Novemba . 06, 2024 01:21 Back to list

Supplier of Salt Brine Injection Solutions for Enhanced Performance Applications

The Significance of Salt Brine Injection and Innovative Suppliers

Salt brine injection is a vital process in various industries, especially in road maintenance and food preservation. With the increasing demand for effective and efficient de-icing solutions during winter months, the importance of high-quality salt brine and reliable suppliers has never been greater. This article aims to explore the significance of salt brine injection, the technology behind the process, and what to look for in a reputable supplier.

Understanding Salt Brine

Salt brine is a solution made of water and salt (typically sodium chloride) that plays a crucial role in melting ice and snow. The effectiveness of salt brine lies in its ability to lower the freezing point of water, which prevents icy conditions from developing on roads and pavements. This characteristic makes it a preferred choice for municipalities and road maintenance agencies during winter.

The Process of Salt Brine Injection

Salt brine injection can be deployed in several ways, from pre-treatment applications to direct spraying on icy roads. Pre-treating roads with salt brine before a snowfall helps prevent ice from bonding to the pavement, making snow removal easier and more effective. This proactive approach reduces the amount of material needed to maintain safe road conditions and minimizes the environmental impact associated with excessive salt application.

Benefits of Salt Brine Injection

1. Cost-Effectiveness Using salt brine can reduce overall road treatment expenditures. It requires less salt than traditional methods, resulting in lower costs over time for municipalities.

2. Environmental Responsibility Salt brine is more environmentally friendly than solid salt because it minimizes runoff and leaching into surrounding areas. This is particularly important in regions sensitive to salt damage.

3. Enhanced Safety Maintaining safer road conditions significantly reduces the risk of accidents during winter months. Salt brine helps create a safer driving environment for everyone.

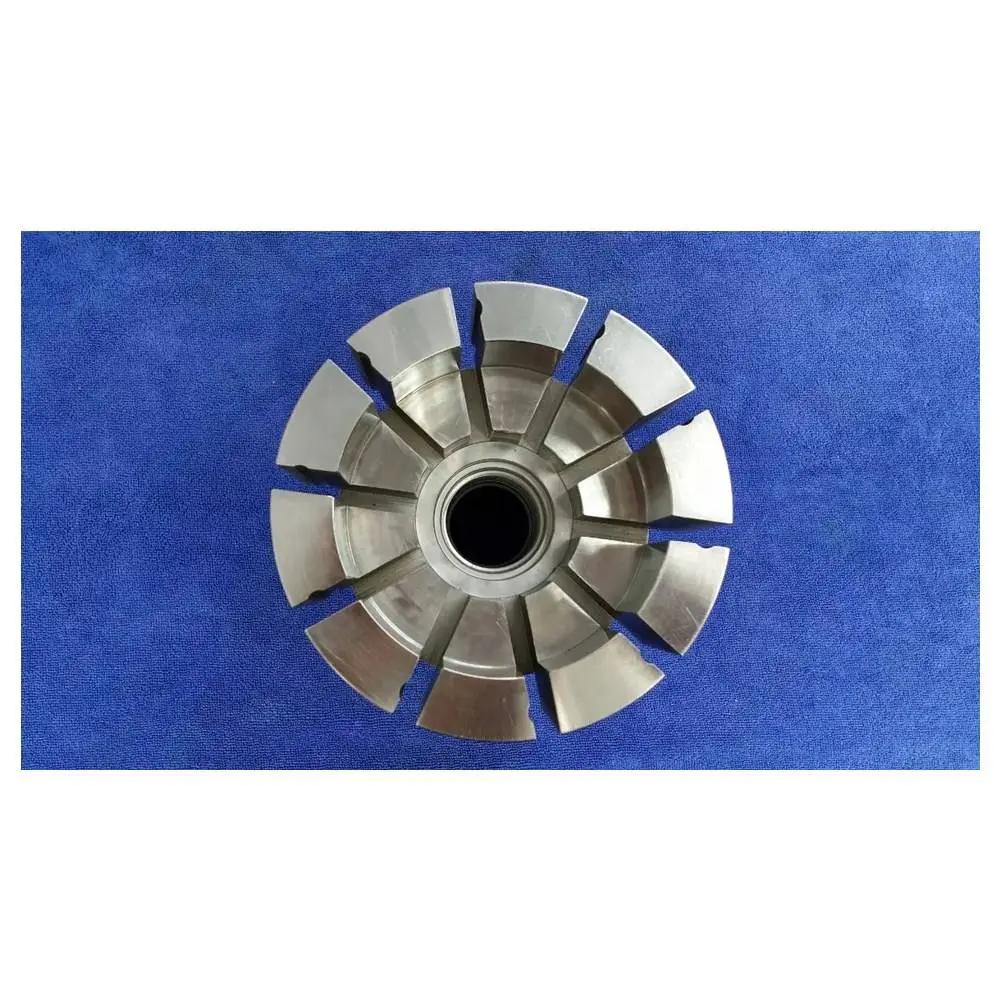

salt brine injection supplier

Choosing a Salt Brine Injection Supplier

Selecting the right supplier for salt brine injection is paramount for achieving optimal results. Here are some key factors to consider

1. Quality of Products Ensure that the supplier offers high-quality salt brine that meets industry standards. Consistent quality in the brine can significantly impact its effectiveness.

2. Custom Solutions A reputable supplier should be able to provide customized solutions based on specific needs. Factors such as regional climate, road conditions, and the volume of salt brine required can vary greatly, so tailored solutions are crucial.

3. Safety Standards Look for suppliers that adhere to safety and environmental regulations. The supplier should be aware of the environmental implications of salt use and strive to minimize ecological impacts.

4. Experience and Reputation Choosing a supplier with a proven track record in the industry is vital. Research their history, client testimonials, and case studies to understand their reliability and service quality.

5. Technical Support An excellent supplier will not only provide the product but also offer technical support and guidance on using salt brine injection effectively. This includes training for personnel on application techniques and equipment operation.

Innovations in Salt Brine Technology

Recent advancements in salt brine technology have opened new avenues for enhancing its effectiveness. Innovations such as the addition of corrosion inhibitors and the development of more efficient application equipment make salt brine an even more effective choice for road safety and maintenance.

Conclusion

Salt brine injection is an indispensable practice for efficient road maintenance in winter conditions, as well as for various applications in food preservation and agriculture. With the pressing need for effective de-icing solutions, businesses must prioritize selecting high-quality suppliers for their salt brine needs. Suppliers should be capable of providing quality products, customized solutions, and technical support to ensure optimal results. By investing time in finding the right salt brine supplier, municipalities and businesses can enhance safety, reduce costs, and minimize environmental impact—all critical factors in our increasingly demanding world.