Dec . 11, 2024 10:24 Back to list

Top Manufacturers of Sausage Double Clipper Machines and Equipment Solutions

The Sausage Double Clipper A Game Changer in Food Processing

In the world of meat processing, efficiency and precision are key to satisfying both consumer demand and ensuring product quality. One essential tool that has gained prominence in this industry is the sausage double clipper. This equipment is integral to the manufacturing of sausages, not only enhancing productivity but also improving the overall quality of the final product. In this article, we will explore the importance of sausage double clippers, their benefits, and notable manufacturers in the market.

What is a Sausage Double Clipper?

A sausage double clipper is a specialized machine used in the sausage production process to securely clip the ends of sausage casings after they have been filled with meat or other ingredients. Typically, this device utilizes two clips at once, which allows for faster and more efficient sealing compared to machines that use a single clip. By applying two clips simultaneously, manufacturers can greatly increase their output while maintaining high-quality standards.

Benefits of Using Sausage Double Clippers

1. Increased Production Speed The primary advantage of a sausage double clipper is its ability to speed up the packaging process. By functioning at a higher throughput, manufacturers can produce more sausages in less time, ultimately increasing the efficiency of production lines.

2. Consistency With precise clipping mechanisms, sausage double clippers ensure that each sausage is uniformly sealed. This consistency is vital for customer satisfaction, as it not only affects the aesthetics of the product but also its freshness and shelf life.

3. Reduced Labor Costs Automating the clipping process reduces the dependence on manual labor. This not only lowers labor costs but also minimizes human error, leading to fewer defective products and waste.

4. Versatility Many modern double clippers come with adjustable features, allowing them to work with different sizes and types of casings. This versatility enables manufacturers to produce a wider range of sausage products, catering to varied market demands.

5. Improved Food Safety By providing a secure seal, sausage double clippers help to prevent contamination and spoilage. This is crucial in the food industry, where maintaining hygiene standards is of utmost importance.

