8 сар . 09, 2025 03:20 Back to list

High-Speed Sausage Filler-Linker-Hanger Line | Automated Efficiency

In the rapidly evolving global food industry, the demand for processed meat products, particularly sausages, continues to surge. This growth is driven by changing consumer lifestyles, urbanization, and a preference for convenient food options. To meet this escalating demand while maintaining quality and profitability, manufacturers are increasingly turning to advanced automation. At the forefront of this technological revolution is the High speed Sausage filler-linker-hanger line, a quintessential solution designed to optimize every stage of sausage production from filling to linking and hanging. This comprehensive overview delves into the intricacies of this pivotal machinery, exploring its technical prowess, operational advantages, and strategic importance in modern food processing plants.

Industry Trends and Market Dynamics in Sausage Production

The global sausage market is characterized by several key trends: increasing consumption of processed meats, a growing emphasis on food safety and hygiene, and the incessant pursuit of operational efficiency. Consumers are more discerning, demanding not only variety but also products free from contaminants and produced ethically. This necessitates the adoption of state-of-the-art machinery that can deliver high throughput without compromising on quality or safety standards.

Automation plays a crucial role in addressing these demands. High speed Sausage filler-linker-hanger line systems reduce reliance on manual labor, which can be inconsistent and prone to human error, thereby enhancing product uniformity and minimizing contamination risks. Furthermore, the rising cost of labor globally makes automation a more economically viable long-term investment. Sustainability is another driving factor, with manufacturers seeking solutions that optimize resource utilization, reduce waste, and improve energy efficiency. The High speed Sausage filler-linker-hanger line aligns perfectly with these trends, offering a pathway to scalable, hygienic, and cost-effective production.

Market data indicates a steady growth in the automated food processing equipment sector. According to reports, the global meat processing equipment market is projected to reach significant valuations by the end of the decade, with high-speed production lines being a major contributor to this growth. For example, a report by MarketsandMarkets in 2023 projected the meat processing equipment market size to grow from USD 10.9 billion in 2023 to USD 14.5 billion by 2028, at a CAGR of 5.8%. This underscores the strategic importance of investing in robust, reliable, and technologically advanced machinery like the High speed Sausage filler-linker-hanger line.

