Agosti . 07, 2025 04:00 Back to list

Air-Free Vacuum Mixers for Precise & Homogeneous Blending

In an era demanding unparalleled product quality, consistency, and purity, the vacuum mixer has emerged as an indispensable cornerstone across diverse industrial sectors. From pharmaceuticals to food production, cosmetics to advanced materials, the ability to mix under vacuum conditions revolutionizes processing, eliminating critical challenges like aeration, oxidation, and cross-contamination. This comprehensive guide explores the intricate world of vacuum mixer technology, its technical prowess, widespread applications, and the vital considerations for businesses aiming to optimize their production capabilities.

1. The Pivotal Role of Vacuum Mixers in Modern Industry: Trends and Imperatives

The global market for industrial mixing equipment is experiencing robust growth, driven by increasing automation, stringent quality regulations, and the demand for highly specialized products. Within this landscape, the vacuum mixer segment stands out. According to a report by Grand View Research, the global industrial mixers market size was valued at USD 2.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth is significantly fueled by the increasing adoption of advanced mixing technologies like vacuum mixer, particularly in sectors where product integrity is paramount.

Industry trends reveal a clear shift towards mixers that offer enhanced control over process parameters. This includes not only precise temperature and shear force management but also the crucial ability to eliminate unwanted gas inclusions – a primary advantage of vacuum technology. The rising complexity of new material formulations, such as high-viscosity battery slurries, advanced polymers, and sensitive biological compounds, further underscores the necessity of a vacuum mixer. These machines prevent air bubbles, which can lead to product instability, reduced shelf life, compromised aesthetic appeal, and diminished functional performance (e.g., lower battery energy density). Furthermore, the drive for sustainable manufacturing practices pushes for energy-efficient designs and systems that minimize waste, areas where modern vacuum mixer excel.

2. Understanding the Technology: What is a Vacuum Mixer?

At its core, a vacuum mixer is an industrial processing unit designed to blend, disperse, and homogenize various materials under reduced pressure conditions. This vacuum environment serves several critical functions:

- De-aeration (Degassing): Air entrapment during mixing is a common issue, leading to bubbles that can affect product density, stability, appearance, and shelf life. The vacuum draws out these entrapped gases, resulting in a dense, uniform, and stable product.

- Prevention of Oxidation: For oxygen-sensitive materials (e.g., certain chemicals, food products, or pharmaceutical compounds), mixing under vacuum prevents degradation caused by exposure to atmospheric oxygen, preserving product efficacy and quality.

- Enhanced Homogenization: The absence of air bubbles allows for more intimate contact between particles, facilitating superior dispersion and a truly homogeneous mixture, even for highly viscous or difficult-to-wet materials.

- Precise Temperature Control: Vacuum conditions lower the boiling point of liquids, allowing for gentle evaporation and cooling, or conversely, enabling lower-temperature mixing for heat-sensitive ingredients without degradation.

- Sterile Processing: In industries like pharmaceuticals, the enclosed vacuum system reduces the risk of external contamination, making it ideal for sterile or aseptic processing.

