Oct . 15, 2024 18:26 Back to list

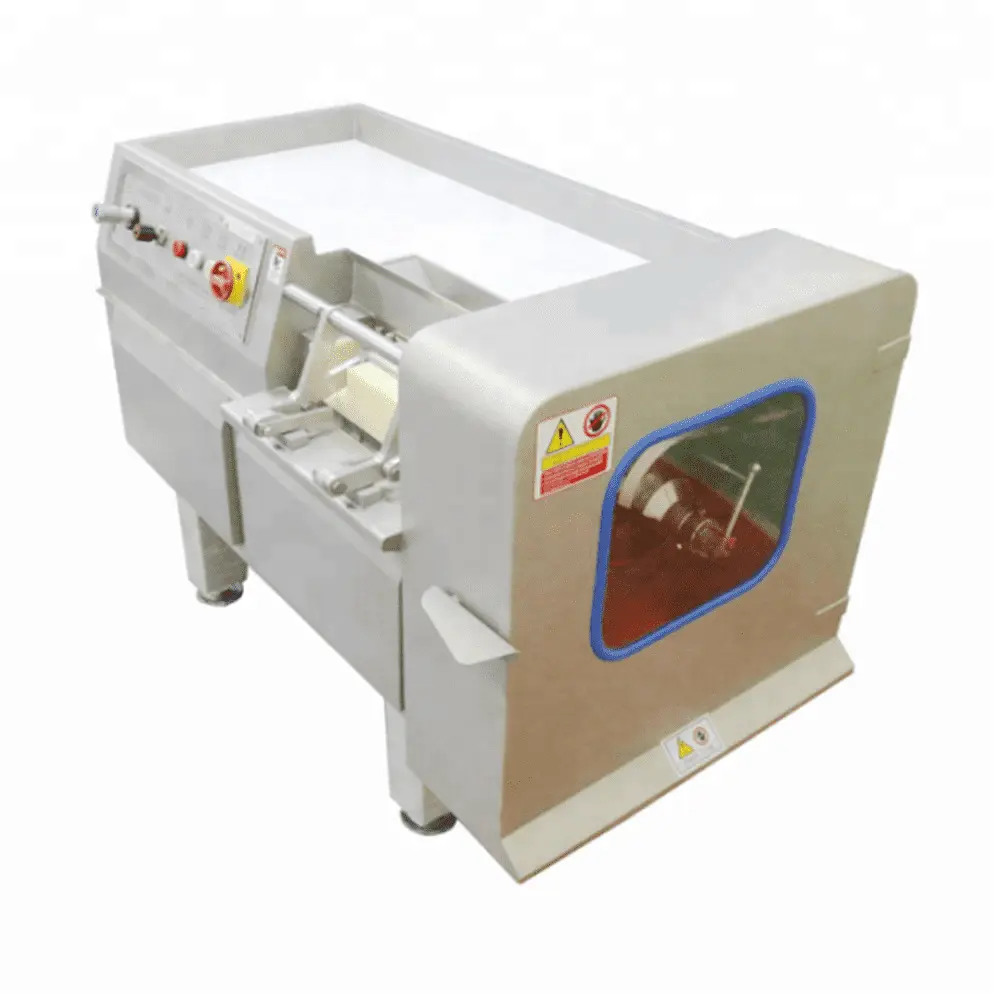

china chicken spearation machine

The China Chicken Separation Machine Revolutionizing Poultry Processing

In recent years, the poultry industry has seen significant advancements in technology, and one of the standout innovations has been the development of the chicken separation machine. Particularly in China, where poultry farming is a major economic sector, these machines are transforming the way chicken processing is conducted, enhancing efficiency and productivity.

The chicken separation machine is designed to streamline the process of separating meat from bones, making it easier for processors to achieve high-quality meat products. Traditional methods of chicken processing often involve manual labor, which can be time-consuming, labor-intensive, and prone to inconsistency. The introduction of automated separation machines addresses these challenges while maintaining the integrity and quality of the meat.

How the Chicken Separation Machine Works

The operation of chicken separation machines is based on advanced technology that utilizes mechanical and sometimes hydraulic systems to efficiently detach meat from poultry carcasses. The machines are capable of handling various chicken parts, including thighs, breasts, and wings, effectively separating the meat in a manner that minimizes waste and maximizes yield.

Equipped with precise sensors and adjustable settings, these machines can operate at differing speeds and accommodate various sizes of chicken parts. This flexibility makes them suitable for both small-scale poultry processors and large industrial operations. By optimizing the separation process, these machines not only save time but also ensure that the meat is processed to stringent hygiene standards.

Benefits of Using Chicken Separation Machines

china chicken spearation machine

1. Increased Efficiency One of the most significant advantages of chicken separation machines is their ability to significantly boost processing efficiency. By automating the separation process, these machines can handle large volumes of chicken in a fraction of the time it would take workers to do so manually.

2. Cost-Effectiveness Although the initial investment in such machinery might be substantial, the long-term savings on labor costs and increased production rates make them economically viable for many poultry facilities. These machines help streamline operations, allowing workers to focus on other essential tasks rather than repetitive separation processes.

3. Improved Meat Quality By utilizing state-of-the-art technology, chicken separation machines can ensure a higher quality of meat by reducing the risk of contamination associated with manual handling. The precision of these machines also helps to extract more meat from carcasses, ensuring that processors get the maximum yield.

4. Workplace Safety Automating the separation process reduces the physical strain on workers and minimizes the risk of injuries commonly associated with manual cutting and handling of poultry. This shift not only protects employees but also contributes to a more efficient working environment.

Conclusion

As the demand for poultry products continues to rise globally, the chicken separation machine represents a significant technological advancement in the processing industry. Particularly in China, where the poultry sector is booming, these machines are essential for meeting the growing needs of consumers while ensuring quality and safety in production. As technology continues to evolve, we can expect further innovations that will enhance efficiency and sustainability in the poultry industry, positioning it for future growth and success. The chicken separation machine stands at the forefront of this transformation, paving the way for a more automated and efficient poultry processing landscape.

Latest news

-

Pneumatic Clipping Machine: Automated Sausage Production Solution | Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Automated Clipping, Hygienic Design

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping

NewsAug.08,2025

-

Fast & Efficient Frozen Meat Block Flaker Machine

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Efficiency&Hygiene

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|sausage production line,pneumatic technology

NewsAug.07,2025