Understanding the High Speed Sausage Filler-Linker-Hanger Line

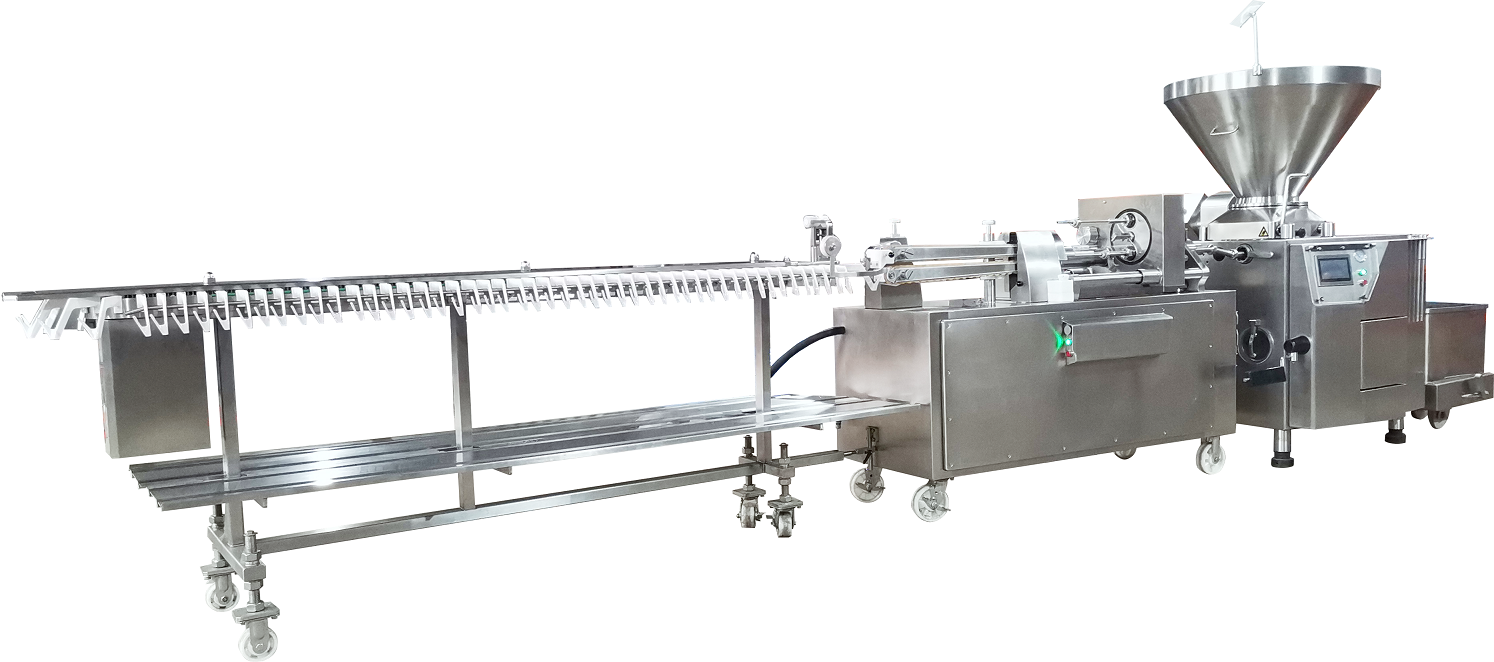

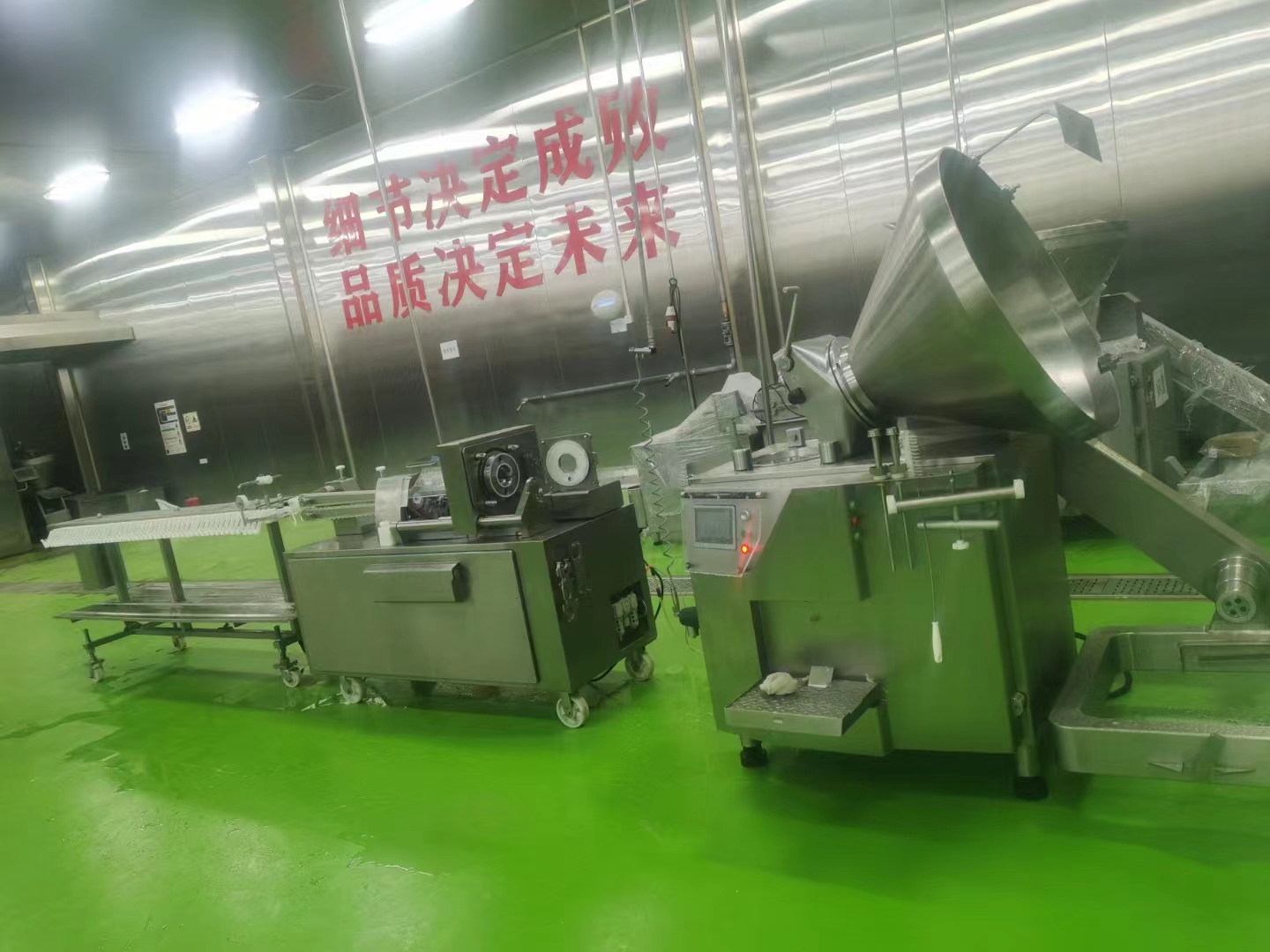

The High speed Sausage filler-linker-hanger line is an integrated system designed for the continuous and automated production of various types of sausages, from frankfurters and bratwurst to specialty sausages. It combines three critical stages of sausage manufacturing into one seamless process: filling, linking, and hanging. This integration dramatically reduces bottlenecks, improves overall throughput, and ensures product consistency. This holistic approach to automation is what sets these lines apart from individual machines performing discrete tasks.

Core Components and Technical Parameters

A typical High speed Sausage filler-linker-hanger line comprises several sophisticated modules, each performing a specialized function. These include:

- Vacuum Filler: The heart of the system, responsible for precisely portioning and filling the sausage emulsion into natural or artificial casings. Modern fillers utilize vacuum technology to prevent air pockets, ensuring a dense, uniform product and improving shelf life by reducing oxidation. The advanced servo drive technology in these fillers allows for highly accurate portioning, often within a gram, leading to significant material savings.

- Linking Unit: This module twists or clips the filled casing at predefined lengths, creating individual sausages. High-speed linking units can handle thousands of links per minute, maintaining precise dimensions and preventing breakage. Some systems employ innovative rotary linking technology for superior speed and gentle handling of delicate casings.

- Hanging Unit (or Hanger): Automatically transfers the linked sausages onto smoke sticks or hanging racks, preparing them for subsequent processing steps such as smoking, cooking, or chilling. This automation eliminates manual handling, enhancing hygiene and efficiency, and ensuring consistent product spacing for uniform processing.

- Control System: Advanced PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems provide intuitive control over the entire line, allowing for precise parameter adjustments, recipe management, and real-time monitoring of production data. Leading systems offer remote diagnostics and integration capabilities for Industry 4.0 environments.

