Novemba . 10, 2024 14:15 Back to list

Wholesale Chicken Deboning Equipment for Efficient Meat Processing Solutions

The Wholesale Chicken Deboner Machine Revolutionizing Poultry Processing

In the poultry industry, efficiency and quality are paramount. As the demand for processed chicken continues to rise globally, manufacturers must adopt advanced technologies to streamline operations. One such innovation is the wholesale chicken deboner machine, a game-changer for meat processing plants and poultry suppliers. This article explores the functionality, benefits, and impact of these machines on the industry.

Understanding the Chicken Deboner Machine

A chicken deboner machine automates the process of separating meat from bones, a task traditionally performed by skilled workers. These machines utilize advanced cutting and separating technologies, which can handle various chicken parts such as breasts, thighs, and wings. Operating at high speeds, they significantly reduce the time required for deboning while ensuring consistency and precision in meat yield.

The design of these machines varies, ranging from small tabletop models suitable for smaller operations to large industrial systems capable of processing hundreds of chickens per hour. They are equipped with adjustable settings that allow operators to customize the thickness of the meat fillet, ensuring minimal waste and maximizing profitability.

Benefits of Wholesale Chicken Deboner Machines

1. Increased Efficiency One of the primary advantages of using a chicken deboner machine is the dramatic increase in processing speed. These machines can process a large volume of chicken in a shorter time than manual labor, making it possible for businesses to meet high demand consistently.

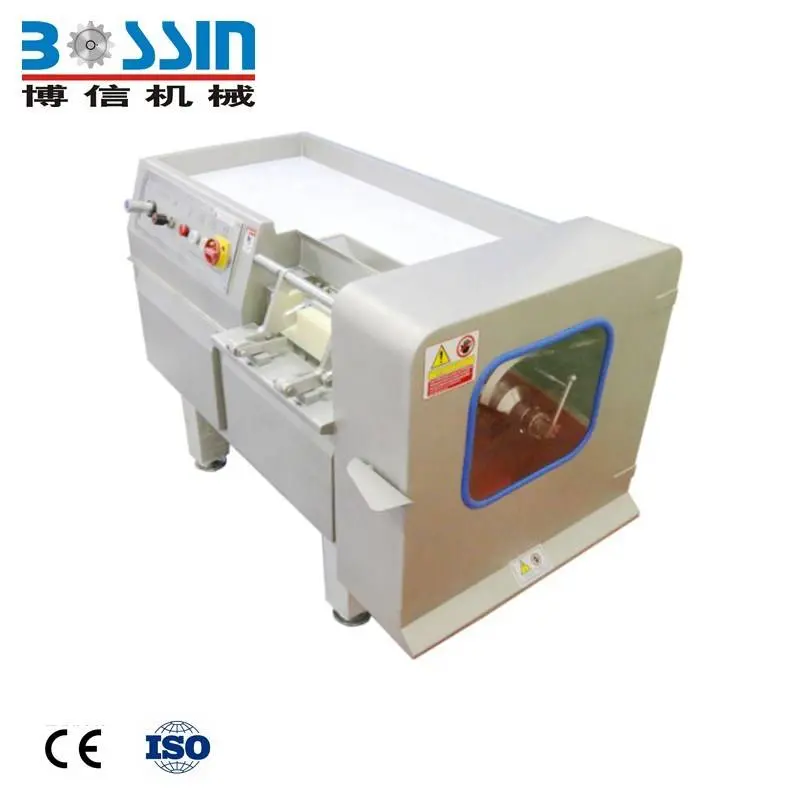

wholesale chicken deboner machine

2. Cost-Effectiveness While the initial investment in a deboner machine may be significant, the long-term savings are substantial. Businesses save on labor costs, reduce waste, and improve overall yield, leading to better profit margins. The automation of labor-intensive tasks also mitigates the risk of labor shortages in the industry.

3. Improved Product Quality With machines engineered for precision, the quality of deboned chicken is enhanced. The consistent cut and removal of bones result in a cleaner product, appealing to consumers who prioritize quality in their poultry purchases. Additionally, enhanced food safety measures integrated into modern machines reduce the risk of contamination.

4. Safety and Compliance Manual deboning can lead to workplace injuries and safety hazards. Automated machines mitigate these risks by minimizing human involvement in dangerous processes. Moreover, compliance with health and safety regulations is easier to achieve with machine-operated processes that follow strict sanitary protocols.

5. Versatile Applications Wholesale chicken deboner machines are not limited to just whole birds; they are also capable of processing different chicken parts efficiently. This versatility makes them invaluable in various sectors, including restaurants, supermarkets, and food processing plants.

The Future of Poultry Processing

The wholesale chicken deboner machine is just one example of how technology is shaping the future of the poultry industry. As manufacturers continue to invest in automation, the entire supply chain benefits from improved efficiency, safety, and product quality. Additionally, advancements in machine learning and artificial intelligence are poised to further enhance the performance of these machines, ensuring they adapt to meet changing market demands effectively.

In conclusion, the wholesale chicken deboner machine is revolutionizing poultry processing by streamlining operations and enhancing product quality. As the industry evolves, adopting such technologies will be crucial for businesses seeking to maintain a competitive edge. Embracing automation not only meets current demands but also positions companies for future growth in an ever-changing market. With these machines, the poultry industry can look forward to a more efficient and sustainable future.