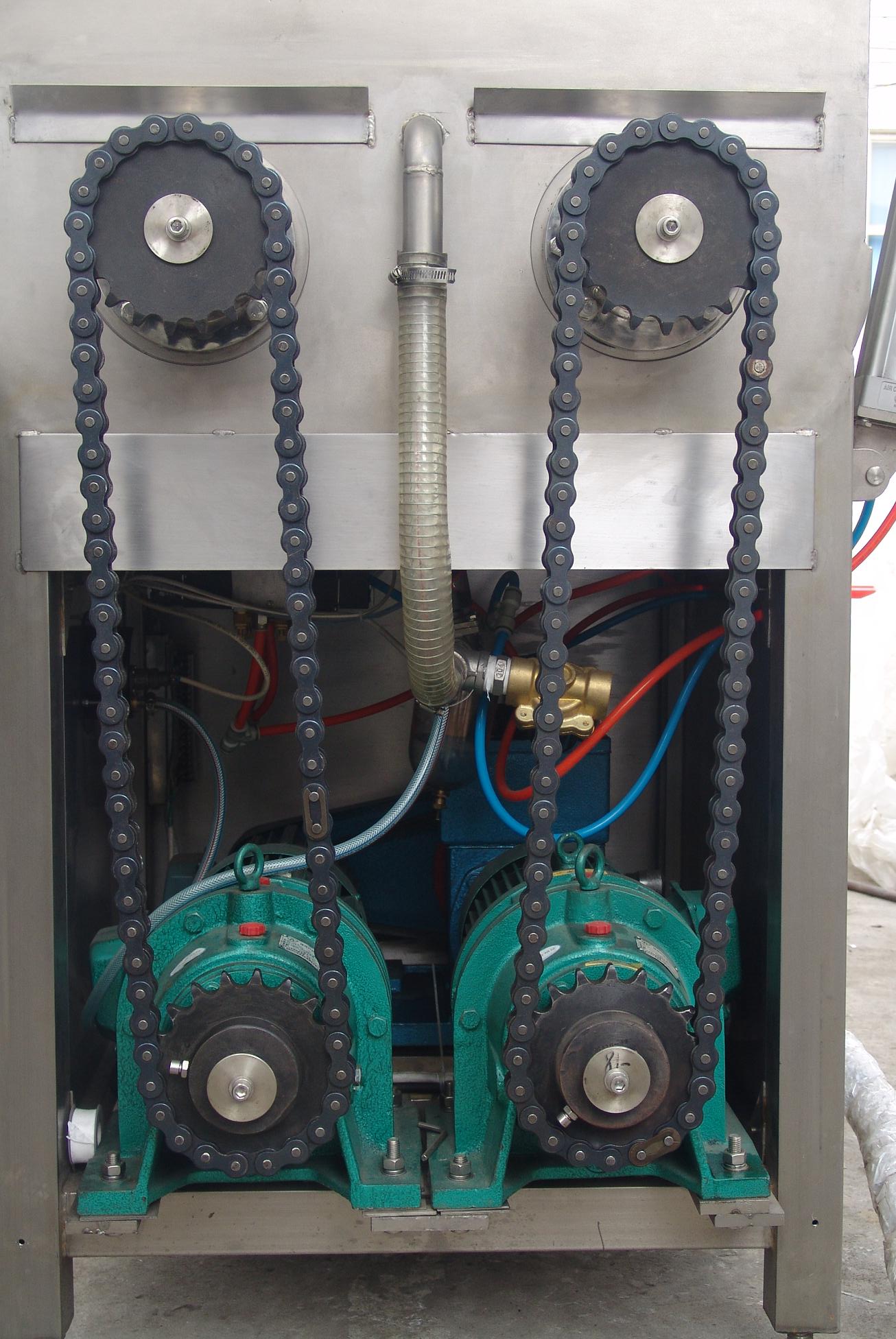

A typical vacuum mixer system comprises a sealed mixing tank (often jacketed for heating/cooling), various agitator types (e.g., anchor, propeller, turbine, high-shear homogenizer), a robust vacuum pump system, an advanced control panel, and ancillary components for ingredient addition and discharge. The choice of agitator and the degree of vacuum applied are critical parameters determined by the specific rheological properties of the material and the desired final product characteristics.

3. Technical Parameters and Specifications of Vacuum Mixers

Understanding the key technical parameters is essential for selecting the right vacuum mixer. These specifications dictate the machine's capacity, performance, and suitability for specific applications.