- Cleaning-in-Place (CIP) System: Many modern lines integrate CIP capabilities, enabling automated internal cleaning and sanitization without extensive disassembly, crucial for maintaining food safety standards and reducing downtime.

Below is a typical parameters table for a High speed Sausage filler-linker-hanger line, highlighting key specifications that define its performance and capabilities, demonstrating its capacity for large-scale operations:

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Production Capacity | Up to 3,000 kg/hour | Maximum output capacity, indicating how much sausage can be processed per hour, significantly impacting operational throughput. |

| Linking Speed | Up to 1,500 links/minute | The rate at which individual sausages are linked and portioned, directly correlating to the line's efficiency. |

| Portioning Accuracy | ±0.5g to ±1.5g | Precision of individual sausage weight, crucial for product consistency, regulatory compliance, and cost control by minimizing 'giveaway'. |

| Casing Diameter Range | 13 mm - 50 mm (adjustable) | Accommodates various natural or artificial casing sizes, offering flexibility for different product types. |

| Power Requirement | 20 kW - 50 kW (depending on model) | Electrical power consumption for operation, important for energy efficiency calculations. |

| Machine Dimensions (L x W x H) | Approx. 5m x 2m x 2.5m | Overall physical footprint of the integrated line, vital for plant layout planning. |

| Material Contact Parts | Food-grade Stainless Steel (SUS304/316L) | Ensures hygiene, corrosion resistance, and compliance with stringent food safety regulations like FDA and USDA. |

| Control System | PLC with HMI Touchscreen | Enables intuitive operation, precise recipe management, real-time diagnostics, and remote access capabilities. |

| Compressed Air Pressure | 0.6 - 0.8 MPa | Required pneumatic pressure for various operational components, ensuring smooth mechanical functions. |

These parameters showcase the sophisticated engineering behind the High speed Sausage filler-linker-hanger line, designed to meet the rigorous demands of industrial-scale food production. The ability to precisely control portioning and high linking speeds are central to its value proposition.

