Yan . 06, 2025 11:23 Back to list

sausage production line

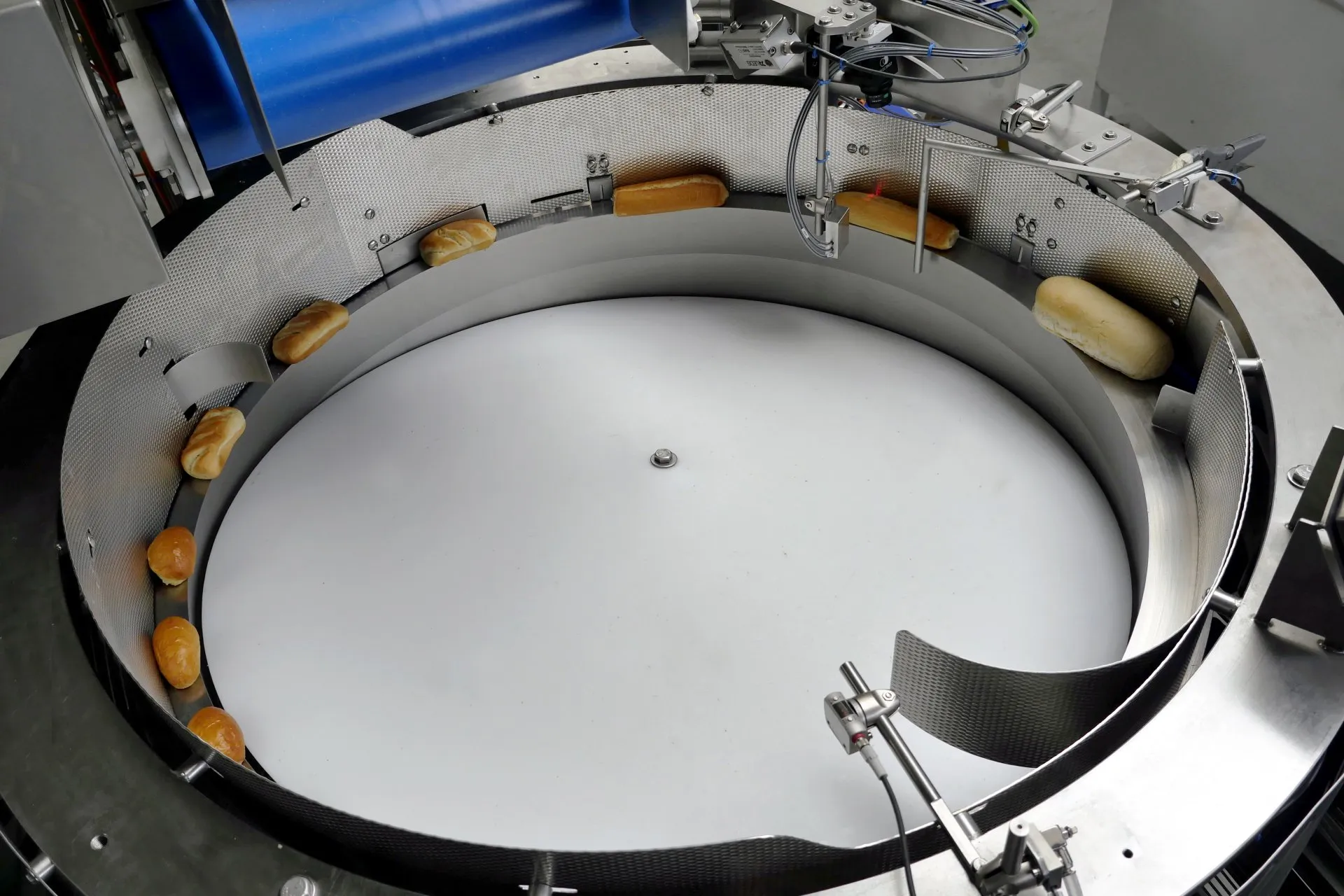

Sausage production lines are the backbone of efficient sausage manufacturing, transforming raw ingredients into a variety of delicious products. These highly specialized systems merge traditional culinary craftsmanship with state-of-the-art technology, ensuring consistent quality while enhancing productivity.

Experience drives the evolution of sausage production lines. Over decades, industry pioneers have honed methods to fine-tune each phase of production. From grinding and mixing to casing and cooking, the process is streamlined to maintain flavor and texture. Each machine in the line is designed for a specific task, minimizing human intervention and ensuring product uniformity.

Innovation in sausage manufacturing reflects deep expertise. Engineers and food scientists collaborate to develop production lines that accommodate diverse product ranges, such as fresh, cooked, or dry sausages. This flexibility is vital for manufacturers aiming to cater to varied consumer preferences and dietary needs. The integration of automation is pivotal—machines are now equipped with advanced sensors and control systems that monitor ingredient ratios and temperatures with pinpoint accuracy, leading to superior sausage quality.

Furthermore, the implementation of computerized systems in production lines bolsters efficiency and reduces waste. Automated slicing and packaging units, for example, not only speed up the manufacturing process but also ensure hygiene and product longevity.

sausage production line

Authoritativeness in sausage production lines stems from stringent compliance with industry standards and regulations. Companies invest in certifications to ensure their equipment meets international safety and quality benchmarks. This commitment to excellence reinforces their reputation, making them authoritative voices in artisanal and industrial sausage production.

Trustworthiness is core to any successful production line. In an era where consumers are increasingly conscious of food safety and authenticity, manufacturers prioritize transparency. Many have adopted traceability systems that allow the entire production process to be audited and verified. This includes tracking the origin of ingredients, monitoring each step of production, and ensuring adherence to health regulations.

Moreover, rigorous cleaning protocols are integrated into production cycles to prevent contamination, further solidifying consumer trust. Production lines are designed with materials that can withstand regular sanitation while minimizing the risk of compromising machinery or product quality.

In summary, a modern sausage production line encapsulates a harmonious blend of experience, expertise, authority, and trust. It is a testament to how traditional food production can evolve using technology to meet contemporary demands. Manufacturers who invest in state-of-the-art production lines not only enhance their operational capabilities but also reinforce their standing in the competitive food industry landscape.