دسمبر . 25, 2024 19:22 Back to list

Meat Injector Machine Manufacturers and Production Facilities Overview

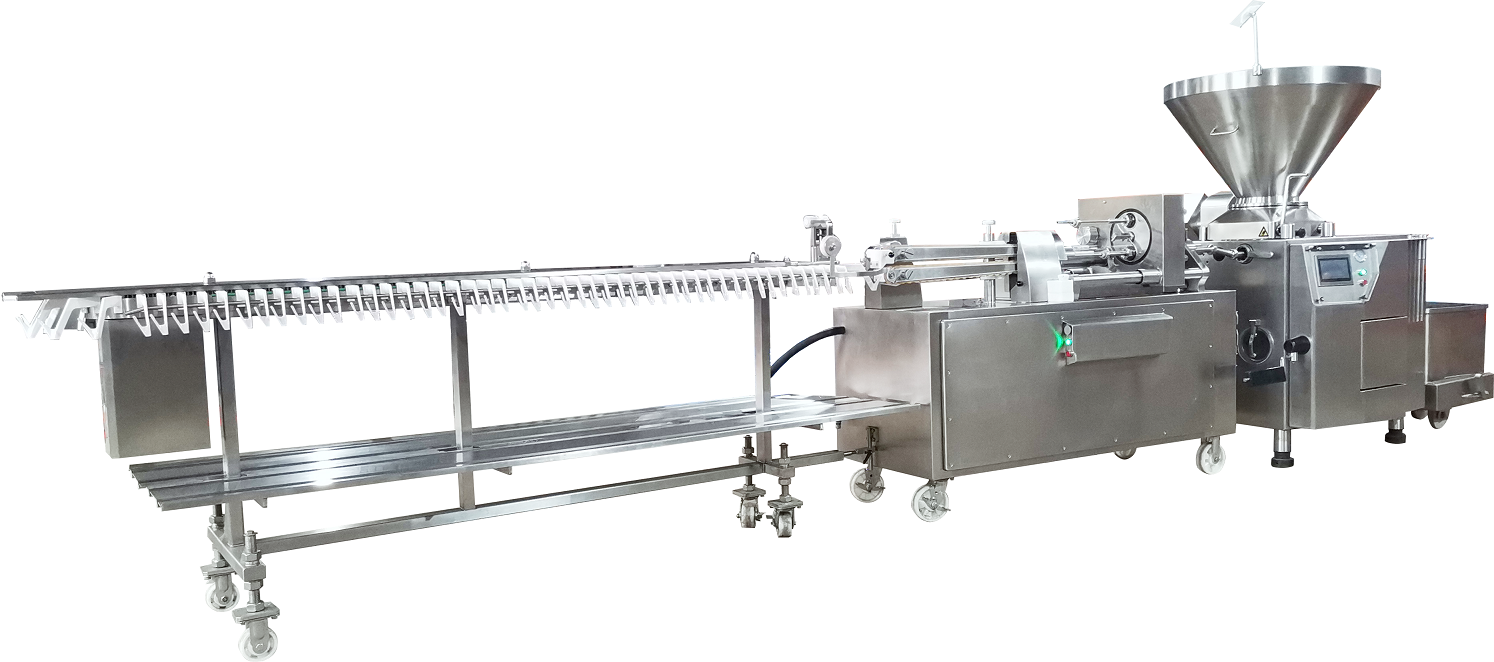

Exploring Meat Injector Machine Factories An Essential Component in Modern Food Processing

In the dynamic world of food processing, efficiency and quality are paramount. One of the critical innovations that have propelled the meat industry into a new era is the meat injector machine. These machines are designed to enhance flavor, improve texture, and boost overall product quality by infusing meats with marinades, brines, and other flavoring agents. As consumer preferences for flavorful and high-quality meat products continue to rise, the importance of meat injector machine factories is becoming increasingly clear.

The Role of Meat Injector Machines

Meat injector machines serve a vital function in meat processing by ensuring that flavoring agents penetrate deep into the meat fibers. This process not only enhances the taste but also contributes to moisture retention during cooking, resulting in a tender and juicy final product. Additionally, these machines help to improve the consistency of flavor across different batches of meat, which is crucial for maintaining brand quality and customer satisfaction.

The Manufacturing Process

Meat injector machine factories employ sophisticated technology to produce these essential machines. The manufacturing process involves several stages, including research and development, design, assembly, and quality control.

1. Research and Development (R&D) The first stage involves extensive research into the latest advancements in food processing technology. Engineers and food technologists work closely together to develop machines that are efficient, durable, and easy to operate. This stage also considers ergonomic designs that reduce the physical strain on operators.

2. Design Once the R&D phase is complete, the design team drafts detailed blueprints for the machines. This includes selecting materials that can withstand harsh environments, such as stainless steel for hygiene and durability. The design must also comply with food safety standards and regulations to ensure that the machines are safe for food contact.

meat injector machine factories

3. Assembly After the design is finalized, the manufacturing process moves to the assembly line. Skilled workers, guided by precision engineering techniques, put together different components of the machine, including pumps, injectors, and control systems. Automation plays a significant role in this process, allowing for increased efficiency and reduced human error.

4. Quality Control Quality assurance is critical in food processing machinery. Each machine undergoes rigorous testing to ensure it meets industry standards and performs as expected. Factories often employ advanced calibration techniques to ensure that the injection mechanisms deliver uniform distribution of marinades and brines.

Industry Trends and Innovations

In recent years, the meat injector machine sector has seen numerous innovations aimed at enhancing performance, reducing production times, and increasing energy efficiency. One significant trend is the integration of smart technology. Modern meat injector machines are now equipped with IoT (Internet of Things) capabilities, allowing them to collect data on performance metrics. This data can be used for predictive maintenance, thereby minimizing downtime and ensuring continuous production.

Moreover, consumer preferences are also pushing factories to adapt. For instance, as plant-based alternatives grow in popularity, some meat injector machines are being designed to accommodate a wider range of products, including hybrid plant-meat mixtures. This adaptability is crucial for factories looking to diversify their offerings and remain competitive.

Conclusion

As the meat industry continues to evolve, the role of meat injector machine factories becomes increasingly significant. These factories are not just producing machines; they are creating solutions that enhance the quality and flavor of meat products. By investing in advanced technology and continuously improving their processes, meat injector machine manufacturers are poised to meet the demands of a changing marketplace.

In summary, meat injector machine factories are at the forefront of innovation in the food processing industry, driving improvements in quality and efficiency. As consumer expectations continue to rise and the industry adapts to new trends, these factories will play an essential role in shaping the future of meat production, ensuring that consumers enjoy delicious and high-quality meat products.