Manufacturing Process: From Raw Material to Precision Machine

The construction of a High speed Sausage filler-linker-hanger line involves a meticulous manufacturing process to ensure durability, hygiene, and precision. The selection of materials is paramount, with food-grade stainless steel (SUS304 or SUS316L) being the standard for all parts that come into contact with food. SUS316L is particularly valued for its enhanced corrosion resistance, especially against chlorides, making it ideal for the often-harsh environments of food processing plants where brine and aggressive cleaning agents are frequently used. This superior material choice directly contributes to the machine's longevity and hygienic properties.

The manufacturing process typically includes:

- Material Sourcing and Quality Check: High-quality stainless steel sheets, pipes, and components are procured from certified suppliers. Incoming materials undergo strict quality inspection, including spectrographic analysis, to verify chemical composition and mechanical properties, ensuring they meet industry standards such as ASTM A240 for stainless steel.

- Precision Cutting and Forming: Advanced laser cutting or plasma cutting technologies are used to achieve precise component shapes with minimal material waste. Bending and forming machines then give these parts their required three-dimensional forms, ensuring structural integrity and precise fit.

- Machining (CNC): Critical components requiring high precision, such as pump housings, valve bodies, linking mechanisms, and servo motor mounts, are subjected to Computer Numerical Control (CNC) machining. This ensures micron-level accuracy (e.g., tolerances of ±0.01 mm), critical for consistent portioning, smooth operation, and minimal wear. CNC machining allows for complex geometries and tight tolerances, which are vital for the mechanical efficiency and extended lifespan of the High speed Sausage filler-linker-hanger line.

- Welding: Components are joined using advanced welding techniques, predominantly TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Special attention is paid to creating smooth, crevice-free welds that prevent bacterial growth and facilitate easy cleaning. Weld integrity is often checked using non-destructive testing (NDT) methods like dye penetrant inspection or X-ray radiography for critical joints, ensuring structural soundness and hygiene.

- Surface Finishing and Polishing: All food-contact surfaces are meticulously polished to a high Ra (Roughness Average) value, typically below 0.8 µm (or even 0.4 µm for ultimate hygiene in critical areas). This mirror-like finish prevents product adhesion, simplifies cleaning, reduces biofilm formation, and enhances corrosion resistance, aligning with EHEDG (European Hygienic Engineering & Design Group) guidelines.

- Assembly: Skilled technicians assemble the various modules, integrating mechanical, electrical, and pneumatic systems. Each sub-assembly is thoroughly tested before final integration into the complete High speed Sausage filler-linker-hanger line.

- Calibration and Testing: Once assembled, the entire line undergoes rigorous factory acceptance testing (FAT). This includes performance tests (e.g., maximum speed, portioning accuracy, linking consistency over extended runs), safety checks, electrical tests, and simulated production runs with actual product where feasible. Compliance with international standards such as ISO (e.g., ISO 22000 for food safety management) and CE (Conformité Européenne) marking for European markets is verified. This ensures the machine is ready for immediate deployment and meets all contractual specifications.

- Quality Control: Throughout the entire manufacturing process, stringent quality control checks are performed at every stage, adhering to ISO 9001 quality management principles. This ensures that every machine leaving the factory meets the highest standards of reliability, safety, and performance, guaranteeing customer satisfaction and long-term value.

The average service life of a well-maintained High speed Sausage filler-linker-hanger line from a reputable manufacturer can exceed 15-20 years, even under continuous, demanding industrial operation. This exceptional longevity is a testament to the robust design, superior quality materials, and precision engineering involved in its construction, offering a strong return on investment for food producers.

Application Scenarios and Industry Impact

The High speed Sausage filler-linker-hanger line finds its primary application in large-scale meat processing facilities, industrial food production plants, and specialized sausage manufacturers. Its versatility allows it to handle a wide range of products and production scales, serving as the backbone for various sausage varieties. Typical application environments include:

- Large-scale Meat Processing Plants: Facilities producing thousands of tons of sausages annually, requiring high throughput and continuous operation. This includes companies supplying supermarkets, foodservice, and export markets.

