Aug . 09, 2024 16:55 Back to list

Leading Manufacturers of Meat and Poultry Flattening Machines for Efficient Food Processing Solutions

The Rise of Meat and Poultry Flattening Machines in the Food Industry

In the fast-evolving world of food production, efficiency and quality are paramount. Among the myriad of technologies shaping the industry, meat and poultry flattening machines have emerged as crucial players in enhancing processing efficiency and maintaining product quality. These machines are specifically designed to improve the preparation of meat and poultry products, ensuring uniform thickness that meets both consumer preferences and cooking standards.

Flattening machines serve several key purposes in meat and poultry processing facilities. One of the primary advantages is the ability to achieve a consistent thickness across products. This uniformity not only improves the visual appeal of the meat but also ensures even cooking. Consumers increasingly demand high-quality, aesthetically pleasing products, and manufacturers aim to meet these expectations. Whether for a restaurant kitchen or a retail packaging line, flattened meat cuts cook more evenly, reducing the risk of undercooked sections which can be a health hazard.

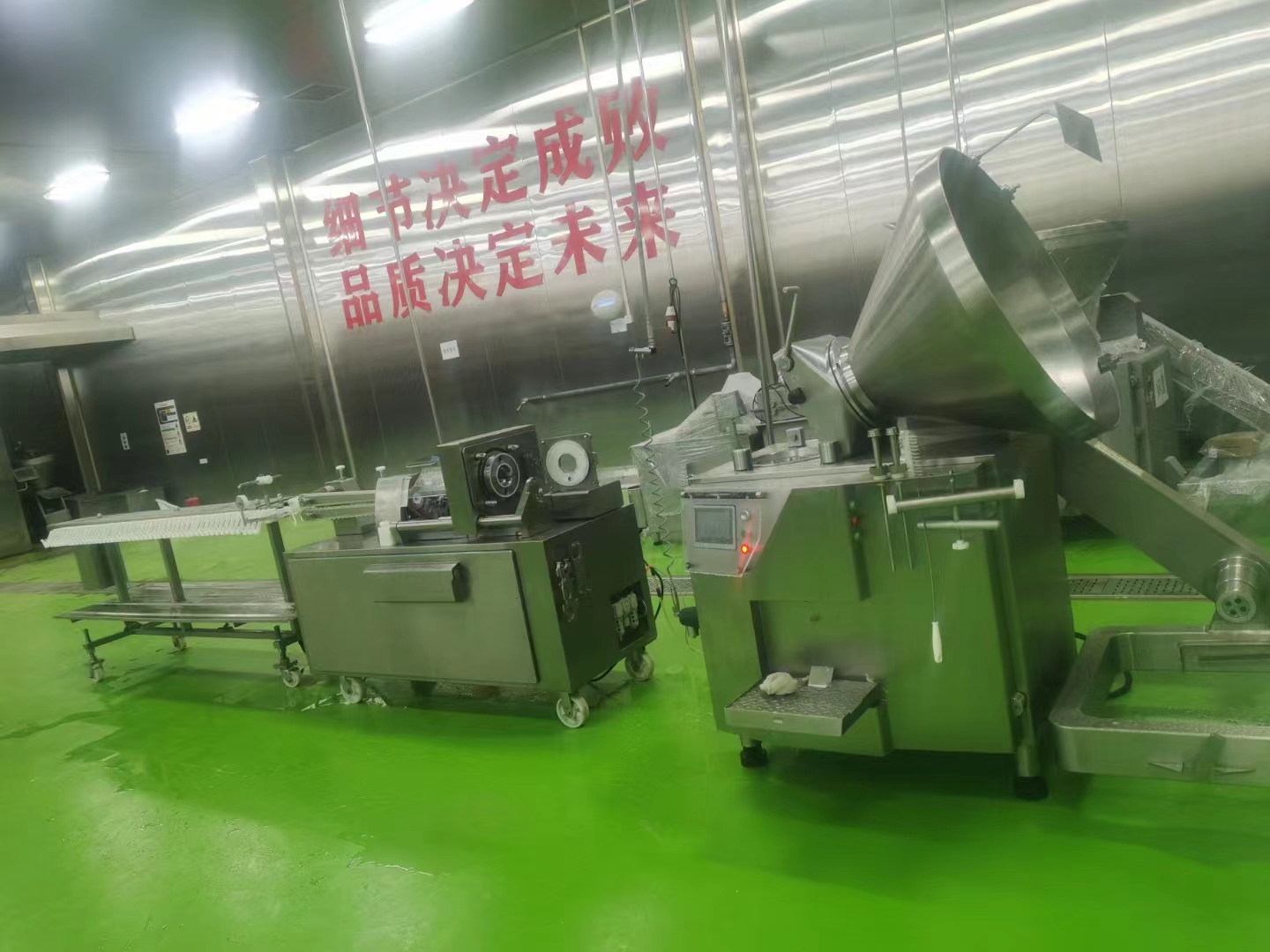

The process of flattening meat and poultry typically involves the use of rollers or press mechanisms to flatten the cuts. These machines can handle various types of meats, including chicken breasts, pork chops, and beef steaks, making them versatile tools in a factory setting. Additionally, many modern flattening machines are equipped with adjustable settings, allowing operators to customize the thickness based on the specific requirements of their products. This adaptability is essential in meeting the diverse demands of different markets, from fast food chains to gourmet restaurants.

meat poultry flattening machine factories

Moreover, the adoption of flattening machines leads to significant labor savings. Traditionally, flattening meat would require skilled labor, which is not only time-consuming but can also lead to inconsistencies in the final product. Automation through flattening machines reduces the need for human intervention, allowing workers to focus on other essential tasks in the production line. This shift not only enhances productivity but also contributes to a safer working environment, as there is less manual handling involved in preparing the meat.

Another significant benefit of meat and poultry flattening machines is their contribution to waste reduction. By ensuring consistent sizes and shapes, these machines help optimize the use of raw materials. Reduced wastage means that manufacturers can achieve better margins, making their operations more economically viable. Additionally, a standardized product can enhance inventory management and reduce storage costs, as uniform items can be stacked and stored more efficiently.

Furthermore, as consumer preferences shift towards processed and ready-to-cook meals, the demand for flattened meat products has surged. Suppliers are responding to this trend by implementing advanced technologies that increase production capacity without compromising quality. Factories are investing in cutting-edge flattening machines that incorporate features like hygiene controls, quick changeover capabilities, and enhanced productivity metrics, all of which support the modern food processing environment's requirements.

In conclusion, meat and poultry flattening machines are revolutionizing the food processing industry. By enhancing product uniformity, improving cooking safety, increasing labor efficiency, and reducing waste, these machines are indispensable tools for factories looking to thrive in a competitive market. As technology continues to advance, we can expect further innovations in this area, leading to even more efficient and high-quality meat and poultry processing practices. The future of food production is poised to be shaped by such transformative innovations, driving the industry towards better standards and practices.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025