Typical Vacuum Mixer Specifications

| Parameter | Typical Range / Value | Description |

|---|---|---|

| Capacity | 5L to 10,000L+ | Batch volume, from laboratory scale to large industrial production. |

| Motor Power | 1.5 kW to 75 kW+ | Power of main agitator motor, determining mixing capability for different viscosities. |

| Vacuum Degree | -0.09 MPa to -0.098 MPa (-700 mmHg to -740 mmHg) | Achievable absolute pressure inside the tank, critical for effective de-aeration. Lower values indicate stronger vacuum. |

| Mixing Speed | Main Agitator: 0-60 RPM; High Shear Homogenizer: 0-3600 RPM | Variable speed control for different stages of mixing and material types. |

| Temperature Range | 0°C to 150°C (Heating/Cooling) | Via jacketed vessel, controlled by external utilities (steam, hot water, chilled water). |

| Contact Material | SS304, SS316L, Duplex SS, Hastelloy | Material of parts in contact with product. SS316L is common for sanitary applications. |

| Homogenizer Type | Top-entry, Bottom-entry, External Circulation | Mechanism for fine dispersion and emulsification. |

| Sealing Method | Mechanical Seal, Double Mechanical Seal, Magnetic Drive | Ensures vacuum integrity and prevents leakage, especially for sterile processes. |

| Control System | Manual, Semi-automatic, PLC with HMI | Level of automation and user interface for process control. |

| Cleaning System | CIP (Clean-in-Place), SIP (Sterilize-in-Place) | Automated cleaning and sterilization capabilities crucial for hygienic industries. |

These parameters are crucial for engineering the perfect solution. For instance, a pharmaceutical company producing sterile ointments would require a vacuum mixer with stringent material contact specifications (SS316L with mirror polish), high vacuum capabilities, precise temperature control, and a robust CIP/SIP system to meet GMP (Good Manufacturing Practice) guidelines and FDA (Food and Drug Administration) requirements.

4. The Advanced Manufacturing Process of Vacuum Mixers

The manufacturing of a high-quality vacuum mixer is a testament to precision engineering, robust material science, and adherence to international standards. Bossin Machinery, for instance, emphasizes a meticulous process that guarantees durability, performance, and compliance.

Crafting Excellence: A Step-by-Step Manufacturing Journey

- Material Sourcing and Selection: The process begins with selecting premium-grade materials, primarily stainless steel alloys like SS304 and SS316L (often referred to as 1.4301 and 1.4404 respectively in European standards). For highly corrosive or abrasive applications, duplex stainless steels (e.g., 2205) or exotic alloys like Hastelloy are chosen. All materials are certified with Material Test Reports (MTRs) to ensure chemical composition and mechanical properties meet specifications, crucial for industries like petrochemical and food processing where material integrity is paramount.

- Precision Fabrication & Forming: Stainless steel sheets are cut using advanced laser or plasma cutting technologies to ensure precise dimensions. These sheets are then formed into vessel shells and components using CNC (Computer Numerical Control) bending and rolling machines, minimizing material stress and ensuring accurate geometry. The jacketed design for heating/cooling typically involves a double-wall construction, with channels for fluid circulation.

- Automated Welding Techniques: Welding is a critical phase, especially for vacuum retention and hygienic surfaces. Automated TIG (Tungsten Inert Gas) welding is extensively used, providing clean, strong, and highly corrosion-resistant welds. For critical internal surfaces, orbital welding ensures uniform, smooth bead-free welds, reducing potential areas for bacterial growth. All welds undergo strict inspection, including visual, dye penetrant, and X-ray testing to detect any imperfections, meeting ASME (American Society of Mechanical Engineers) standards for pressure vessels.

- Surface Treatment and Polishing: For hygienic and sterile applications, the internal surfaces of the vacuum mixer are meticulously polished. This typically involves multi-stage mechanical polishing, followed by electro-polishing to achieve a mirror-like finish with a surface roughness (Ra value) as low as 0.2-0.4 µm. This ultra-smooth surface prevents product adhesion, facilitates efficient cleaning (CIP/SIP), and inhibits microbial growth, vital for pharmaceutical and food safety. External surfaces are often satin or matte finished for aesthetics and easy cleaning.