- Industrial Food Production Plants: Factories that produce ready meals, convenience foods, or ingredients for other food products, where sausages are a key component.

- Specialized Sausage Manufacturers: Companies focusing on specific types of sausages (e.g., organic, gluten-free, ethnic varieties) that require precise control over ingredients and processing to maintain their unique characteristics.

The line's capability extends to processing a diverse range of sausage types:

- Fresh Sausages: Bratwurst, Italian sausage, breakfast sausage, where precise portioning and gentle handling are crucial to maintain product texture and appearance.

- Cooked Sausages: Frankfurters, hot dogs, bologna, which benefit from uniform linking for consistent cooking and smoking processes.

- Smoked Sausages: Kielbasa, andouille, requiring efficient and consistent hanging for optimal smoke absorption and flavor development.

- Specialty Sausages: Ethnic varieties, gourmet sausages, or those with unique casings, where consistent quality, exact portioning, and premium presentation are highly valued.

The impact of implementing a High speed Sausage filler-linker-hanger line is profound, leading to significant operational and financial benefits across the production chain:

- Increased Throughput and Capacity: Dramatically boosts production volume, allowing manufacturers to meet higher market demand and capitalize on growth opportunities. For example, a line capable of 1500 links/minute translates to over 7 million sausages in a single 8-hour shift, an unattainable figure with manual methods.

- Enhanced Product Consistency: Automated portioning and linking ensure uniform size, weight, and appearance of every sausage, leading to higher customer satisfaction, reduced waste, and compliance with strict regulatory standards (e.g., FDA net weight regulations).

- Superior Hygiene and Food Safety: Reduced manual contact, use of food-grade materials (SUS304/316L), and integrated CIP capabilities significantly minimize the risk of contamination, aligning with HACCP and ISO 22000 standards. This reduces the risk of costly product recalls.

- Reduced Labor Costs: Automation significantly lowers the need for manual operators in repetitive, strenuous tasks, redirecting skilled labor to more value-added activities such as quality control, supervision, or product development. This often leads to a quick return on investment.

- Improved Yield and Reduced Waste: Precise filling and linking minimize product loss due to overfilling or casing breakage, improving overall operational yield by 1-3%, which translates to substantial savings on raw materials over time.

- Quick Changeovers: Modern lines are designed for fast and easy changeovers between different product types or casing sizes, maximizing operational flexibility and minimizing downtime between production runs. This is crucial for manufacturers producing a diverse portfolio of products.

The strategic adoption of a High speed Sausage filler-linker-hanger line thus transcends mere equipment upgrade; it transforms a production facility into a highly efficient, quality-driven, and cost-effective operation.

Key Technical Advantages

The technological sophistication of the High speed Sausage filler-linker-hanger line offers distinct advantages that set it apart from conventional or semi-automated systems. These advantages are rooted in advanced engineering and design principles aimed at maximizing performance, reliability, and hygiene:

- Precision Portioning Systems: Utilizing advanced servo-driven filling technology, these lines achieve unparalleled accuracy in portion weight, often with deviations of less than ±0.5 grams. This precision minimizes costly overfilling (product giveaway), ensures consistent product quality batch after batch, and provides significant raw material savings over time. The vacuum system within the filler also eliminates air pockets, resulting in a denser, more uniform sausage texture.

- Advanced Linking Mechanisms: Patented linking systems minimize casing breakage and ensure tight, uniform links, regardless of casing type (natural collagen, cellulose, or fibrous) or diameter. Some systems incorporate advanced cutting mechanisms that are self-sharpening or easily replaceable, reducing maintenance downtime. This ensures a consistent product appearance and allows for better handling in subsequent processing steps.

- Integrated Hanger Automation: The seamless, automated transfer of linked sausages onto smoke sticks or hanging racks is a critical advantage. This eliminates the manual, labor-intensive, and often inconsistent process of hand-hanging. Automation here significantly speeds up the overall process, ensures consistent hanging density for optimal smoking or cooking, and improves hygiene by reducing human contact.

