jan . 26, 2025 08:59 Back to list

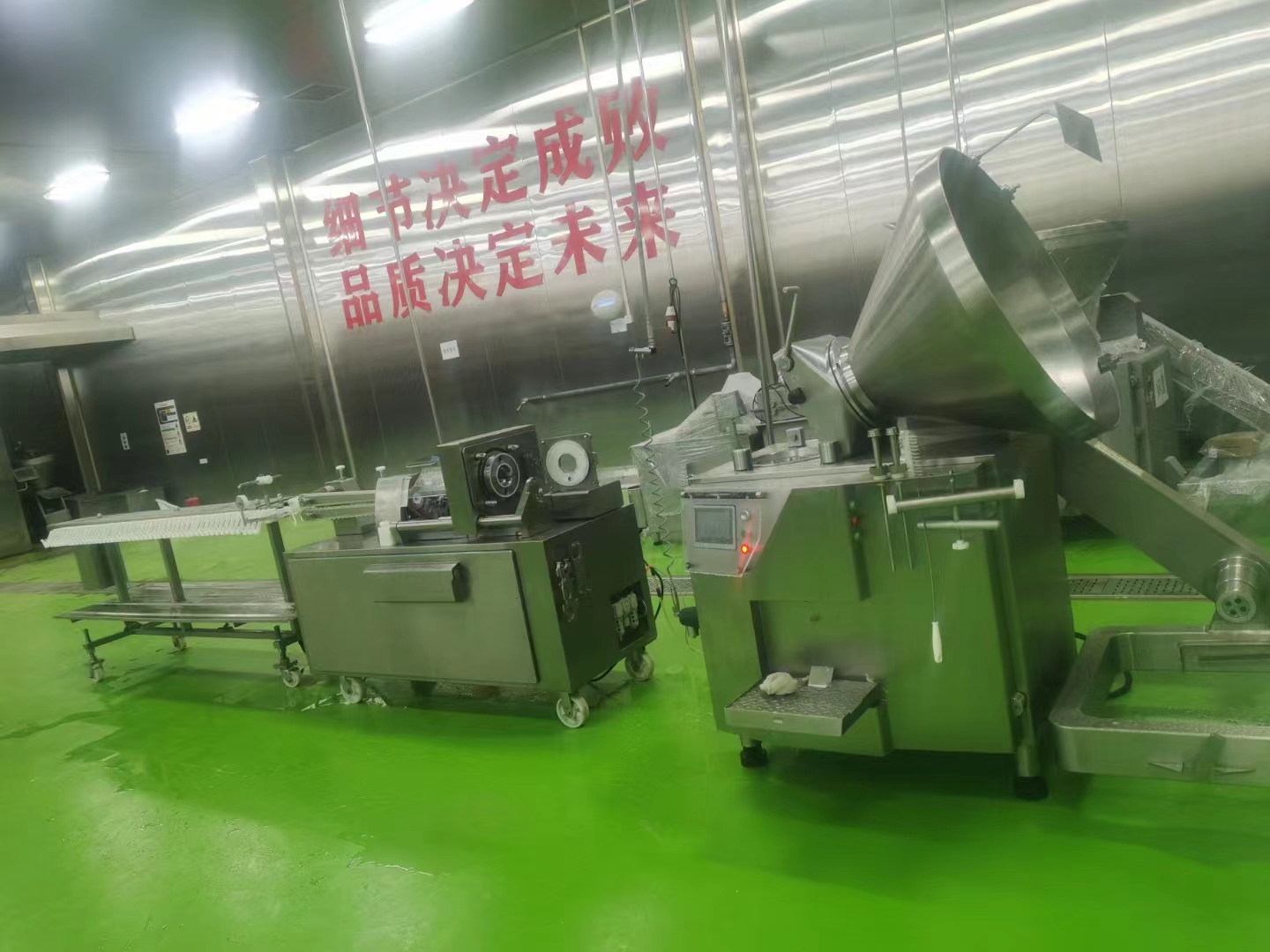

Sausage clipper machine

A vacuum bowl cutter stands at the forefront of culinary technology, an indispensable appliance in both commercial kitchens and meat processing plants. Its primary purpose is the transformation of raw meat into finely chopped or emulsified products like sausages, pâtés, and other delicatessen goods. The innovation behind vacuum bowl cutters lies in their unique ability to operate under vacuum conditions, yielding superior texture and product longevity.

The trustworthiness of vacuum bowl cutters is evidenced by their robust construction and consistent performance. These machines are typically made from high-grade stainless steel, ensuring both durability and hygiene, critical factors in food safety and longevity. Reputable brands provide extensive warranties and comprehensive after-sales support, reflecting their confidence in the product's reliability. Moreover, safety features such as emergency stop functions and secure lid locking mechanisms are standard, ensuring the well-being of operators. In a competitive market, acquiring a vacuum bowl cutter represents an investment in quality and efficiency. Increased efficiency through reduced operating times coupled with improved product yield results in a favorable return on investment for many businesses. This makes vacuum bowl cutters not only a tool for enhancing product quality but also a strategic component in cost management for professional kitchens and meat processing facilities. Ultimately, incorporating a vacuum bowl cutter into your food processing toolkit harnesses the power of modern technology to fulfill ancient culinary arts. Whether you are crafting gourmet sausages or perfecting a batch of liver pâté, a vacuum bowl cutter grants the professional edge necessary to stand out in the food industry. Its blend of innovation, reliability, and quality underscores a commitment to excellence that aligns with the highest standards of culinary craftsmanship.

The trustworthiness of vacuum bowl cutters is evidenced by their robust construction and consistent performance. These machines are typically made from high-grade stainless steel, ensuring both durability and hygiene, critical factors in food safety and longevity. Reputable brands provide extensive warranties and comprehensive after-sales support, reflecting their confidence in the product's reliability. Moreover, safety features such as emergency stop functions and secure lid locking mechanisms are standard, ensuring the well-being of operators. In a competitive market, acquiring a vacuum bowl cutter represents an investment in quality and efficiency. Increased efficiency through reduced operating times coupled with improved product yield results in a favorable return on investment for many businesses. This makes vacuum bowl cutters not only a tool for enhancing product quality but also a strategic component in cost management for professional kitchens and meat processing facilities. Ultimately, incorporating a vacuum bowl cutter into your food processing toolkit harnesses the power of modern technology to fulfill ancient culinary arts. Whether you are crafting gourmet sausages or perfecting a batch of liver pâté, a vacuum bowl cutter grants the professional edge necessary to stand out in the food industry. Its blend of innovation, reliability, and quality underscores a commitment to excellence that aligns with the highest standards of culinary craftsmanship.

Next:

Latest news

-

Pneumatic Clipping Machine: Automated Sausage Production Solution | Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Automated Clipping, Hygienic Design

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping

NewsAug.08,2025

-

Fast & Efficient Frozen Meat Block Flaker Machine

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Efficiency&Hygiene

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|sausage production line,pneumatic technology

NewsAug.07,2025