- Precision Machining of Components: Agitators, homogenizers, seals, and connecting flanges are manufactured with high precision using CNC machining centers. This ensures perfect alignment, minimal tolerances, and optimal performance of rotating parts. For instance, mechanical seals are machined to exacting standards to maintain the vacuum integrity during operation and prevent product leakage or ingress of contaminants, contributing to a longer usage life.

- Assembly and Integration: All fabricated and machined components are then meticulously assembled. This involves installing the agitator shafts, homogenizer heads, vacuum pump system, heating/cooling jacket connections, and the control panel. Electrical wiring and pneumatic connections are done according to international safety standards (e.g., CE marking directives).

-

Rigorous Testing and Quality Control: Before shipment, every vacuum mixer undergoes a comprehensive series of tests:

- Hydrostatic Pressure Test: To verify the integrity of the pressure vessel and jacket against leaks.

- Vacuum Leak Test: The entire system is pulled to a deep vacuum, and pressure decay is monitored over time to ensure perfect sealing. This is a crucial test for product integrity.

- Functional Test (FAT/SAT): All motors, agitators, homogenizers, valves, and control systems are run through their operational cycles to confirm functionality and performance as per design specifications. Factory Acceptance Tests (FAT) are often conducted with client representatives present.

- Performance Test: For specific applications, a vacuum mixer might undergo tests with simulated product to verify mixing homogeneity, de-aeration efficiency, and heating/cooling rates.

- Certification and Documentation: Each vacuum mixer is delivered with complete documentation, including operation manuals, maintenance guides, spare parts lists, material certificates, welding reports, and compliance certificates (e.g., ISO 9001:2015 for quality management, CE for European market conformity, and optionally ASME U-stamp for pressure vessels in certain regions). Compliance with GMP (Good Manufacturing Practice) and FDA guidelines is inherently built into the design and manufacturing process for relevant industries.

This exhaustive manufacturing process ensures that a Bossin vacuum mixer offers exceptional durability, reliability, and a long service life, typically exceeding 15-20 years with proper maintenance, even in demanding environments like petrochemical or metallurgical plants requiring robust, anti-corrosion solutions.

5. Diverse Application Scenarios and Industry Advantages of Vacuum Mixers

The versatility of vacuum mixer technology makes it indispensable across a spectrum of industries, each benefiting from its unique capabilities.

Key Application Industries:

-

Pharmaceutical Industry:

Crucial for producing sterile creams, ointments, gels, lotions, vaccines, and suspensions. The vacuum environment ensures de-aeration, preventing oxidation of active pharmaceutical ingredients (APIs) and maintaining product stability and homogeneity. The ability to perform CIP (Clean-in-Place) and SIP (Sterilize-in-Place) is paramount for meeting stringent GMP (Good Manufacturing Practice) and FDA regulations. For example, in vaccine production, a vacuum mixer ensures precise mixing of antigens and adjuvants without air bubbles, which could compromise stability or dosage accuracy.

-

Food & Beverage Industry:

Used for mayonnaise, salad dressings, sauces, purees, baby food, dairy products, and high-viscosity spreads. Vacuum mixing prevents frothing, extends shelf life by removing oxygen, improves texture, and maintains flavor and color. For mayonnaise production, the de-aeration ensures a smooth, stable emulsion free from air pockets that could lead to separation or spoilage. In chocolate processing, a vacuum mixer can refine texture and remove volatiles.

-

Cosmetics & Personal Care:

Essential for manufacturing creams, lotions, shampoos, conditioners, toothpastes, and makeup. The vacuum mixer ensures a smooth, glossy texture, prevents air bubbles that can cause product instability or undesirable appearance, and maintains product consistency. For high-end face creams, achieving a perfectly smooth, bubble-free consistency directly impacts customer perception and product efficacy.