- Robust Construction and Durability: Built with heavy-duty, food-grade stainless steel frames (typically SUS304 or SUS316L) and components, these lines are designed for continuous, multi-shift operation in demanding industrial environments. Their robust construction minimizes vibrations, enhances stability, and ensures long-term reliability and an extended operational lifespan, often exceeding 15-20 years with proper maintenance.

- Intuitive HMI and Recipe Management: User-friendly Human-Machine Interface (HMI) touchscreens, often powered by industry-leading PLCs like Siemens or Allen-Bradley, allow operators to easily manage production parameters, store multiple product recipes, and monitor real-time performance data. This simplifies operation, reduces training time, and enables rapid changeovers between different product types. Advanced diagnostics capabilities also help in proactive maintenance.

- Energy Efficiency: Modern High speed Sausage filler-linker-hanger line systems incorporate energy-saving motors (e.g., IE3/IE4 efficiency classes) and optimized hydraulic or pneumatic systems to reduce power consumption per kilogram of product. This not only lowers operational costs but also contributes to the sustainability goals of the food processing plant.

- Hygienic Design (EHEDG principles): Designed with sloped surfaces, minimal horizontal ledges, open frame structures, and easily accessible components, these lines facilitate thorough cleaning and prevent bacterial growth. Adherence to European Hygienic Engineering & Design Group (EHEDG) guidelines ensures that all food contact surfaces are smooth, non-porous, and easily sanitized, drastically reducing the risk of contamination and supporting strict HACCP protocols.

- Remote Monitoring and IoT Integration: Many high-end models offer connectivity features, allowing for remote monitoring of machine performance, predictive maintenance alerts, and integration with broader Industry 4.0 and smart factory systems. This enables data-driven decision-making and optimizes overall plant efficiency.

These technical advantages collectively position the High speed Sausage filler-linker-hanger line as an indispensable asset for any food producer committed to high-volume, high-quality, and cost-effective sausage production.

Manufacturer Comparison and Choosing the Right Partner

Selecting the right manufacturer for a High speed Sausage filler-linker-hanger line is a critical decision that impacts long-term operational success, product quality, and return on investment. While many companies offer similar machinery, key differentiators can significantly influence the overall value proposition. It’s imperative to look beyond the initial purchase price and consider factors such as technological advancement, build quality, after-sales support, and the manufacturer's overall industry reputation.

- Technological Innovation: Leading manufacturers continuously invest heavily in Research & Development, offering cutting-edge features like advanced sensor technology for real-time defect detection, sophisticated predictive maintenance capabilities leveraging AI, and seamless integration with broader Industry 4.0 systems and factory automation networks.

- Build Quality and Material Standards: Verify the quality of stainless steel used (e.g., specific grades like SUS304 vs. SUS316L for all food contact parts), the precision of machining (e.g., CNC tolerance levels), and the quality of welding (e.g., sanitary welds, minimal crevices). Look for certifications like CE, USDA, or FDA compliance for food contact materials, which are non-negotiable for food processing equipment.

- After-Sales Service and Support: A robust service network, readily available genuine spare parts, remote diagnostics capabilities, and responsive technical support are paramount for minimizing costly downtime. Inquire about extended warranty periods, comprehensive service contracts, and thorough training programs for your operational and maintenance staff. A manufacturer's commitment to post-sales support is a strong indicator of their long-term reliability.

- Customization Capabilities: Can the manufacturer truly tailor the line to your specific production needs, considering unique plant layouts, space constraints, or particular product requirements (e.g., unique casing types, special sausage recipes)? A flexible manufacturer can integrate their line seamlessly into your existing infrastructure.

- Reputation and Experience: Longevity in the industry, verifiable client testimonials, case studies, and a portfolio of successful installations globally speak volumes about a manufacturer's reliability, expertise, and understanding of industry challenges and solutions. Companies with decades of specialized experience, like Bossin Machinery, often have a deeper understanding of the nuances of sausage production.

- Total Cost of Ownership (TCO): Consider not just the initial capital expenditure, but also running costs (energy consumption, labor), maintenance costs (spare parts, service contracts), and potential downtime costs. A higher-quality machine with better efficiency and reliability often has a lower TCO over its lifespan.

