Dek . 04, 2024 21:45 Back to list

injection machine factory

The Evolution and Impact of Injection Machine Factories

Injection molding has emerged as one of the most efficient and versatile manufacturing processes in the industrial sector. The term injection machine factory refers to the facilities where these advanced machines are manufactured, tested, and distributed. This article delves into the significance, development, and modern advancements in injection machine factories and their impact on various industries.

The Basics of Injection Molding

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. This process is suitable for a wide range of materials, including plastics, metals, and ceramics. The popularity of injection molding stems from its ability to create complex shapes with high precision and repeatability. The efficiency of this process significantly reduces waste and production time, making it an essential technique for manufacturers aiming to optimize their operations.

The Role of Injection Machine Factories

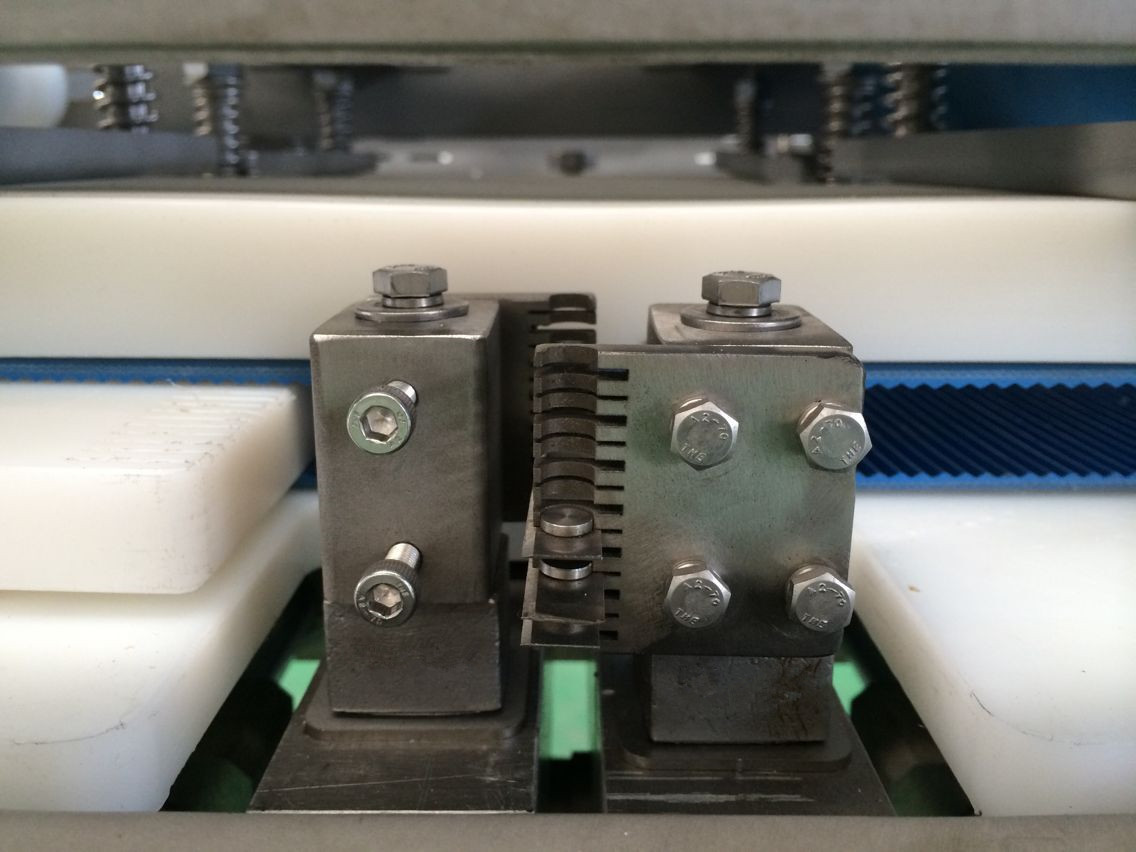

Injection machine factories are the backbone of the injection molding industry. These facilities specialize in the production of injection molding machines, which are composed of various components such as injection units, clamping units, and control systems. The complexity of these machines requires a high degree of engineering precision and technological know-how. These factories not only produce the machines but also provide maintenance, upgrades, and support services to ensure optimal performance and longevity.

Historical Development

The journey of injection molding machines can be traced back to the early 19th century when the first plastic injection molding machines were patented. Initially, these machines were rudimentary by today's standards, primarily used for creating simple items from natural materials like rubber. As technology progressed, especially in the mid-20th century, the introduction of synthetic polymers revolutionized the industry. Injection machine factories began to evolve, incorporating advanced technologies and high-performance materials to meet the rising demand for more complex and durable products.

Technological Advancements

In recent years, injection machine factories have embraced innovative technologies to enhance production efficiency and quality. The integration of automation and robotics has streamlined operations, allowing for faster cycle times and reduced labor costs. Additionally, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) have enabled manufacturers to design and produce more intricate mold geometries.

injection machine factory

Furthermore, the development of energy-efficient injection molding machines has reduced operational costs and minimized environmental impact. These machines are designed to consume less energy while maintaining high performance levels. The pursuit of sustainability has also led to the rise of bio-based and recyclable materials for injection molding, pushing factories to adapt and innovate.

Global Impact

Injection machine factories have a significant impact on the global economy. They support various industries, including automotive, consumer goods, medical devices, and electronics. The ability to produce high-quality parts at scale has made injection molding the preferred choice for many manufacturers. Consequently, the growth of these factories contributes to job creation, technological advancement, and international trade.

Moreover, as globalization progresses, injection machine factories are increasingly setting up operations in emerging markets. This shift not only provides local economies with much-needed investment and infrastructure but also helps companies optimize their supply chains. The demand for faster production and lower costs has prompted many manufacturers to diversify their production locations, thereby enhancing their competitiveness in the global market.

The Future of Injection Machine Factories

Looking ahead, the future of injection machine factories appears promising. As industries continue to evolve and the demand for customized products increases, these factories will need to adapt continuously. The incorporation of Industry 4.0 principles, including the Internet of Things (IoT) and artificial intelligence (AI), will likely transform factory operations, enhancing productivity and reducing downtime.

In addition, ongoing advancements in materials science may lead to new fuel-efficient and eco-friendly products, further driving innovation in the sector. Injection machine factories that embrace these changes will play a vital role in shaping the future of manufacturing.

Conclusion

Injection machine factories have come a long way since their inception, evolving into sophisticated facilities that drive the global manufacturing landscape. The blend of advanced technology, engineering prowess, and a commitment to sustainability positions these factories at the forefront of industrial innovation. As the demand for efficient and high-quality production continues to rise, injection machine factories will remain crucial in supporting various sectors and shaping the future of manufacturing.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|sausage production line,pneumatic technology

NewsAug.07,2025

-

Air-Free Vacuum Mixers for Precise & Homogeneous Blending

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Precision Clipping

NewsAug.06,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line Integration&Compact Design

NewsAug.06,2025

-

Automatic Deboner Machine for High-Yield Processing

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision and Efficiency

NewsAug.06,2025