Eyl . 22, 2024 01:21 Back to list

automatic sausage filler suppliers

The Rise of Automatic Sausage Filler Suppliers

In the food processing industry, efficiency and quality are paramount, especially when it comes to meat products. One of the innovations that have significantly transformed sausage production is the automatic sausage filler. These machines streamline the filling process, ensuring consistent quality while significantly increasing production capacity. In this article, we will explore the role of automatic sausage filler suppliers in the meat processing industry and the benefits they bring to businesses.

What is an Automatic Sausage Filler?

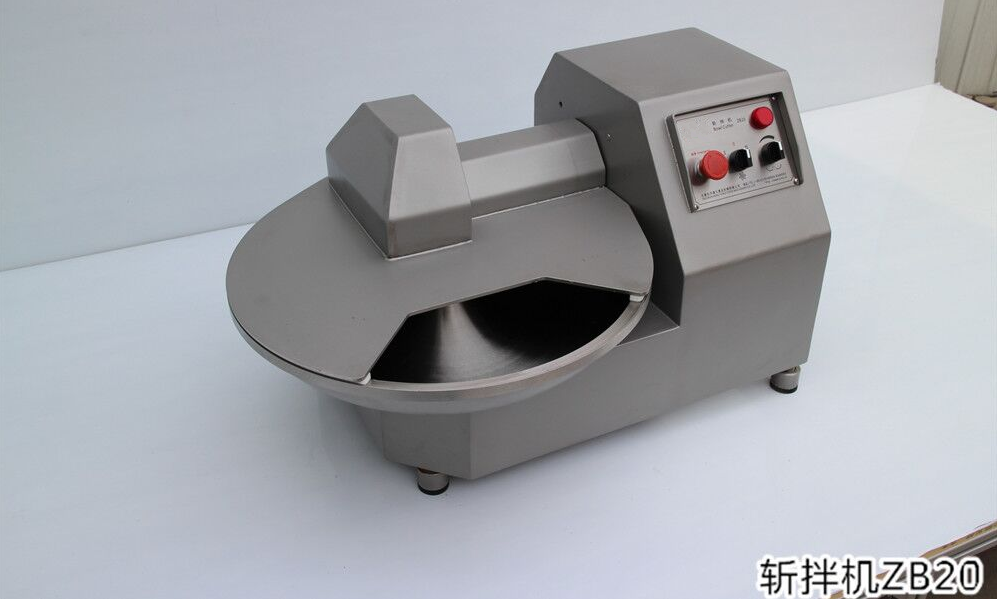

An automatic sausage filler, also known as a sausage stuffer, is a piece of equipment designed to fill casings with a meat mixture automatically. Unlike manual stuffing methods, which can be labor-intensive and inconsistent, automatic fillers allow for precise control over the filling process. They can handle various types of sausages, from traditional links to specialty products, and adapt to different casing sizes. This versatility makes them an essential tool for sausage manufacturers and butchers aiming to meet diverse consumer demands.

Key Benefits of Automatic Sausage Fillers

1. Increased Efficiency One of the most significant benefits of using automatic sausage fillers is the increase in production efficiency. These machines can fill casings much faster than manual methods, which means companies can produce more sausages in less time. This efficiency is especially crucial in today’s fast-paced food market, where consumers expect quick turnaround times.

automatic sausage filler suppliers

2. Consistency and Quality Automatic machines offer a level of consistency that manual filling simply cannot match. They ensure that each sausage is filled evenly, reducing the risk of air pockets and inconsistencies in texture. This uniformity not only enhances the product's quality but also boosts customer satisfaction.

3. Labor Cost Reduction By automating the filling process, businesses can significantly reduce labor costs. Fewer workers are needed to operate the machines, which can lead to savings in wages and training expenses. Moreover, since automatic fillers require less manual labor, companies can allocate their workforce to other areas that may need more attention.

4. Flexibility and Adaptability Modern automatic sausage fillers are designed with flexibility in mind. Many models can easily switch between different sizes and types of sausages, making them suitable for a wide range of products. This adaptability is particularly beneficial for businesses that want to diversify their product offerings and respond to changing market trends.

5. Improved Hygiene In an industry where food safety is critical, automatic fillers provide a more hygienic filling process compared to manual methods. These machines are typically designed with materials that are easy to clean, reducing the risk of contamination and helping businesses comply with health regulations.

Conclusion

The role of automatic sausage filler suppliers in the food processing sector cannot be understated. By providing advanced filling solutions, these suppliers enable businesses to enhance their production efficiency, improve product quality, and reduce costs. As the demand for high-quality meat products continues to grow, the reliance on automated solutions will likely increase, making automatic sausage fillers paramount in driving innovation and productivity in the industry. For manufacturers looking to stay competitive, investing in advanced filling technology is not just an option—it’s a necessity.