This comparison table provides a generalized overview of how a specialized manufacturer like Bossin Machinery might differentiate its High speed Sausage filler-linker-hanger line offerings:

| Feature | Manufacturer A (General) | Bossin Machinery (Example) | Manufacturer C (Budget) |

|---|---|---|---|

| Material Quality (Food Contact) | Mostly SUS304 | Premium SUS304/SUS316L for all contact parts, polished to high Ra value | Mixed grade / Less specified, potentially lower Ra |

| Control System | Basic PLC (e.g., local brand), limited HMI | Industry-leading Siemens/Allen-Bradley PLC, advanced HMI Touchscreen with recipe management & diagnostics | Proprietary, often limited features and support |

| Linking Speed (links/min) | 800-1000 | Consistently up to 1500+, with options for even higher speeds | 500-800, may vary significantly |

| Portioning Accuracy (g) | ±2.0 | Exceptional ±0.5 - ±1.5 (servo-driven precision) | ±3.0+ (mechanical or basic hydraulic) |

| After-Sales Support | Standard phone/email, regional service only | Global service network, 24/7 remote diagnostics, rapid spare parts delivery, dedicated on-site training & support plans | Limited, often outsourced or delayed |

| Certifications & Compliance | Basic CE | Full CE, USDA, FDA (material compliance), ISO 9001 (manufacturing), HACCP/ISO 22000 compatible design | May lack comprehensive international certifications |

| Customization Options | Limited, standard models only | Extensive, including layout adaptations, specific product tooling, integration with MES/SCADA, environmental adaptations | Minimal to non-existent |

| Warranty Period | 12 Months | 12-24 Months (comprehensive, component-specific) | 6-12 Months (often limited scope) |

This comparison highlights that while entry-level machines might seem cost-effective initially, the long-term benefits in terms of reliability, performance, efficiency, and comprehensive support offered by specialized manufacturers like Bossin Machinery for their High speed Sausage filler-linker-hanger line often yield a much higher return on investment and significantly lower total cost of ownership over the machine's lifespan. Investing in quality mitigates risks and ensures consistent, high-volume production.

Customization Solutions: Tailoring to Your Needs

Every sausage production facility has unique requirements, from space limitations and existing infrastructure to specific product portfolios and desired levels of automation. A reputable manufacturer of High speed Sausage filler-linker-hanger line systems understands this diversity and offers extensive customization options to ensure seamless integration and optimal performance. This bespoke approach differentiates top-tier suppliers from mass-producers.

Key areas for customization include:

- Line Layout Adaptation: Designing the physical configuration of the line to perfectly fit existing plant layouts, including straight-line, L-shaped, U-shaped, or even multi-level arrangements. This ensures efficient material flow and maximizes available floor space. Manufacturers can provide detailed CAD layouts and 3D renderings to visualize the integration.

- Casing Handling Systems: Specialized solutions for challenging or delicate casing types (e.g., very thin natural casings, specific collagen films). This can include automated casing loading systems, gentle tensioning devices, or specialized feeding mechanisms for increased efficiency and reduced breakage.

- Product-Specific Tooling: Custom nozzles, linking mechanisms, or hanging solutions specifically optimized for unique sausage types, diameters, lengths, or filling consistencies. This ensures optimal performance for specialized products, whether it's a gourmet bratwurst or a slender breakfast sausage, maintaining critical dimensions and appearance.

- Integration with Existing Systems: Providing necessary hardware and software interfaces for seamless data exchange and control integration with existing plant MES (Manufacturing Execution Systems), SCADA (Supervisory Control and Data Acquisition) systems, or ERP (Enterprise Resource Planning) software. This enables centralized monitoring, data analysis, and overall production optimization.

- Environmental Adaptations: Customizations to ensure sustained performance in extreme temperature environments (e.g., very cold processing rooms, high-humidity zones) or areas with specific atmospheric conditions. This might involve specialized electrical enclosures or corrosion-resistant coatings.

- Specialized Cleaning Features: Enhanced CIP options, additional access points for manual cleaning, or specialized spray nozzles for particularly stringent hygienic environments, often required for allergen control or sensitive products. Some lines can be designed for full wash-down capability.

- Downstream Equipment Integration: Designing the hanging unit to seamlessly interface with automated smokehouses, chilling tunnels, or direct packaging lines. This eliminates manual transfers and enhances end-to-end automation.

