Aug . 19, 2024 05:30 Back to list

Sausage Production Equipment for Mincing and Filling in Food Manufacturing Facilities

The Evolution of Sausage Filler and Mincer Factories

Sausage filler and mincer factories play a crucial role in the meat processing industry, transforming raw meat into delicious sausages that are consumed worldwide. The evolution of these factories reflects advances in technology, shifts in consumer preferences, and a growing emphasis on food safety and sustainability.

Historically, sausage making was a manual process. Skilled craftsmen would hand-chop meat and mix it with spices and herbs before stuffing it into casings made from animal intestines. This artisanal approach produced high-quality sausages but was labor-intensive and time-consuming. As demand for processed meats grew in the 19th and 20th centuries, the need for more efficient production methods became apparent. This led to the establishment of sausage filler and mincer factories, where machinery would revolutionize the way sausages were produced.

The Evolution of Sausage Filler and Mincer Factories

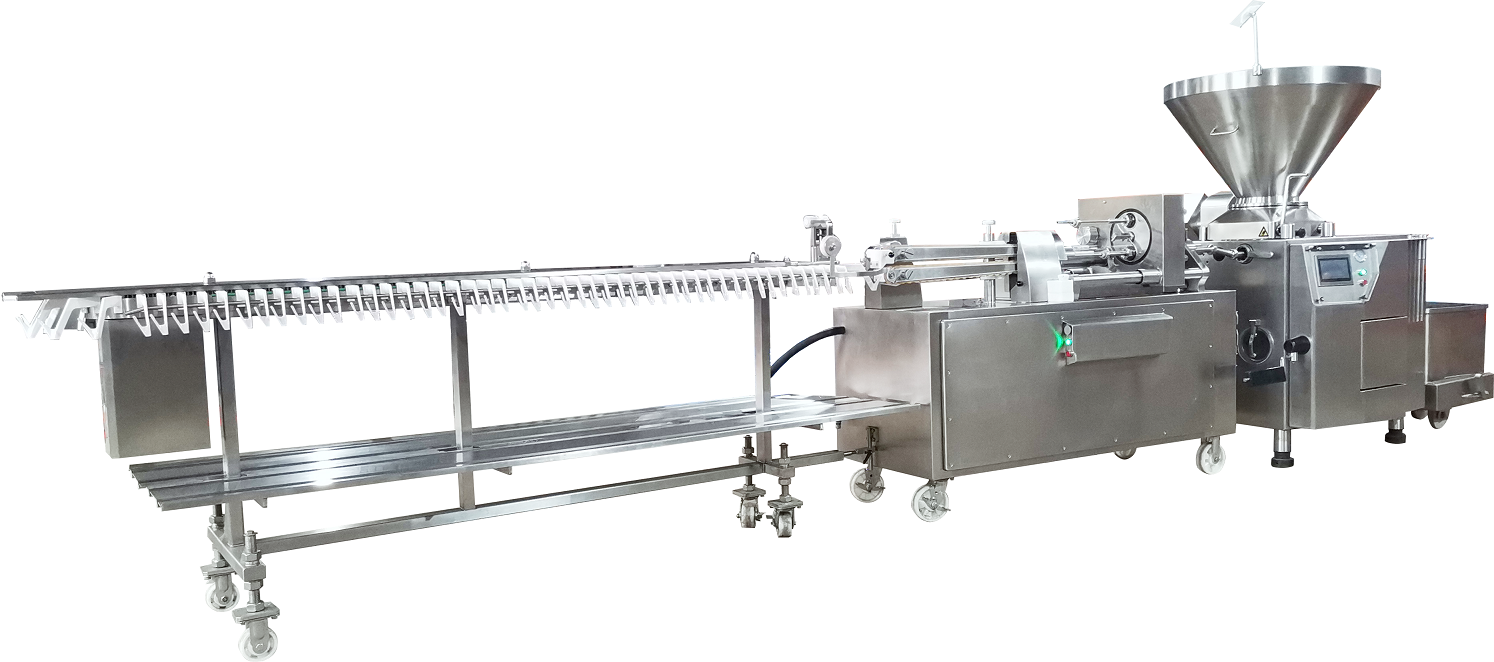

Sausage fillers, designed to stuff casings with minced meat, also underwent remarkable innovations. Early models were purely mechanical, requiring physical effort to operate. Today’s sausage fillers are often pneumatic or hydraulic, allowing for precise control over the filling process and significantly reducing the risk of contamination. The modern filler can produce a wide variety of sausage types, ranging from coarse to fine textures, catering to diverse culinary preferences.

sausage filler and mincer factory

In recent years, the sausage filler and mincer industry has adapted to changing consumer demands, including the rising popularity of plant-based alternatives. Many factories have started incorporating flexible production lines capable of handling both meat and plant-based ingredients. This shift not only taps into the growing market for vegetarian and vegan products but also aligns with increasing consumer awareness of health and sustainability issues.

Moreover, the push for food safety has led to stringent regulations and standards in meat processing facilities. Sausage filler and mincer factories are now equipped with advanced hygiene and sanitation systems to ensure compliance with health standards. Technologies such as metal detectors and x-ray machines are utilized to detect contaminants, providing an additional layer of safety for consumers.

The growing emphasis on sustainability is another significant trend influencing the sausage filler and mincer industry. Many factories are striving to minimize waste and use ethically sourced ingredients. Some have adopted zero-waste practices, transforming by-products from sausage production into other products, such as pet food or organic fertilizer. This commitment to sustainability resonates with consumers looking for environmentally friendly options in their food choices.

As the sausage filler and mincer industry continues to evolve, it remains focused on innovation, quality, and consumer satisfaction. The future holds exciting prospects, including the integration of smart technology for enhanced efficiency and transparency in production processes. With the rise of digital platforms, consumers can now trace their food from farm to table, gaining insights into how their favorite sausages are made.

In conclusion, sausage filler and mincer factories are at the forefront of a dynamic industry that has adapted over the decades to meet changing tastes and standards. As technology advances and consumer preferences evolve, these factories will continue to play a vital role in delivering quality meat products to consumers, ensuring that tradition and innovation coexist in the world of sausage making.