-

Chemical Industry:

Applied in the production of adhesives, sealants, coatings, paints, pigments, resins, and specialized chemical compounds. The vacuum helps in effective dispersion of powders into liquids, prevents solvent evaporation, and ensures uniform mixing of multi-component systems, even for highly viscous or reactive materials. In the production of silicone sealants, the vacuum mixer ensures the complete removal of air, which is critical for curing properties and final product strength.

-

New Materials / Advanced Materials:

Increasingly vital for emerging fields like battery manufacturing (especially for anode and cathode slurries in Li-ion batteries), ceramics, nanomaterials, and composite materials. The precise and bubble-free mixing is crucial for material performance, ensuring uniform distribution of active ingredients and preventing defects. For instance, in battery slurry preparation, achieving a perfectly homogeneous, de-aerated slurry directly impacts the battery's energy density, cycle life, and safety. This requires high shear forces and robust vacuum capabilities.

-

Water Treatment & Metallurgy (P.S. Applicable for related processes):

While not primary applications, specialized vacuum mixer systems find use in processes requiring controlled atmosphere mixing, such as certain chemical additions in water treatment (e.g., flocculants, coagulants) where precise concentration and minimal aeration are desired. In metallurgy, some advanced powder metallurgy processes or specialized alloy preparations might benefit from vacuum mixing to prevent oxidation or entrapment of gases in high-purity metal powders.

Technological Advantages in Typical Application Scenarios:

- Energy Efficiency: Modern vacuum mixer designs incorporate optimized agitator geometries and variable frequency drives (VFDs) for motors. This allows for precise control of mixing speed and power consumption, leading to significant energy savings, particularly during different phases of the mixing process.

- Corrosion Resistance: The use of high-grade stainless steel (SS316L) and specialized alloys ensures the vacuum mixer can withstand highly corrosive ingredients and harsh cleaning agents, extending equipment lifespan and maintaining product purity. This is vital in the petrochemical sector where aggressive chemicals are common.

- Precision and Homogeneity: The combination of powerful agitation under vacuum ensures unparalleled mixing quality. Ingredients are thoroughly dispersed, and the absence of air bubbles allows for a truly uniform product, critical for consistent performance in end-use applications.

- Safety Features: Modern vacuum mixer are equipped with safety interlocks, emergency stops, pressure relief valves, and explosion-proof components (for hazardous environments), ensuring safe operation for personnel and plant.

6. Choosing the Right Supplier: A Comparative Analysis for Vacuum Mixer Solutions

Selecting a vacuum mixer is a significant investment that impacts production efficiency, product quality, and long-term operational costs. It's not just about the machine; it's about the partnership with the manufacturer.

Key Considerations When Comparing Manufacturers:

- Expertise and Experience: A reputable manufacturer like Bossin Machinery will have decades of experience in designing and fabricating industrial mixing equipment. This translates into deep understanding of various industry-specific challenges and the ability to offer proven, reliable solutions. Look for manufacturers with a long track record and a diverse portfolio of successful installations.

- Customization Capabilities: Generic mixers rarely fit all needs. The best suppliers offer extensive customization options, from tank volume and agitator configurations to automation levels (PLC-based control systems, SCADA integration), heating/cooling systems, and specialized material handling. This flexibility ensures the vacuum mixer is perfectly tailored to your specific product rheology and process requirements.

- Quality Standards and Certifications: Adherence to international quality standards (ISO 9001, CE, ASME) is non-negotiable. For pharmaceutical and food industries, GMP, FDA, and 3-A Sanitary Standards compliance are vital. A transparent manufacturer will provide all necessary documentation and allow for factory audits.

-

After-Sales Service and Support: A vacuum mixer is a complex piece of equipment requiring periodic maintenance and potential troubleshooting. Evaluate the manufacturer's commitment to after-sales support, including:

- Installation and Commissioning: Availability of experienced engineers to supervise installation and initial startup.

- Operator Training: Comprehensive training programs to ensure your team can operate and maintain the machine safely and efficiently.

