Лют . 14, 2025 08:06 Back to list

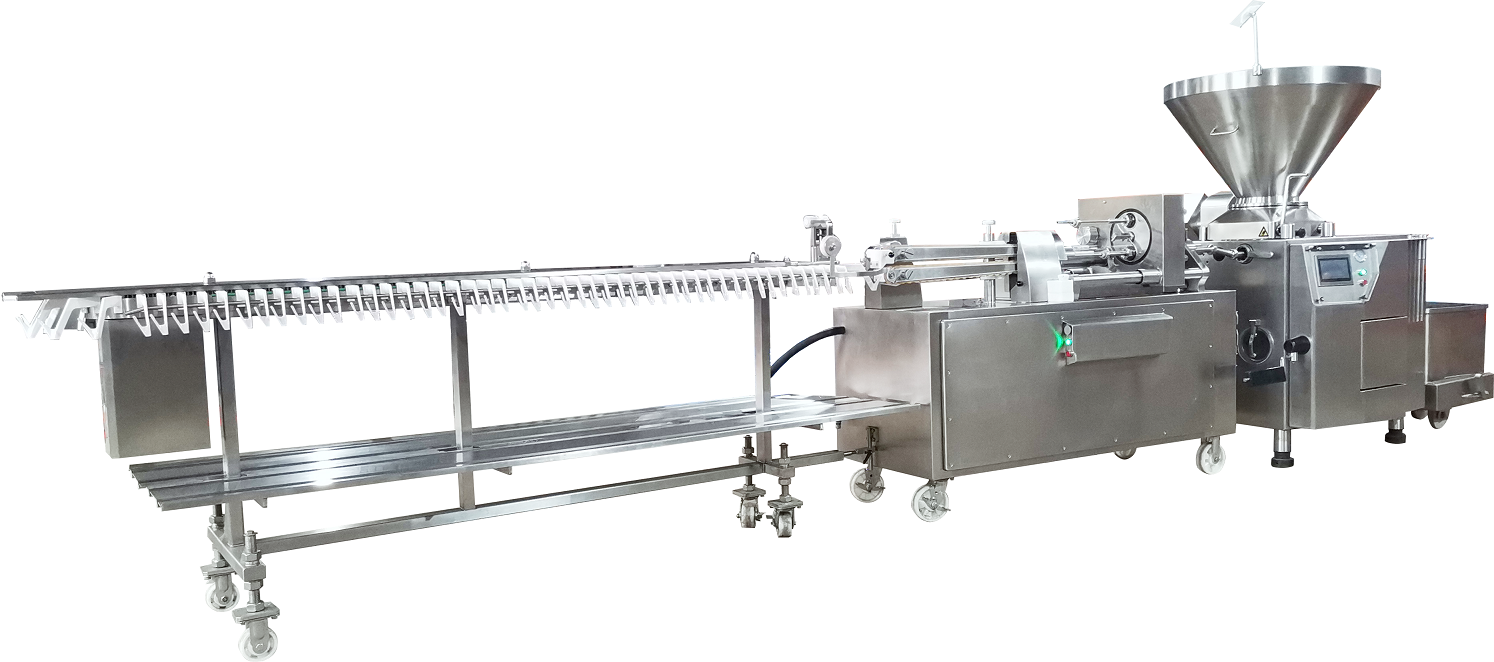

vacuum stuffer parts

Exploring the Essentials and Innovations in Vacuum Stuffer Parts

Smart Sensors and Monitoring Sensors that monitor consistency, temperature, and mixture properties in real-time allow for immediate adjustments, ensuring that the final products maintain premium quality. This technology underscores the focus on product excellence and safety. Eco-friendly Designs As sustainability becomes imperative, manufacturers are developing eco-friendly materials and energy-efficient systems to minimize environmental impact. This not only reduces carbon footprints but can also lower operational costs in the long run. Enhanced Durability and Maintenance The shift toward using high-performance alloys and composites enhances the lifespan of vacuum stuffer parts, reducing wear and tear. Furthermore, new designs prioritize accessibility and ease of part replacement, streamlining maintenance operations. Why Expertise Matters Choosing the right vacuum stuffer parts requires a balance of expertise and insight, particularly for businesses aiming to maintain a competitive edge in food processing. Expertise not only helps in selecting parts that fit specific operational needs but also ensures compliance with industry standards and regulations, thereby enhancing trustworthiness. Experts in vacuum stuffer technology provide invaluable guidance on the integration of advanced features, matching businesses with parts that optimize both performance and cost-effectiveness. Furthermore, partnering with reputed manufacturers and suppliers, known for their credibility and innovation, can enhance the overall reliability and longevity of equipment. Building Trust Through Proven Performance Trust in vacuum stuffer parts is built over time through consistent performance, adherence to quality standards, and effective after-sales support. Establishing partnerships with trusted suppliers who offer warranties and technical support can further solidify a business's reputation for quality and reliability in the marketplace. In conclusion, understanding the intricacies and innovations in vacuum stuffer parts is vital for any business involved in food processing. By leveraging expert knowledge and cutting-edge technology, companies can not only enhance product quality but also improve operational efficiency, ensuring sustained success in a competitive industry.

Smart Sensors and Monitoring Sensors that monitor consistency, temperature, and mixture properties in real-time allow for immediate adjustments, ensuring that the final products maintain premium quality. This technology underscores the focus on product excellence and safety. Eco-friendly Designs As sustainability becomes imperative, manufacturers are developing eco-friendly materials and energy-efficient systems to minimize environmental impact. This not only reduces carbon footprints but can also lower operational costs in the long run. Enhanced Durability and Maintenance The shift toward using high-performance alloys and composites enhances the lifespan of vacuum stuffer parts, reducing wear and tear. Furthermore, new designs prioritize accessibility and ease of part replacement, streamlining maintenance operations. Why Expertise Matters Choosing the right vacuum stuffer parts requires a balance of expertise and insight, particularly for businesses aiming to maintain a competitive edge in food processing. Expertise not only helps in selecting parts that fit specific operational needs but also ensures compliance with industry standards and regulations, thereby enhancing trustworthiness. Experts in vacuum stuffer technology provide invaluable guidance on the integration of advanced features, matching businesses with parts that optimize both performance and cost-effectiveness. Furthermore, partnering with reputed manufacturers and suppliers, known for their credibility and innovation, can enhance the overall reliability and longevity of equipment. Building Trust Through Proven Performance Trust in vacuum stuffer parts is built over time through consistent performance, adherence to quality standards, and effective after-sales support. Establishing partnerships with trusted suppliers who offer warranties and technical support can further solidify a business's reputation for quality and reliability in the marketplace. In conclusion, understanding the intricacies and innovations in vacuum stuffer parts is vital for any business involved in food processing. By leveraging expert knowledge and cutting-edge technology, companies can not only enhance product quality but also improve operational efficiency, ensuring sustained success in a competitive industry.

Next:

Latest news

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision, Efficiency, Innovation

NewsAug.03,2025

-

Sausage Link Cutter JC999-03 | Fast & Precise Sausage Slicing Tool

NewsAug.03,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, High Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, Efficient Meat Processing

NewsAug.03,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Efficiency

NewsAug.03,2025