Th10 . 19, 2024 01:44 Back to list

vacuum filler machine factories

The Rise of Vacuum Filler Machine Factories A Game Changer in Food Processing

In recent years, the food processing industry has seen remarkable advancements, particularly through the utilization of innovative machinery. Among these advancements, vacuum filler machines have emerged as pivotal tools in enhancing the efficiency and quality of food production. As demand for these machines grows, vacuum filler machine factories are blossoming across the globe, significantly reshaping the landscape of food processing.

What is a Vacuum Filler Machine?

A vacuum filler machine is designed to fill casings with a variety of products, such as sausages, meat mixes, and even non-meat items like cheese or plant-based alternatives. The core function of this machine lies in its ability to remove air from the filling process, which prevents spoilage and enhances the quality of the final product. By maintaining a vacuum environment, these machines help in preserving flavor and texture, making them indispensable for manufacturers looking to maintain high standards in their offerings.

Benefits of Vacuum Fillers

One of the most significant advantages of vacuum filler machines is their efficiency. Traditional filling methods can be labor-intensive and time-consuming. In contrast, vacuum fillers not only speed up the process but also ensure a more consistent and accurate fill. This precision helps reduce waste and minimize the use of raw materials, ultimately leading to cost savings for producers.

Moreover, vacuum filling technology has a positive impact on product quality. The absence of air during the filling process helps to maintain the integrity of the ingredients, which is especially crucial for products sensitive to oxidation. This results in fresher-tasting products that can have a longer shelf life, a significant consideration in today’s competitive market.

The Role of Factories

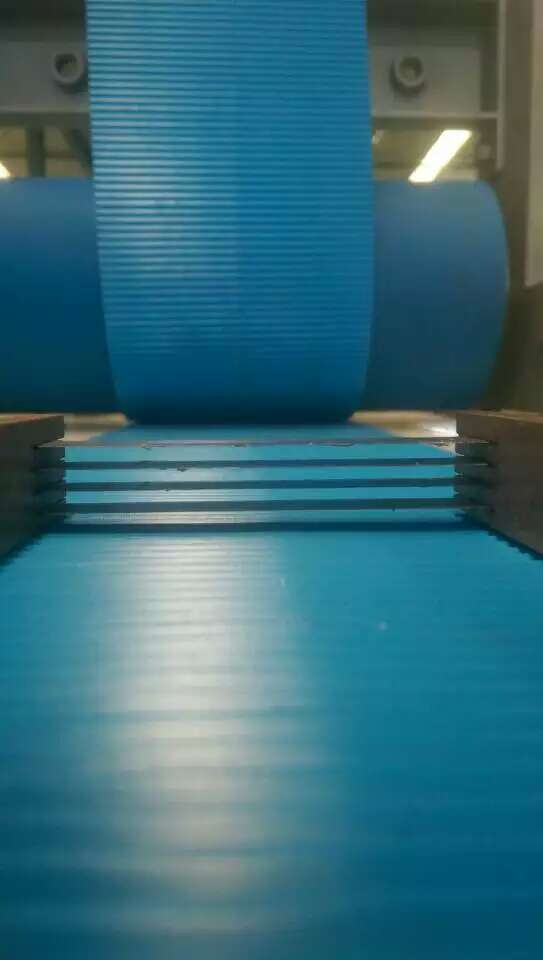

vacuum filler machine factories

As demand for vacuum fillers continues to rise, factories dedicated to their production are becoming more prevalent. These factories are not just manufacturing machines; they are also innovating. The leading vacuum filler machine factories are focused on research and development to enhance the technological features of their machines.

Modern vacuum fillers now come equipped with digital interfaces, automation capabilities, and integration with other food processing technologies. For instance, the ability to connect with inventory management systems allows manufacturers to streamline operations and improve production planning. Furthermore, the introduction of energy-efficient models aligns with the global push towards sustainability in manufacturing processes.

Global Impact

The growth of vacuum filler machine factories is not limited to one region; they are emerging worldwide. Countries with robust food production industries, such as Germany, the United States, and China, are investing heavily in these technologies. In Germany, for example, manufacturers are keenly focused on automation and precision engineering, producing some of the most advanced vacuum fillers in the market. Meanwhile, emerging economies in Asia are beginning to adopt these technologies, increasing their production capabilities and improving food safety standards.

Challenges and Future Developments

However, the development of vacuum filler machine factories is not without its challenges. The initial investment cost for such advanced machinery can be a barrier, particularly for small-scale producers. Additionally, competition is increasing as more players enter the market, which could lead to price wars that might affect manufacturing standards.

Looking ahead, the future of vacuum filler machine factories appears bright. With the continued focus on innovation and efficiency, these factories are poised to not only meet the demands of contemporary food processing but also lead the way in sustainable practices. As manufacturers become more aware of the environmental impact of their operations, the push for energy-efficient and eco-friendly machines will likely shape the direction of future developments.

In conclusion, vacuum filler machine factories play a crucial role in transforming the food processing industry. By delivering efficient, high-quality machinery, they not only enhance production capabilities but also contribute significantly to the overall quality of food products. As technology continues to evolve and consumer preferences shift, these factories will remain at the forefront of the food manufacturing revolution.

Latest news

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery|Sausage Production Line, Food Processing Machinery

NewsAug.05,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision, Efficiency, Durability

NewsAug.05,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Sausage Production&Efficient Clipping Technology

NewsAug.05,2025

-

Pneumatic Clipping Machine: Sausage Production Efficiency & Advanced Tech | Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.05,2025

-

Servo Motor Sausage Cutter Spare Parts | Precision Components

NewsAug.05,2025

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025