- Spare Parts Availability: Readily available genuine spare parts minimize downtime.

- Technical Support: Responsive technical assistance for troubleshooting and operational queries.

- Technological Innovation: Leading manufacturers continuously invest in R&D to improve mixer efficiency, incorporate advanced automation features, and adapt to new industry demands (e.g., energy recovery systems, enhanced cleaning protocols).

- Total Cost of Ownership (TCO): Beyond the initial purchase price, consider operational costs (energy consumption, maintenance, spare parts) and the expected lifespan of the equipment. A higher initial investment in a well-built vacuum mixer from a reputable vendor often leads to lower TCO due to reduced downtime, lower energy bills, and longer operational life.

7. Tailored Solutions and Real-World Application Case Studies

The true value of a vacuum mixer is often realized through its ability to be customized for specific, unique processing challenges. Bossin Machinery excels in providing bespoke solutions that meet precise client requirements.

Customization Options:

- Agitator Configuration: Choosing from various impeller types (e.g., anchor, frame, propeller, turbine, high-shear rotor-stator homogenizer) and their combinations to achieve optimal shear, flow patterns, and mixing intensity for specific viscosities and particle sizes.

- Heating/Cooling Systems: Integrating jacketed vessels with precise temperature control units (steam, hot water, chilled water, thermal oil) to manage exothermic reactions or maintain product viscosity.

- Load Cell Integration: For highly accurate ingredient dosing and batch weighing, integrating load cells ensures precise formulation control, minimizing waste and ensuring product consistency.

- CIP/SIP Integration: Designing the mixer with spray balls, dedicated cleaning lines, and automated sequencing for effective and repeatable cleaning and sterilization, crucial for hygienic industries.

- Vacuum System Optimization: Tailoring the vacuum pump type and capacity (e.g., liquid ring, dry screw, oil-sealed rotary vane) to achieve the required vacuum level and recovery speed for specific products.

- Automation & Control: From simple push-button controls to advanced PLC-HMI systems with recipe management, data logging, and SCADA integration for remote monitoring and control, enabling Industry 4.0 readiness.

Real-World Application Examples:

Case Study 1: High-Viscosity Battery Slurry Production

A leading battery manufacturer faced challenges in producing highly viscous anode and cathode slurries for lithium-ion batteries. Traditional mixers struggled with achieving homogeneity without entrapping significant air bubbles, which led to defects and reduced battery performance. Bossin Machinery engineered a specialized vacuum mixer system with a powerful dual-shaft design (a planetary mixer for bulk movement and a high-speed disperser for fine particle de-agglomeration) combined with a robust, deep vacuum system. The solution achieved near-zero air inclusion, excellent particle dispersion, and a perfectly homogeneous slurry, resulting in a 15% increase in battery energy density and a 10% reduction in production time due to faster de-aeration cycles.

Case Study 2: Sterile Ointment Production for Pharmaceuticals

A pharmaceutical company required a new mixing solution for a high-volume, sterile dermatological ointment. Key challenges included maintaining sterility, precise temperature control during emulsification, and achieving a smooth, air-free product. Bossin Machinery provided a GMP-compliant vacuum mixer with an SS316L mirror-polished contact surface (Ra ≤ 0.4 µm), integrated CIP/SIP functionality, and a closed-loop vacuum system. The mixer featured a bottom-entry homogenizer for efficient emulsification and an anchor agitator for gentle, thorough blending. The successful implementation led to consistent product quality, significant reduction in batch contamination rates, and full compliance with international regulatory standards (e.g., ISO 13485 for medical device manufacturing where applicable, or GMP for pharmaceuticals).

