Dec . 05, 2024 00:20 Back to list

Supplier of Meat Flour Processing Equipment for Optimal Performance and Quality

The Rise of Meat Flourishing Machines Revolutionizing the Meat Processing Industry

In recent years, the meat processing industry has witnessed significant advancements in technology, leading to enhanced efficiency and quality. One such innovation is the meat flourishing machine, a specialized piece of equipment designed to improve the texture and flavor of meat products. As the demand for high-quality processed meats continues to rise, the role of meat flourishing machines is becoming more critical, driving suppliers to innovate and provide state-of-the-art solutions.

Understanding Meat Flourishing

Before delving into the specifics of suppliers and machines, it is essential to understand what meat flourishing involves. Flourishing, or marination, refers to the process of tenderizing meat and infusing it with flavors. Traditional techniques often involve manual methods, including the use of mallets or marinades rubbed into the surface. However, these methods can be labor-intensive and may not always achieve consistent results.

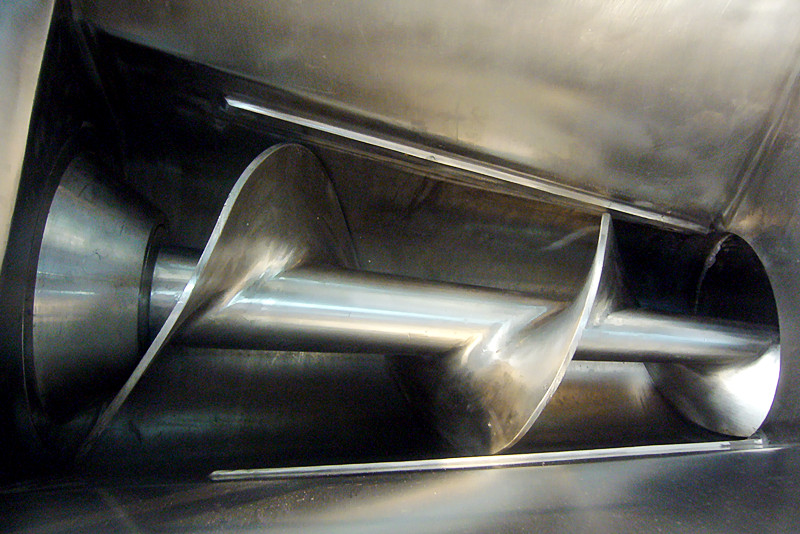

Meat flourishing machines automate this process, allowing for an even coating of marinades, tenderizers, and seasonings. These machines utilize advanced technologies such as vacuum infusion, tumbling, and needle injection to ensure that flavors penetrate deep into the meat fibers, resulting in a more flavorful and tender product.

The Benefits of Using Meat Flourishing Machines

1. Efficiency One of the primary advantages of meat flourishing machines is their ability to streamline the processing workflow. With the automation of the frosting process, manufacturers can significantly reduce the time and labor required, leading to faster turnaround times and higher productivity.

2. Consistency Manual methods can lead to inconsistent results due to human error. Meat flourishing machines offer precise control over the amount of seasoning and the infusion process, ensuring that each batch of meat has uniform flavor and texture. This consistency is crucial for businesses that rely on maintaining high standards for their products.

3. Flavor Enhancement By using advanced techniques such as vacuum infusion, these machines can introduce marinades and seasonings directly into the meat, enhancing flavor profiles that are often difficult to achieve with traditional methods. As a result, the end products meet consumer expectations for taste and quality.

meat flouring machine supplier

4. Reduced Waste Innovations in meat flourishing technology have also led to a reduction in food waste. By efficiently injecting marinades into the meat, less seasoning is required, and there is often a decrease in excess runoff, resulting in a more sustainable processing method.

The Growing Market for Meat Flourishing Machines

As consumer preferences evolve towards high-quality, flavorful meat products, the demand for meat flourishing machines has surged. Suppliers are recognizing this trend and investing in research and development to create more efficient and advanced machines. Numerous companies are now emerging as key players in this market, offering a range of models to cater to different processing capacities and types of meat products.

In addition to traditional suppliers, new start-ups are entering the market, focusing on innovative technologies that promise to revolutionize meat processing. These companies are often driven by sustainability goals and aim to reduce the ecological impact of meat production while maintaining product quality.

Choosing the Right Supplier

For businesses looking to invest in meat flourishing machines, selecting the right supplier is crucial. Key factors to consider include the supplier’s experience, technological expertise, customer support, and the availability of customized solutions. It is essential to choose a supplier that understands the specific needs of the business and can provide machines that enhance production efficiency without compromising quality.

Additionally, potential buyers should seek testimonials and case studies from other users to assess machine performance. Conducting thorough research and possibly visiting existing installations can provide valuable insights into the supplier’s reputation and the effectiveness of their machines.

Conclusion

The meat flourishing machine represents a significant leap forward in the meat processing industry, offering numerous advantages in efficiency, consistency, and flavor enhancement. As the market continues to grow, the importance of choosing a reliable supplier cannot be overstated. By leveraging these machines, businesses can enhance their product offerings, meet consumer demands for high-quality meat, and remain competitive in an evolving industry landscape. With continued advancements in technology and an increasing emphasis on sustainability, the future of meat processing looks promising.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|sausage production line,pneumatic technology

NewsAug.07,2025

-

Air-Free Vacuum Mixers for Precise & Homogeneous Blending

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Precision Clipping

NewsAug.06,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line Integration&Compact Design

NewsAug.06,2025

-

Automatic Deboner Machine for High-Yield Processing

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision and Efficiency

NewsAug.06,2025