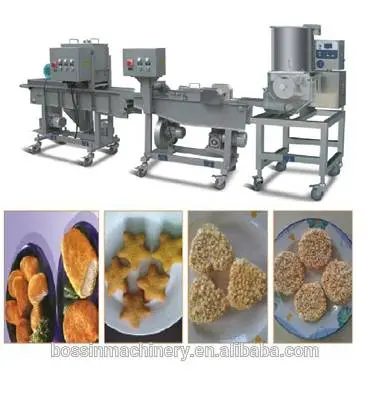

Understanding Food Processing Machinery

Food processing machinery encompasses a wide range of equipment designed to convert raw ingredients into food products. This machinery is used for various applications, including mixing, cooking, sterilizing, packaging, and preserving food. The machines vary in size and complexity, ranging from simple manual devices to sophisticated automated systems that integrate artificial intelligence.

The importance of these machines cannot be overstated. They help enhance food safety, improve product quality, and increase production efficiency. As population growth accelerates, manufacturers are under pressure to ramp up production while maintaining stringent quality standards. This demand creates opportunities for manufacturers to innovate and improve their machinery.

Innovations in Food Processing Machinery

With technological advancements and increased automation, food processing machinery manufacturers are continually refining their products. Some of the latest trends include the incorporation of smart technology and IoT (Internet of Things) systems into machinery. These innovations allow for remote monitoring and management of production lines, leading to optimized resource usage and better waste management.

Moreover, advancements in machine design are focusing on energy efficiency. New technologies, such as energy recovery systems and more efficient motors, help manufacturers reduce their operational costs while minimizing their environmental footprint. In an era where consumer awareness of sustainability is rising, manufacturers are increasingly adopting eco-friendly practices in their production processes.

food processing machinery manufacturers

Customization and Flexibility

Today's market demands flexibility, and food processing machinery manufacturers are responding by offering customized solutions tailored to specific industry needs. Whether it's accommodating different food types, varying batch sizes, or unique processing requirements, manufacturers are focusing on creating adaptable machines. This customization allows food producers to be more responsive to market trends and consumer preferences.

For example, with the rise of plant-based diets, equipment needs have shifted significantly. Manufacturers are now designing machines that can handle alternative proteins, requiring different processing techniques compared to traditional meat products. This adaptability extends beyond design; manufacturers also provide training and ongoing support to ensure their clients can maximize machine utility.

Challenges Facing Manufacturers

Despite the exciting landscape, food processing machinery manufacturers face several challenges. Rapid technological changes require continuous investment in research and development. Moreover, the supply chain disruptions, especially in the wake of global events like the COVID-19 pandemic, have introduced unpredictability in sourcing materials and components.

Additionally, manufacturers must navigate varying regulatory requirements across different countries, which can complicate the export and import of machinery. Staying compliant while meeting the evolving needs of their clients demands resilience and ingenuity.

Conclusion

As the food industry continues to expand and evolve, food processing machinery manufacturers will play a crucial role in shaping its future. Their ability to innovate and adapt to new challenges and trends will determine not only their success but also the efficiency and sustainability of food production processes worldwide. The synergy between technological advancement and the food manufacturing sector is setting the stage for a promising future, ensuring that the world can meet its food requirements effectively and responsibly.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025