Dec . 11, 2024 12:10 Back to list

sausage packaging machine factories

The Evolution and Importance of Sausage Packaging Machine Factories

In today’s fast-paced world, the meat processing industry has undergone a significant transformation, particularly in the packaging segment. Sausage packaging machine factories play a crucial role in this sector, enhancing efficiency, ensuring product safety, and meeting consumer demands. As the meat industry continues to grow globally, understanding the significance of these factories, their operations, and technological advancements becomes increasingly important.

The Role of Sausage Packaging Machine Factories

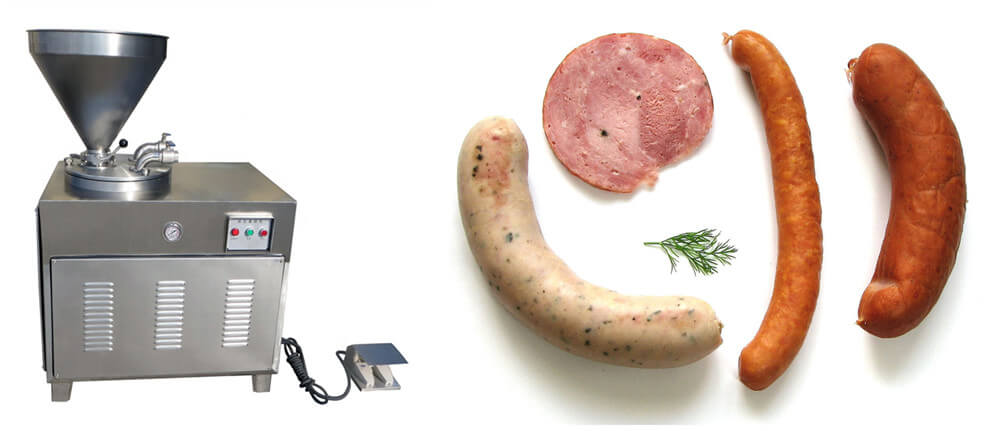

Sausage packaging machine factories specialize in the design and manufacture of machinery that automates the packaging process for various types of sausages. This process encompasses numerous steps, including filling, sealing, labeling, and boxing. The primary goal is to protect the product while extending its shelf life and maintaining its quality. These machines are tailored to accommodate different types of sausages, whether they be fresh, smoked, or ready-to-eat variants.

These factories employ skilled technicians, engineers, and production staff who collaborate to develop innovative machinery solutions. By integrating advanced technologies and automation, they streamline the packaging process, which significantly reduces labor costs and minimizes human error. Moreover, these machines are designed to comply with stringent food safety regulations, ensuring that the packaged sausages are safe for consumer consumption.

Key Features of Modern Sausage Packaging Machines

Modern sausage packaging machines come equipped with a range of features that enhance their efficiency and reliability. One key aspect is the use of high-quality materials that resist contamination and preserve the freshness of the sausage. Additionally, these machines often incorporate vacuum-sealing technology. Vacuum packing removes air from the packaging, dramatically reducing oxidation and bacterial growth, which leads to longer shelf life.

Another innovative feature is the integration of smart technology, such as sensors and advanced control systems. These systems monitor the packaging process in real-time, allowing for adjustments to be made instantly. This not only ensures consistent quality but also minimizes waste due to spoilage or packaging defects.

Moreover, many factories are adopting eco-friendly practices by producing machines that utilize recyclable materials or reduce energy consumption during operation

. As consumer awareness of sustainable practices increases, sausage packaging machine factories play a role in meeting these expectations, aligning production with environmental responsibility.sausage packaging machine factories

The Impact of Globalization on Sausage Packaging

Globalization has significantly influenced the sausage packaging industry. With the rise of international trade and e-commerce, there is an increasing demand for efficient packaging solutions that cater to different markets. Sausage packaging machine factories need to adapt to various regulatory standards and consumer preferences across different regions. This includes offering customization options for packaging sizes, types, and labeling designs to suit local markets.

Additionally, the growing trend of convenience foods has led to a surge in demand for pre-packaged sausages. Consumers today seek products that are not only fresh but also easy to store and prepare. Consequently, manufacturers are challenged to innovate continuously and improve their packaging to meet these evolving consumer behaviors.

Challenges Faced by Sausage Packaging Machine Factories

Despite the advancements and opportunities presented by globalization, sausage packaging machine factories also face numerous challenges. Competition within the industry is fierce, with numerous manufacturers vying for market share. This drives the need for continuous improvement and investment in research and development to create cutting-edge machinery that meets the latest industry standards.

Furthermore, supply chain disruptions, often exacerbated by global events, can impact the availability of raw materials needed for manufacturing machines. As a result, factories must adopt agile strategies to navigate these challenges while maintaining production efficiency.

Conclusion

Sausage packaging machine factories are an integral part of the meat processing industry. By combining technology, innovation, and sustainable practices, these factories ensure that sausages are packaged efficiently and safely for consumers worldwide. As the industry evolves, these factories will continue to play a pivotal role in meeting the demands of a dynamic market while adhering to safety standards and environmental responsibilities. In this ever-changing landscape, the importance of sausage packaging machinery cannot be overstated.

Latest news

-

Great Wall DKJC Series Auto Sausage Clipper: Efficient & Durable

NewsJul.25,2025

-

Pneumatic Clipping Machine: Efficient and Reliable Solution for Industrial Applications|Precision Cutting, Durability

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Cutting, High-Speed Operations

NewsJul.21,2025