ਨਵੰ. . 03, 2024 10:06 Back to list

vacuum rapid automatic electric sausage filler factories

The Rise of Vacuum Rapid Automatic Electric Sausage Fillers

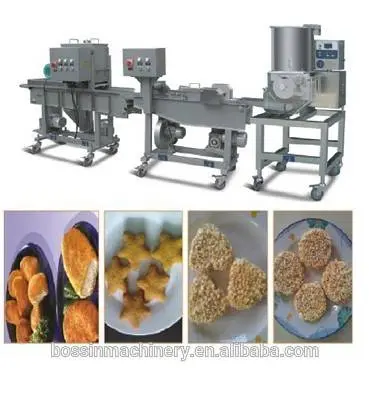

In the fast-paced world of food production, the demand for efficiency and quality has driven innovation in the meat processing industry. One of the most significant advancements is the development of vacuum rapid automatic electric sausage fillers. These machines are revolutionizing the way sausages are produced, providing factories with the ability to enhance their output while maintaining high standards of quality.

Vacuum sausage fillers utilize advanced technology to minimize air incorporation during the filling process. By creating a vacuum environment, these machines ensure that the sausage mixture remains dense and free from air pockets, which can lead to spoilage and affect texture. This technology is crucial for extending the shelf life of sausages and improving overall product quality. The result is a consistently superior product that meets both consumer expectations and regulatory standards.

Automatic electric sausage fillers are designed for high-speed production, significantly increasing the output of sausage factories. Traditional manual filling methods can be time-consuming and labor-intensive, leading to inefficiencies and higher operational costs. In contrast, automated fillers streamline the process, allowing for continuous production without the need for constant human oversight. This automation not only enhances productivity but also reduces labor costs, allowing factories to allocate resources more effectively.

vacuum rapid automatic electric sausage filler factories

Moreover, modern vacuum sausage fillers often come equipped with state-of-the-art controls and monitoring systems. These features enable precise adjustment of filling speeds, portion sizes, and even flavors, catering to the specific needs of different markets. Factories can easily switch between various sausage recipes, ensuring versatility in production without compromising quality.

The environmental impact of sausage production is another important consideration. Many advanced vacuum fillers are designed with energy efficiency in mind, minimizing waste and reducing the carbon footprint of manufacturing processes. This aligns with the increasing consumer demand for sustainable and responsibly sourced food products.

In summary, the introduction of vacuum rapid automatic electric sausage fillers represents a significant leap forward in the meat processing industry. By combining technology with efficiency, these machines enable factories to produce high-quality sausages at an unprecedented pace. As the industry continues to evolve, the role of automation and innovative machinery will be essential in meeting the challenges of modern food production while delighting consumers worldwide.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025