Aug . 17, 2024 03:34 Back to list

Sausage Filling Price List and Dosing Options for Your Needs

Understanding Sausage Dosing Fillers A Guide to Pricing and Selection

In the world of meat processing, the efficiency and quality of production are paramount. One crucial piece of equipment that helps achieve these goals is the sausage dosing filler. This machine plays an essential role in ensuring that sausages are filled uniformly, maintaining both taste and texture. As the industry continues to grow, understanding the factors that impact the pricing of sausage dosing fillers becomes increasingly important for producers at all levels.

What is a Sausage Dosing Filler?

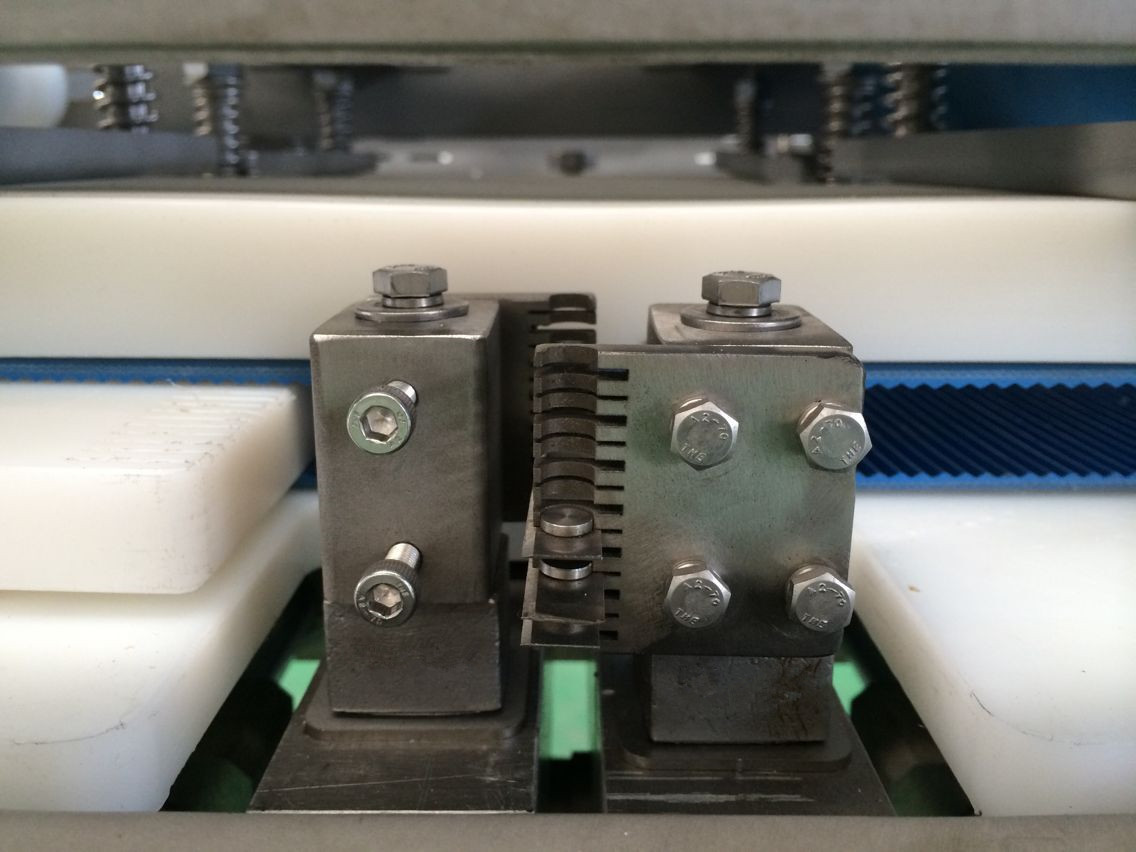

A sausage dosing filler is a specialized machine designed to fill casings with a precise amount of sausage mixture. This ensures that each sausage maintains a consistent weight and composition, which is vital for both quality control and regulatory adherence. These machines can vary widely in scale and complexity, from simple manual models to advanced automated systems equipped with programmable controls and enhanced safety features.

The Factors Influencing Pricing

1. Machine Type and Specifications The specifications of the sausage dosing filler primarily dictate its price. Manual fillers are typically less expensive but require more labor input and may not deliver the same level of precision as automated versions. On the other hand, fully automated fillers, while more costly upfront, can significantly increase production efficiency and consistency, leading to better long-term ROI.

2. Brand Reputation Established brands that have built a reputation for reliability and quality often price their machines higher due to the trust they command in the industry. Investing in well-known brands can ensure longevity and superior service and support, although the initial investment may be higher than lesser-known manufacturers.

sausage dosing filler pricelist

3. Customization Options Some manufacturers offer customizable features tailored to specific production needs. These can include adjustments for different filler sizes, speed alterations, or other enhancements. While customization can increase the initial cost, it can provide significant value by better aligning the machine with specific production requirements.

4. Material Quality The materials used in constructing the sausage dosing filler contribute to its durability and longevity. Stainless steel fillers are common due to their resistance to corrosion and ease of cleaning, but they are usually priced higher than those made from less durable materials. Investing in higher-quality materials can lead to reduced maintenance costs over time.

5. Technology and Features Advanced features such as digital controls, automated cleaning systems, and integration capabilities with other processing equipment can also affect the price. While these features may seem like additional costs, they can enhance productivity and reduce downtime, making them worthwhile investments for many businesses.

Price Ranges and Considerations

When considering the price range for sausage dosing fillers, you can expect to see a wide variety. Basic manual fillers might start as low as a few hundred dollars, while advanced automated models can cost several thousand or even tens of thousands of dollars. It's essential for businesses to assess their production scale, budget, and specific needs before making a purchase.

Conclusion

Investing in a sausage dosing filler is a significant decision that can impact the overall efficiency and quality of meat product production. By considering the various factors influencing pricing—from machine type and brand reputation to customization features and material quality—producers can make informed choices that align with their operational goals. As the demand for quality meat products continues to rise, a reliable and efficient sausage dosing filler can be a game-changer in achieving consistent, high-quality output.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025