Jul . 26, 2024 21:15 Back to list

Top Manufacturers of Meat Bowl Choppers for Efficient Food Processing Solutions and Kitchen Equipment

The Role of Meat Bowl Chopper Manufacturers in the Food Industry

In the food processing industry, the efficiency and quality of meat processing play a crucial role in the overall success of food production. One of the vital pieces of equipment that contribute to this efficiency is the meat bowl chopper. The meat bowl chopper's primary function is to chop, grind, and mix meat products, which is essential for producing numerous food items ranging from sausages to deli meats. Behind every effective meat bowl chopper is a dedicated manufacturer, striving to innovate and improve what they offer.

Understanding Meat Bowl Choppers

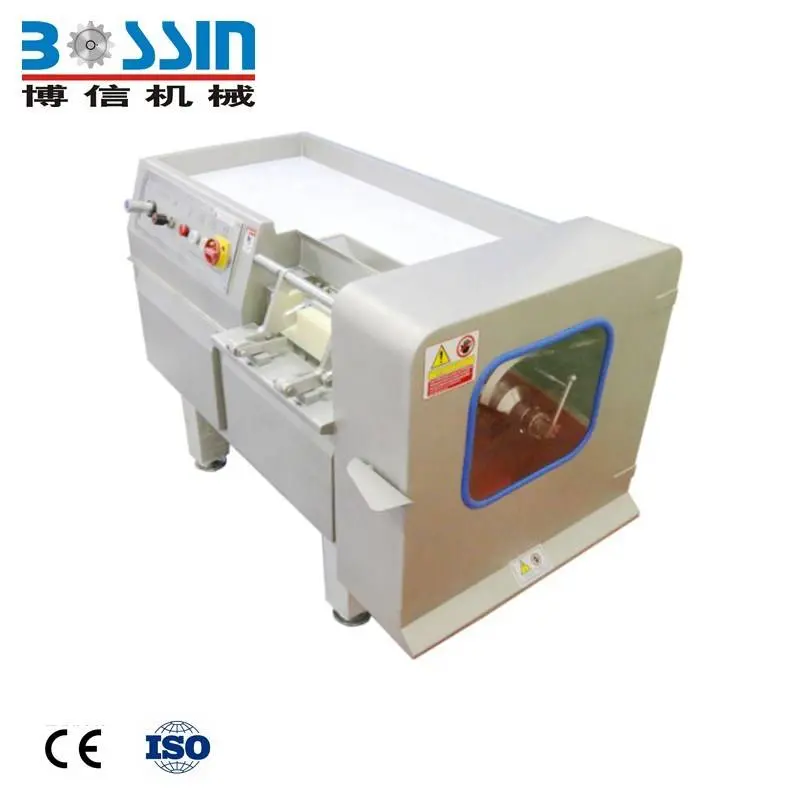

Meat bowl choppers are specialized machines designed to handle various meat types and their respective processing requirements. They typically consist of a bowl that holds the meat and blades that rotate to chop and mix it. The performance of these machines can significantly influence the texture and quality of the finished product, highlighting the importance of choosing the right manufacturer.

The Importance of Quality Manufacturing

Given the critical role meat bowl choppers play in the food processing chain, manufacturers must adhere to strict quality standards. Reputable meat bowl chopper manufacturers invest in high-quality materials and advanced technology to ensure the durability and efficiency of their machines. Stainless steel is commonly used in construction due to its resistance to corrosion and ease of cleaning, both of which are vital in a food processing environment.

Moreover, advanced features such as programmable controls, variable speeds, and specific blade designs contribute to achieving the desired consistency and texture in meat products. Manufacturers continuously innovate, adapting to trends such as the demand for alternative proteins and plant-based meat products. This evolution requires manufacturers to be proactive in developing equipment that can handle different materials and processing techniques.

Safety and Compliance

meat bowl chopper manufacturers

Safety is paramount in the food processing industry, and meat bowl chopper manufacturers prioritize compliance with industry regulations. They must ensure that their machines meet local and international safety standards to minimize risks in food handling and processing. This may include features like safety locks, emergency stop buttons, and easy-clean designs to prevent cross-contamination.

Furthermore, manufacturers often provide extensive training for their customers on the proper use and maintenance of meat bowl choppers. This training helps to ensure that end-users can operate the machines safely and efficiently, ultimately leading to better products.

Custom Solutions and Support

Each processing facility has unique needs based on its size, production volume, and specific meat products. Herein lies the advantage of working with established meat bowl chopper manufacturers that offer custom solutions tailored to meet these distinct requirements. Whether it involves modifying an existing design or developing a completely new machine, manufacturers are willing to collaborate closely with their clients to provide the best possible outcome.

Beyond equipment manufacturing, many companies also offer ongoing support, parts replacement, and maintenance services. This comprehensive approach helps clients maximize the longevity and efficiency of their meat bowl choppers, contributing to sustained productivity and profitability.

Conclusion

In essence, meat bowl chopper manufacturers play a pivotal role in the food processing industry, ensuring that quality equipment is available for effective meat processing. Through dedication to quality, safety, innovation, and customer support, these manufacturers help food processors enhance their operations and deliver high-quality products to consumers. As the industry continues to evolve with consumer demands—such as an increased focus on sustainability and dietary preferences—the role of these manufacturers will only become more significant in shaping the future of food production. By investing in reliable meat bowl choppers, processors can ensure they remain competitive in a fast-paced market.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025