Innovations in Sausage Double Clipper Technology

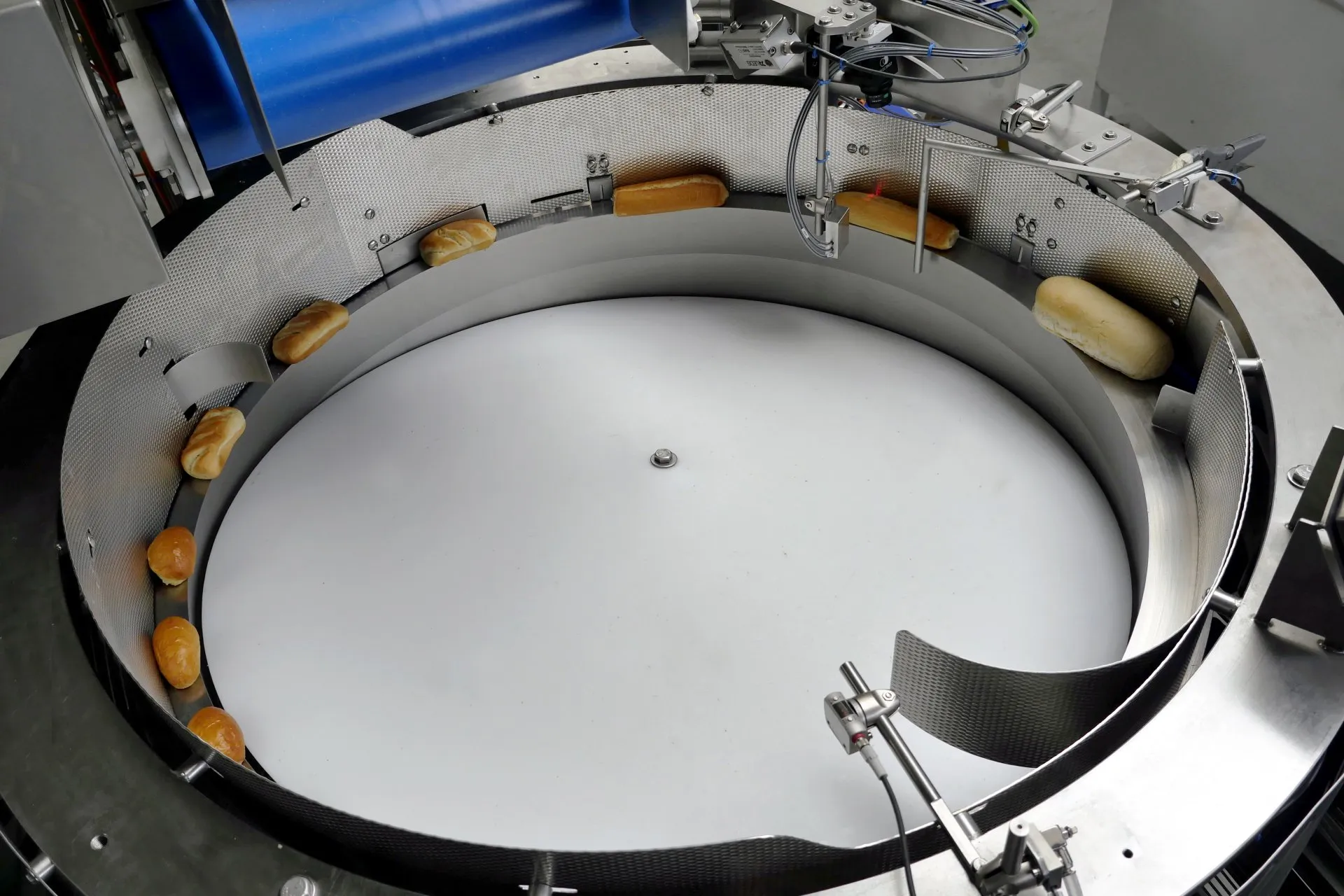

sausage double clipper manufacturers

As with many food processing technologies, innovations have transformed the design and functionality of sausage double clippers. Many current models are equipped with advanced technology such as touch-screen interfaces, automated calibration systems, and real-time monitoring capabilities. These features allow operators to adjust settings quickly and efficiently, ensuring optimal performance and reducing downtime.

Additionally, manufacturers have begun incorporating eco-friendly materials and processes into their machines. For instance, some clippers now utilize biodegradable clips that reduce the overall environmental impact of the food processing operation.

Leading Manufacturers of Sausage Double Clippers

Several manufacturers are known for their high-quality sausage double clippers, each bringing unique features and innovations to the market. Here are a few notable names

1. Bizerba Renowned for its precision and innovative design, Bizerba offers a range of sausage double clippers that focus on efficiency and user-friendliness.

2. Vemag This company provides robust machines that integrate seamlessly into existing processing lines, known for their durability and reliability.

3. Handtmann With a focus on high-performance equipment, Handtmann is a leader in the field, offering technologically advanced double clippers capable of handling multi-layered products.

4. Wolfking Wolfking is recognized for its commitment to quality and efficiency, producing machines that are adaptable to various production needs.

Conclusion

Sausage double clippers are an indispensable part of modern sausage production, delivering significant advantages in speed, consistency, and food safety. As technology advances, these machines continue to evolve, offering even more options for manufacturers looking to enhance their output and product quality. With a range of trusted manufacturers leading the charge, the future of sausage production looks promising, enabling businesses to meet the ever-growing consumer demand for high-quality meat products. As a critical component of the food processing industry, sausage double clippers will undoubtedly play a pivotal role in shaping the future of sausage manufacturing.

Latest news

-

Great Wall DKJC Series Auto Sausage Clipper: Efficient & Durable

NewsJul.25,2025

-

Pneumatic Clipping Machine: Efficient and Reliable Solution for Industrial Applications|Precision Cutting, Durability

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Cutting, High-Speed Operations

NewsJul.21,2025