сеп . 22, 2024 08:20 Back to list

tumbler machine meat material pricelist

Understanding the Pricing of Tumbler Machines for Meat Processing

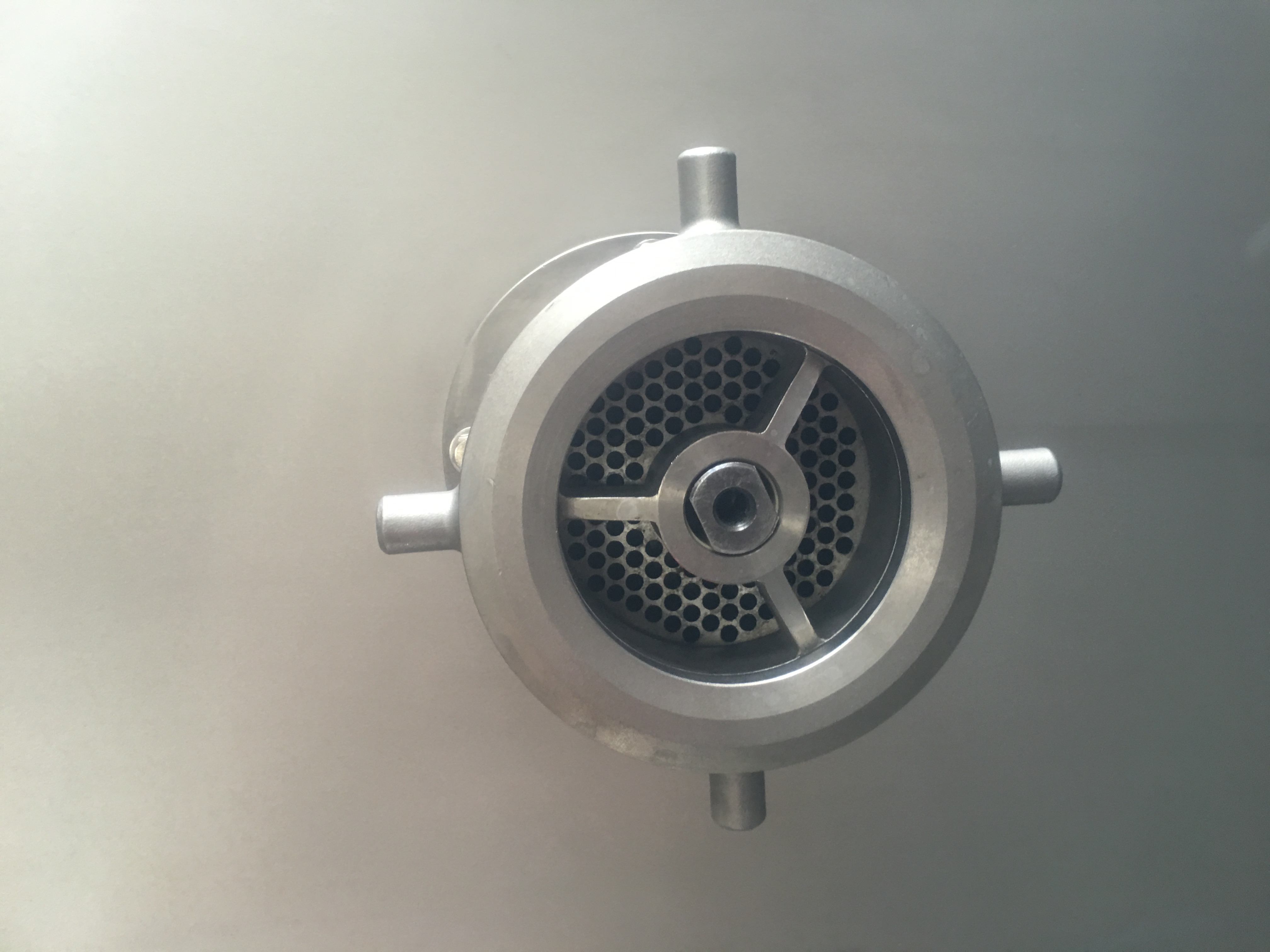

In the meat processing industry, efficiency and quality are paramount. One of the essential tools in this sector is the tumbler machine, used for marinating, flavoring, and tenderizing various meats. As companies strive to maximize flavor and optimize their production processes, understanding the pricing and materials used in tumbler machines becomes crucial.

Tumbler machines are designed to tumble meat, allowing marinades and brines to penetrate the muscle fibers more effectively. This results in enhanced flavor, improved texture, and ultimately a higher quality product. The price of these machines can vary significantly based on several factors, including the materials used in their construction, capacity, and additional features.

Material Considerations

The material of the tumbler machine plays a vital role in its overall cost. Stainless steel is the preferred choice for many manufacturers due to its durability, resistance to corrosion, and ease of cleaning. Machines made from high-quality stainless steel tend to be more expensive, but they provide superior longevity and hygiene standards, making them a worthwhile investment for businesses focused on quality.

Conversely, machines constructed from lower-grade metals can be less expensive, but they may not withstand the rigorous demands of a busy processing environment. It is essential for buyers to consider the long-term costs associated with cheaper materials, which may include more frequent repairs or replacements.

tumbler machine meat material pricelist

Capacity and Features

The capacity of a tumbler machine is another significant factor influencing its price. Smaller units may be more affordable, but they might not meet the demands of larger operations. On the other hand, high-capacity machines can be more expensive, but they offer the advantage of processing larger batches of meat, thereby increasing efficiency and reducing labor costs per unit.

Moreover, additional features such as programmable settings, vacuum tumbling capabilities, and user-friendly interfaces can also impact pricing. Machines equipped with these advanced features tend to be pricier, but they can result in improved consistency and efficiency in meat processing.

Conclusion

When considering the purchase of a tumbler machine, it is essential to assess your specific needs concerning capacity, material, and features. While higher-quality machines may require a larger initial investment, they often lead to better long-term outcomes in terms of both product quality and operational efficiency. Understanding the interplay between these factors and their impact on pricing will allow meat processors to make informed decisions that align with their operational goals and budget constraints. As the industry continues to evolve, investing in the right equipment is more critical than ever for maintaining competitive advantage.

Latest news

-

SG Pneumatic Sausage Filler: Efficient, Reliable Meat Stuffing

NewsAug.11,2025

-

Pneumatic Clipping Machine: Precision & Efficiency for Sausage Production | Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.11,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision Sausage Production, Efficient Operation

NewsAug.11,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production Line,Compressed Air Efficiency

NewsAug.11,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.11,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery|Sausage Production Line,Small Meat Shop,Supermarket

NewsAug.10,2025