Dec . 17, 2024 22:11 Back to list

Electrical Meat Grinder Manufacturers and Their Production Processes for High-Quality Products

The Rise of Electric Meat Mincer Factories Revolutionizing Food Processing

In recent years, the food processing industry has undergone a significant transformation, particularly with the introduction of advanced technology in the production of meat mincers. Electric meat mincer factories are at the forefront of this revolution, providing efficient, reliable, and hygienic solutions for both large-scale commercial operations and small-scale domestic users. This article delves into the evolution of electric meat mincers, the benefits of electric factories, and their impact on the food industry.

Historical Context

The history of meat mincing can be traced back to the 19th century when manual mincers were widely used. These devices were labor-intensive and required considerable effort to operate. The advent of electric motors in the early 20th century marked a turning point in food processing technology. Electric meat mincers allowed for faster and more efficient meat processing, enabling butchers and restaurants to serve their customers quickly. Over time, the design and functionality of these machines evolved, leading to the sophisticated electric meat mincers we see today.

The Modern Electric Meat Mincer Factory

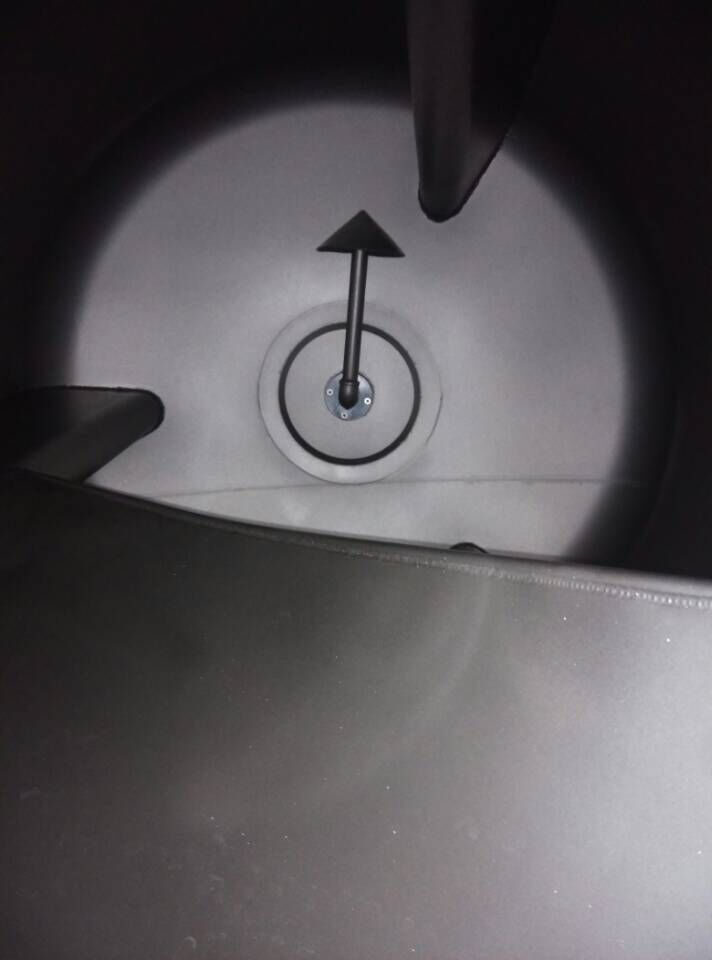

Today, electric meat mincer factories are equipped with cutting-edge technology and automated processes that streamline production. These factories utilize advanced machinery, robotics, and specialized software to manufacture a range of electric meat mincers. The production process typically involves several stages, including metal fabrication, assembly, quality control, and packaging.

One of the most significant advancements in modern electric meat mincer factories is the use of stainless steel and other durable materials that ensure hygiene and durability. Cleanliness is paramount in food processing, and these factories adhere to strict health and safety regulations to produce machines that meet industry standards.

Benefits of Electric Meat Mincer Factories

1. Efficiency Electric meat mincers can process large quantities of meat in a short amount of time compared to manual methods. The high-speed operation of these machines significantly reduces labor costs and increases productivity in commercial kitchens and meat processing plants.

meat mincer electrical factories

2. Consistency One of the challenges of manual mincing is the inconsistency in the final product. Electric meat mincers ensure uniformity in size and texture, resulting in high-quality ground meat that meets consumer expectations.

3. Safety Modern electric meat mincers are equipped with safety features that protect operators from accidents and injuries. Moreover, the hygienic design of these machines minimizes the risk of contamination, a crucial factor in food safety.

4. User-Friendliness Electric mincers are designed to be easy to use, often featuring simple controls and ergonomic designs that make them accessible to a wide range of users, from home cooks to professional chefs.

5. Versatility Many electric meat mincers come with various attachments and settings that allow users to not only grind meat but also prepare sausages, pasta, and other food products, making them multifunctional kitchen tools.

Impact on the Food Industry

The emergence of electric meat mincer factories has had a profound impact on the food industry. With the ability to produce high-quality minced meat quickly and efficiently, these factories support the growing demand for convenience foods and ready-to-cook meals. As consumers increasingly seek quality and convenience, the role of electric meat mincers has become indispensable in the supply chain.

Furthermore, electric meat mincer factories contribute to sustainability efforts by enabling better use of meat products and reducing waste. By offering various grinding options, these machines allow businesses to utilize different cuts of meat effectively, minimizing the environmental impact of food production.

Conclusion

Electric meat mincer factories are transforming the meat processing landscape, bringing about unprecedented efficiency, safety, and product quality. As technology continues to advance, we can expect further innovations in this industry, leading to even better solutions for consumers and businesses alike. The rise of electric meat mincers signifies not only an evolution in food processing but also a commitment to providing safer, more reliable, and higher-quality meat products for all.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025