vacuum mixer

1. Application

Excellent for use in meat processing factories, butcheries, delicatessen, dairy products, ready meals food processing factories and all the food producers those need to mix raw material very quickly lots of different products.

Vacuum mixer, the meat and spices under the vacuum state,Which can improve the retention of the color ,smell and taste ,reduce the time of the next processing and ensure longer shelf life .

Materials are mixed and agitated by double shaft fan-shape propeller after materials have been expanded under the pressure. The meat and additives materials will be mixed sufficiently

(standard machine)

2. Standard equipment

2.1 Qaab dhismeedka: Vakuum Mixer wuxuu ka kooban yahay jir, foosto isku qasan iyo sanduuq koronto ah. Waxay qabataa SUS304 birta aan fiicnayn, waxay buuxisaa shuruudaha caafimaadka qaba ee HACCP.

2.2 Xakamaynta: Control panel with function keys or PLC control(optional, tailor made).

2.3 Tilmaam:

2.3.1 Two kinds of paddle shape, Special paddle structure achieves an efficient and energetic mixing without any damage to the products, all the stuffing are pushed through the Spiral boost devices which ensure uniform mixing results. Double paddles improve mixing effect and working efficiency. Under Vacuum state, products was mixed sufficiently and agitated by two paddles.Forwarding rotation is for mixing;Reverse rotation is for output

PADDDEL MIXING SHAFT(Standard)

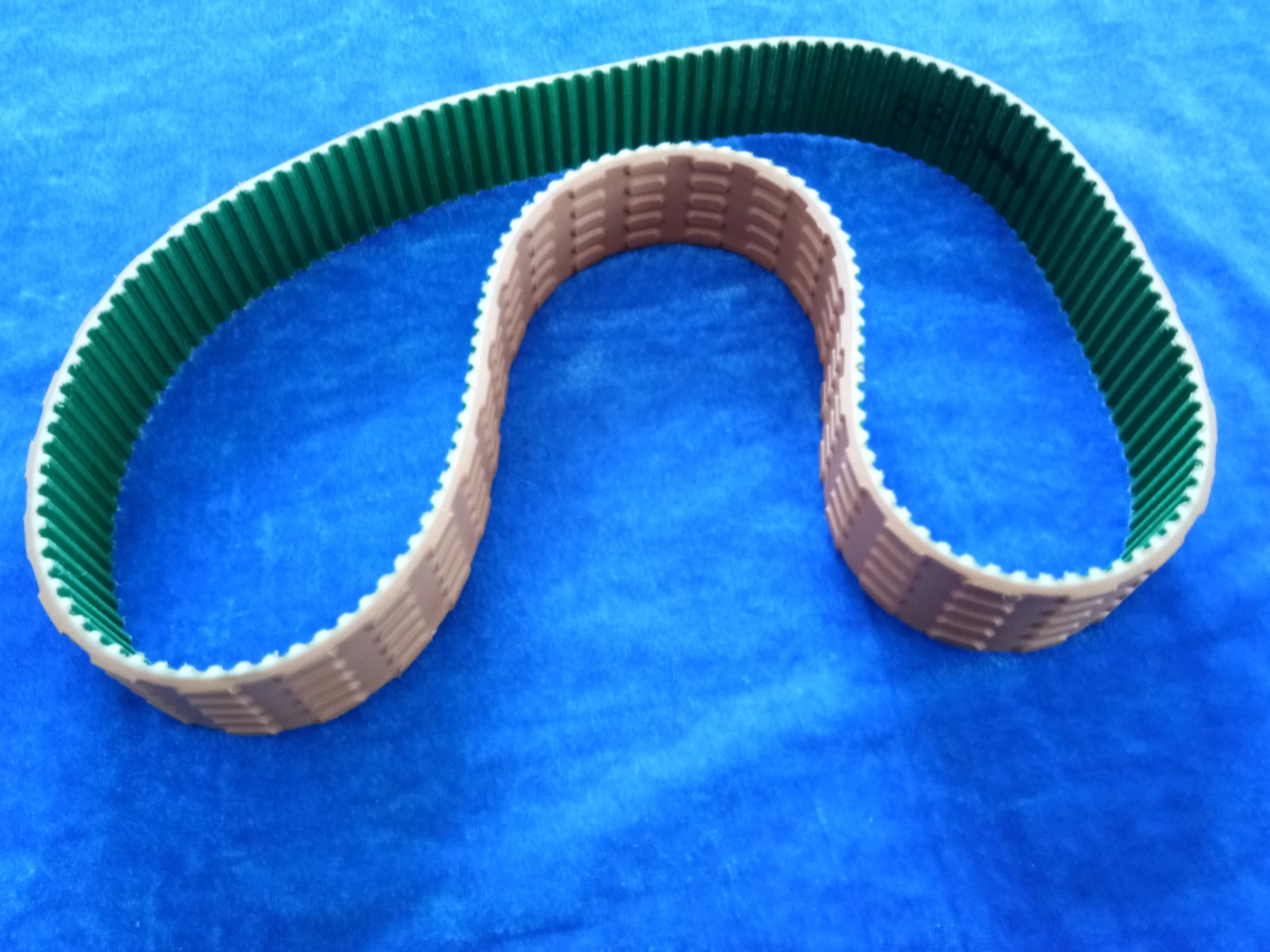

PADDLE + RIBBON MIXING SHAFT(optional)

2.3.2 Computerized auto control. 99 recipes could be restored. Temperature display is available. This function is for PLC controlled, touch screen operation. (optional,tailor made)

2.3.3 The cover and output are controlled air power, so the customer will prepare the air compressor by them self. Below output , it can place one or two 200L meat trolley.

2.3.4 Durable, stable and compact construction guarantees a long production life for the mixer. Silent work of machine.

3. Technical data

|

Nooca |

Cabirka Dibadda mm |

Awood kw |

Mugga L |

Awood kg |

Miisaanka kg |

Vacuum Mpa |

|

ZJB50 |

740×796×775 |

1.11 |

50 |

20 |

208 |

-0.09 |

|

ZJB150 |

1200×700×1260 |

2.75 |

150 |

120 |

384 |

-0.09 |

|

ZJB300 |

1500×1000×1500 |

5.5 |

300 |

240 |

750 |

-0.09 |

|

ZJB650 |

1600×1300×1600 |

7.1 |

650 |

500 |

1070 |

-0.09 |

|

ZJB1200 |

1985*1975*1915 |

13.2 |

1200 |

900 |

1200 |

-0.09 |

JB MIXER WITHOUT VACUUM (optional cover and manual output door)

|

Nooca |

Cabirka Dibadda mm |

Awood kw |

Mugga L |

Awood kg |

Miisaanka kg |

|

JB50 |

740*810*775 |

0.74 |

50 |

20 |

180 |

|

JB150 |

1200×682×1060 |

2.2 |

150 |

120 |

350 |

|

JB300 |

1500×800×1300 |

4.4 |

300 |

240 |

476 |

|

JB650 |

1600×1100×1400 |

6 |

650 |

500 |

731 |

|

JB1200 |

1930×1490×1700 |

11 |

1200 |

900 |

810 |