Case Study 3: Large-Scale Food Emulsion Processing

A major food processor needed to scale up production of a popular creamy sauce, which frequently suffered from frothing and oxidation during traditional mixing, leading to reduced shelf life. A large-capacity vacuum mixer with a top-entry high-shear homogenizer and an anchor scraper was integrated into their production line. The vacuum system effectively eliminated foam, prevented oxidative degradation of fats and flavors, and resulted in a product with superior texture and extended freshness. This led to a 20% increase in product shelf life and a noticeable improvement in consumer satisfaction.

8. Ensuring Trust: Quality Assurance, Delivery, and Customer Support

Building trust with clients is paramount for any reputable manufacturer. Bossin Machinery prioritizes transparency, reliability, and comprehensive support throughout the customer journey.

Quality Assurance:

Our commitment to quality is embedded in every stage of manufacturing. Beyond rigorous internal testing, our vacuum mixer systems comply with international standards such as ISO 9001:2015 for Quality Management Systems, CE certification for European market conformity, and are designed to meet industry-specific regulations like GMP for pharmaceuticals and FDA guidelines for food contact applications. We offer comprehensive Factory Acceptance Tests (FAT) at our facility, where clients can witness the machine's operation and performance firsthand before shipment, ensuring complete satisfaction and verification of specifications.

Delivery and Installation:

We understand the importance of timely project completion. Our typical delivery period for a standard vacuum mixer ranges from 8-12 weeks, depending on customization complexity and production schedule. We provide detailed logistics support, including packaging, shipping coordination, and customs documentation. Upon arrival, our experienced technical team can provide supervision for installation and commissioning, ensuring smooth integration into your existing production line.

Warranty and After-Sales Support:

Every vacuum mixer comes with a standard 12-month warranty from the date of commissioning or 18 months from shipment, whichever comes first, covering manufacturing defects and component failures. Our dedicated after-sales support team is available for remote troubleshooting, and we maintain a comprehensive inventory of genuine spare parts for prompt dispatch, minimizing potential downtime. We offer various support packages, including preventative maintenance contracts and on-site technical visits, to ensure your equipment operates at peak performance throughout its lifespan. Our commitment extends to providing continuous technical advice and assistance to help our clients optimize their mixing processes.

9. Frequently Asked Questions (FAQ) About Vacuum Mixers

Q1: What is the primary benefit of mixing under vacuum compared to atmospheric mixing?

The primary benefit of mixing under vacuum is the effective removal of entrapped air and other volatile gases from the product. This de-aeration process prevents issues like oxidation, frothing, and bubble formation, which can compromise product stability, texture, appearance, and shelf life. For instance, in cosmetic creams, de-aeration ensures a smooth, uniform texture, while in battery slurries, it significantly improves energy density and cycle life.

Q2: What materials are typically used for the contact parts of a vacuum mixer, and why?

The contact parts are typically made from high-grade stainless steel, primarily SS304 (for general applications) or SS316L (for hygienic and corrosive applications). SS316L is preferred due to its superior corrosion resistance (especially to chlorides) and suitability for high-purity applications, offering excellent durability and ease of cleaning to meet stringent industry standards like GMP for pharmaceuticals and FDA for food. For extremely corrosive materials, specialized alloys like Duplex Stainless Steel or Hastelloy may be used.

Q3: How do CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems work on a vacuum mixer?

CIP/SIP systems automate the cleaning and sterilization process without disassembling the mixer. For CIP, cleaning solutions (e.g., water, detergent, acid, alkali) are circulated through spray balls and internal piping, effectively washing all contact surfaces. For SIP, steam is typically circulated to sterilize the interior surfaces. These systems ensure consistent, validated cleaning and sterilization, crucial for preventing cross-contamination in sensitive industries.

Q4: What types of agitators are common in vacuum mixer and when are they used?

Common agitators include:

- Anchor/Frame Agitator: For high-viscosity products, it scrapes the vessel wall to improve heat transfer and prevent product buildup.

- High-Shear Homogenizer (Rotor-Stator): For emulsification, dispersion, and particle size reduction, creating intense shear forces. Can be top-entry, bottom-entry, or external circulation.

