Ноя . 25, 2024 16:44 Back to list

Automated Production Line for Hamburger Patty Manufacturing and Quality Control

The Advancements in Automatic Hamburger Patty Production Lines

In the modern culinary landscape, automation has become an integral part of food production, especially in the fast-food industry. One of the most significant innovations is the automatic hamburger patty production line, which streamlines the manufacturing process, ensuring efficiency and consistency. With the rise in demand for hamburgers worldwide, these automated systems have revolutionized how patties are produced, meeting the needs of both large-scale manufacturers and small restaurants.

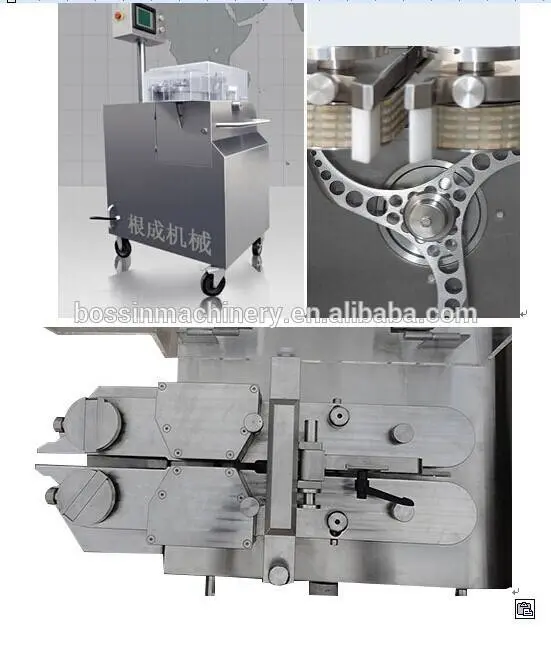

The production line typically starts with raw meat, which can be beef, chicken, or plant-based alternatives. The meat is first carefully inspected and processed into ground form, ensuring it meets safety and quality standards. This initial stage is crucial, as it lays the foundation for producing high-quality patties. Once the meat is prepared, the automatic line takes over, utilizing advanced machinery that shapes the ground meat into uniform patties. This process not only saves time but also ensures that each patty is consistent in size and weight.

One of the most significant advantages of an automatic hamburger patty production line is its ability to increase production rates dramatically. Manual production can be labor-intensive and time-consuming, often leading to inconsistencies in product quality. In contrast, an automated line can produce thousands of patties per hour, making it possible to meet large-scale demands without compromising quality. Additionally, automation minimizes human error, leading to fewer defective products and reducing waste.

automatic hamburger patty production line with c

Moreover, these production lines are equipped with cutting-edge technology that allows for customizations. Manufacturers can easily adjust the thickness, seasoning, and other specifications of the patties to cater to different consumer preferences and trends. This flexibility is vital in a market that increasingly values personalization in food options.

The automatic hamburger patty production line also contributes to enhanced food safety. The machinery is designed to reduce contact with human hands, thereby decreasing the risk of contamination. Furthermore, the automation process includes rigorous monitoring systems that ensure the meat is processed under hygienic conditions, adhering to health regulations.

In conclusion, the automatic hamburger patty production line represents a significant advancement in food production technology. It enhances efficiency, maintains consistency, and supports food safety—all while meeting the growing consumer demand for hamburgers. As the industry continues to evolve, these automated systems will play a crucial role in shaping the future of food production, ensuring that everyone has access to quality meals in a fast-paced world.