Novemba . 19, 2024 14:24 Back to list

Innovative Meat Tumbler Manufacturing Plants for Enhanced Food Quality and Efficiency

The Evolution and Importance of Meat Tumbler Factories

In today's global food industry, the processing and preparation of meat products have undergone significant advancements. Among these innovations, meat tumblers have emerged as pivotal machinery in the production process. These devices not only enhance the flavor and texture of meats but also improve production efficiency. The operation of meat tumbler factories is an intricate dance of technology and craftsmanship, transforming how meat is prepared for consumers.

Understanding Meat Tumblers

Meat tumblers are specialized machines designed to marinate, tenderize, and mix meat products. The tumbling process involves placing meat into a rotating drum along with various ingredients such as salt, spices, marinades, and sometimes even brine. As the drum rotates, the meat is not only coated with these ingredients but also undergoes a process that alters its texture, allowing it to absorb moisture and flavors more effectively.

The benefits of using meat tumblers extend beyond mere flavor enhancement. Tumbling can also improve the shelf life of meat products by ensuring even distribution of preserving agents. Additionally, the mechanical action of tumbling helps break down muscle fibers, leading to a more tender final product. This is particularly beneficial in commercial meat processing, where consistency and quality are paramount.

The Role of Meat Tumbler Factories

Meat tumbler factories play a crucial role in the production chain. These facilities are equipped with advanced machinery that meets high hygiene and safety standards required in food processing. The factories are not only responsible for manufacturing the tumblers themselves but also for ensuring that the whole process of meat tumbling is efficiently managed.

A typical meat tumbler factory incorporates various stages of production. The first step involves receiving raw materials, where quality control checks are performed to ensure that all inputs meet the necessary standards. Following this, the meat is prepared according to specifications, with various cuts being sorted based on the desired end product.

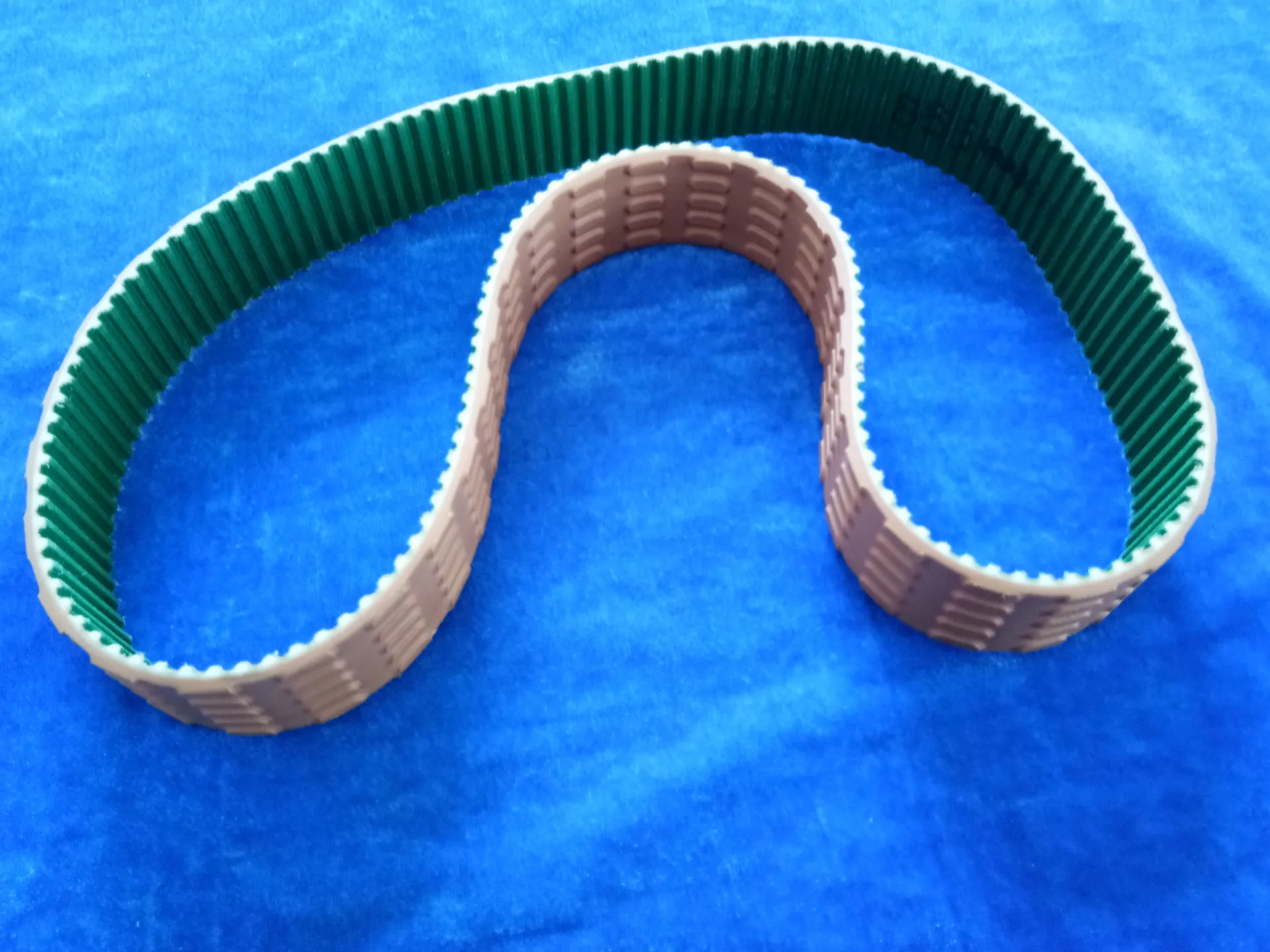

meat tumbler factories

Once the meat is ready, it is placed in the tumblers with predetermined amounts of seasoning and marinades. Modern factories often utilize automated systems to monitor and control the tumbling process, ensuring uniformity and minimizing the potential for human error. This technological integration not only enhances product quality but also increases production speeds, allowing factories to meet growing consumer demand.

Challenges Facing Meat Tumbler Factories

Despite the advantages provided by meat tumblers, factories face several challenges. The meat industry is heavily regulated, and factories must continuously adapt to changing food safety regulations and consumer preferences. There is an increasing demand for transparency in food sourcing and processing, prompting factories to invest in traceability systems that track meat from farm to table.

Additionally, sustainability concerns are rising in importance. As consumers become more aware of environmental issues, many meat tumbler factories are taking steps to minimize their carbon footprint. This includes optimizing energy use in machinery, reducing waste by recycling materials, and sourcing ingredients from responsible suppliers. The implementation of these practices not only addresses consumer concerns but also enhances the factory's reputation in a competitive market.

The Future of Meat Tumbler Factories

As technology continues to evolve, so too will the capabilities of meat tumbler factories. Innovations such as artificial intelligence and machine learning are expected to play a significant role in optimizing production processes and ensuring quality control. The use of data analytics can enable factories to predict trends and adjust their production strategies accordingly.

Moreover, as alternative protein sources gain popularity, traditional meat processing factories may begin diversifying their product lines to include plant-based alternatives. By incorporating meat tumbling techniques into the preparation of these products, factories can create a broader range of offerings that appeal to both meat lovers and those seeking plant-based options.

In conclusion, meat tumbler factories are integral to the modern meat processing industry. Through the advanced technology and methods they employ, these factories provide consumers with high-quality, flavorful, and safe meat products. As the industry evolves, the adaptability of meat tumbler factories will play a crucial role in shaping the future of food production.