- Propeller/Turbine Agitator: For low-viscosity liquids, providing bulk flow and blending.

- Planetary Mixer: For extremely high-viscosity pastes and putties, where multiple blades rotate on their own axes while orbiting a central axis, ensuring thorough mixing.

Q5: What are the typical energy consumption characteristics of a vacuum mixer?

Energy consumption varies significantly based on batch size, product viscosity, mixing speed, and duration. Modern vacuum mixer are equipped with Variable Frequency Drives (VFDs) for motors, which optimize energy usage by adjusting motor speed to match current process needs. Homogenizers are typically the most power-intensive components due to high shear requirements. Overall, a well-designed vacuum mixer prioritizes efficiency through optimized agitator design and advanced controls.

Q6: What maintenance is required for a vacuum mixer to ensure a long lifespan?

Regular maintenance includes checking and lubricating bearings, inspecting mechanical seals for wear or leakage, verifying vacuum pump performance, checking electrical connections, and calibrating sensors. For hygienic mixers, regular CIP/SIP cycle validation is also important. Adhering to the manufacturer's recommended preventative maintenance schedule, using genuine spare parts, and ensuring proper operator training significantly extends the lifespan of the equipment, often exceeding 15-20 years.

Q7: Can a vacuum mixer handle both heating and cooling processes?

Yes, most industrial vacuum mixer are equipped with a jacketed vessel design, allowing for precise temperature control. Heating can be achieved by circulating steam, hot water, or thermal oil through the jacket, while cooling is done by circulating chilled water or other cooling fluids. This capability is essential for managing exothermic reactions, maintaining optimal product viscosity, or facilitating phase changes (e.g., melting solids and cooling emulsions).

10. Conclusion: The Future of Precision Mixing and Why to Choose Vacuum Mixers

The landscape of industrial manufacturing is continuously evolving, with a growing emphasis on precision, efficiency, and product integrity. In this dynamic environment, the vacuum mixer stands as a cornerstone technology, offering unparalleled advantages in de-aeration, oxidation prevention, and achieving superior product homogeneity. Its critical role in sensitive industries like pharmaceuticals, food, cosmetics, and new materials underscores its indispensable nature for producing high-quality, stable, and safe products.

Investing in a high-quality vacuum mixer from a reputable manufacturer like Bossin Machinery is not merely a purchase; it's a strategic decision that empowers businesses to meet stringent regulatory requirements, optimize production processes, reduce waste, and ultimately deliver superior products to the market. The combination of advanced engineering, robust materials, meticulous manufacturing, and comprehensive after-sales support ensures that these machines offer long-term reliability and exceptional return on investment. As industries push for even higher standards of purity and performance, the demand for sophisticated vacuum mixer technology will only continue to grow, solidifying its position as a vital asset in modern production facilities.

References and Further Reading

- Grand View Research. (2023). Industrial Mixers Market Size, Share & Trends Analysis Report By Product, By End-use, By Region, And Segment Forecasts, 2023 - 2030. https://www.grandviewresearch.com/industry-analysis/industrial-mixers-market

- Journal of Food Engineering. (2018). Impact of Deaeration on Physicochemical Properties and Stability of Food Emulsions. (Example: For real world use, find a specific article that details this.)

- International Journal of Pharmaceutics. (2020). Design and Validation of Mixing Processes for Pharmaceutical Suspensions under Vacuum. (Example: For real world use, find a specific article that details this.)

- Chemical Engineering Forum. (2022). Advanced Mixing Technologies for High-Viscosity Slurries in Battery Manufacturing. (Example: For real world use, find a specific forum discussion or white paper that details this.)

This is the last article

Latest news

-

Air-Free Vacuum Mixers for Precise & Homogeneous Blending

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Precision Clipping

NewsAug.06,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line Integration&Compact Design

NewsAug.06,2025

-

Automatic Deboner Machine for High-Yield Processing

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision and Efficiency

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.06,2025