Aug . 11, 2024 22:18 Back to list

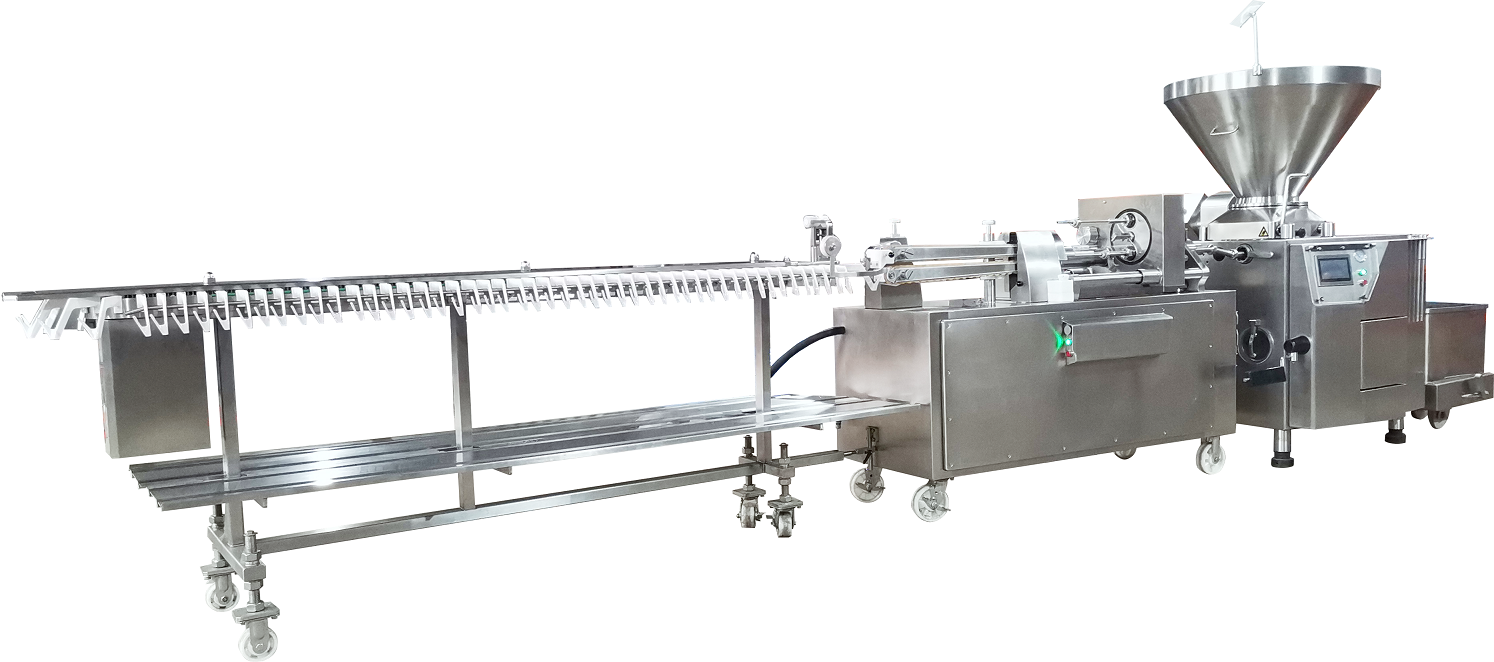

Pneumatic Sausage Tying Equipment Manufacturer for Efficient Production and Quality Assurance Solutions

The Innovations of Pneumatic Sausage Tying Machine Factories

In the bustling world of food production, efficiency and precision are paramount, particularly in the meat processing industry. One of the unsung heroes in this arena is the pneumatic sausage tying machine. These machines have revolutionized the way sausages are manufactured, ensuring consistency, speed, and superior quality. Today, we delve into the significance of pneumatic sausage tying machine factories and their contribution to modern food production.

Harnessing Pneumatic Power

Pneumatic sausage tying machines operate using compressed air, which allows them to orchestrate a series of motions with remarkable speed and accuracy. This technology eliminates the need for manual labor, reducing the risk of injury while simultaneously increasing production rates. The pneumatic mechanisms are designed to handle various types of casings and sausage styles, from traditional links to specialty products. As such, they cater to a diverse range of culinary preferences and market demands.

Enhancing Operational Efficiency

A major advantage of pneumatic sausage tying machines is their efficiency. In a factory setting, time is money, and the faster the production line can operate, the better the returns. These machines significantly cut down the time required for the tying process, which is traditionally labor-intensive. For instance, while a worker may take several seconds to manually tie each sausage, a pneumatic machine can accomplish this in a fraction of a second. This results in higher output levels without compromising quality.

Moreover, the use of pneumatic machines streamlines the workflow within a factory. Operators can set up the machine to tie sausages automatically, allowing them to focus on other aspects of the production process. With enhanced efficiency, factories can maximize their production capabilities, leading to reduced costs and increased profitability.

Precision and Quality Control

pneumatic sausage tying machine factory

Quality is an essential concern in food production, especially in the meat industry. Pneumatic sausage tying machines offer exceptional consistency in tying strength and tension, ensuring that each sausage is made with the same standards. This uniformity not only enhances the aesthetic appeal of the product but also contributes to longer shelf life. Consumers appreciate products that look good and taste great, and factories that invest in high-quality tying machines are more likely to meet these demands.

Additionally, the precision offered by these machines minimizes waste. By ensuring that each sausage is tied appropriately, there is less chance of filling spilling out during transport. This not only conserves resources but also promotes sustainability within the production process.

Customization and Technological Advances

Modern pneumatic sausage tying machines are equipped with advanced features that allow for extensive customization. Manufacturers can modify machine settings to accommodate various product specifications, including different casing types, sizes, and tying patterns. This adaptability is essential in today’s market, where consumers are increasingly looking for diverse and artisanal sausage options.

Furthermore, advancements in technology have led to the integration of smart systems into pneumatic machines. Features such as IoT connectivity enable real-time monitoring and diagnostics, allowing for proactive maintenance and minimizing downtime. Factories can respond swiftly to any issues, ensuring that production lines remain operational and efficient.

Conclusion

Pneumatic sausage tying machine factories represent a significant leap forward in food production technology. By harnessing the power of pneumatics, these machines enhance operational efficiency, precision, and quality control, benefiting both manufacturers and consumers alike. As the industry continues to evolve, the role of these innovative machines will undoubtedly become even more critical in meeting the ever-growing demand for high-quality meat products. Ultimately, pneumatic sausage tying machines not only streamline production but also exemplify the remarkable intersection of technology and tradition in the culinary world.