- Safety Enhancements: Incorporating additional safety features beyond standard requirements, such as enhanced interlocks, specialized guarding, or integrated emergency stop systems tailored to specific plant safety protocols.

Collaborating closely with a manufacturer capable of providing these tailored solutions ensures that the High speed Sausage filler-linker-hanger line integrates perfectly into your existing operations, maximizes efficiency, and minimizes unforeseen challenges or costly retrofits down the line. This partnership approach leads to a solution that truly addresses a client's specific production goals and constraints.

Real-World Application Cases and Client Success Stories

The impact and transformative potential of the High speed Sausage filler-linker-hanger line are best illustrated through real-world application cases where businesses have achieved significant operational improvements and financial gains. These success stories underscore the tangible return on investment that advanced automation can deliver.

Case Study 1: Major European Sausage Producer (Frankfurters)

A prominent European sausage producer, operating multiple large facilities, faced challenges with inconsistent product weight and high labor costs on their high-volume frankfurter line. Their semi-automated setup led to variations in portioning, resulting in significant "giveaway" (overfilling) and increased raw material expenses. Manual linking and hanging also introduced hygiene risks and limited throughput scalability.

After a comprehensive evaluation, they installed a state-of-the-art High speed Sausage filler-linker-hanger line from a leading supplier, configured for continuous 24/7 operation. The new line featured servo-driven vacuum filling for precise portion control and an automated hanging system. Within the first six months of operation, they reported a 30% increase in production throughput, allowing them to meet rising market demand without expanding floor space. Crucially, they achieved a remarkable 15% reduction in product giveaway due to the improved portioning accuracy, which translated into hundreds of thousands of Euros in raw material savings annually. Furthermore, they realized a 20% reduction in labor costs for that specific line, reallocating staff to other critical areas of their growing business. The consistent product quality also led to positive customer feedback and fewer quality control issues.

Case Study 2: North American Artisanal Sausage Company (Gourmet Bratwurst)

A rapidly growing artisanal sausage company in North America, renowned for its gourmet bratwursts, needed to scale production significantly while maintaining its commitment to premium quality and consistent appearance. Their previous batch-based, semi-automated process led to undesirable variations in linking, inconsistent sausage lengths, and a significant bottleneck in the hanging stage, limiting their expansion capabilities.

The company invested in a customized High speed Sausage filler-linker-hanger line that included specialized tooling for their specific casing type and a flexible control system for diverse recipes. The manufacturer provided extensive training to their team. The implementation allowed them to increase their output by over 50% in the first year alone, enabling them to expand into new retail channels. The consistent appearance, precise linking, and uniform portioning provided by the automated line significantly enhanced their brand's appeal and market competitiveness. The reduced manual handling also improved overall food safety and reduced product damage, reinforcing their brand's reputation for quality.

Case Study 3: Asian Food Service Supplier (Pre-cooked Cocktail Sausages)

An Asian food service supplier specializing in pre-cooked cocktail sausages for hotels and restaurants faced immense pressure to reduce per-unit costs and increase volume. Their older machines frequently broke casings and had high maintenance requirements.

By upgrading to a robust High speed Sausage filler-linker-hanger line known for its durability and gentle casing handling, they not only boosted their production capacity by over 40% but also reduced casing breakage by over 10%, leading to substantial savings on raw material waste. The line's integrated CIP system also streamlined their sanitation process, reducing cleaning time by 25% and enhancing their food safety compliance, which was critical for their institutional clients. The reliability of the new line significantly reduced unplanned downtime, ensuring consistent supply to their demanding clientele.

These examples demonstrate the tangible benefits of investing in advanced automation through a High speed Sausage filler-linker-hanger line, illustrating improvements in throughput, cost efficiency, product quality, and overall operational reliability across diverse food processing environments.

Ensuring Quality and Trust: Standards, Warranty & Support

Establishing trust in a manufacturer and its product, particularly for high-value and mission-critical equipment like the High speed Sausage filler-linker-hanger line, is built on several interconnected pillars: adherence to industry standards, transparent warranty policies, and robust after-sales support. These elements collectively assure a client of the product's reliability, safety, and the manufacturer's long-term commitment.

- Industry Certifications and Compliance: Reputable manufacturers of food processing equipment adhere to and often exceed international standards. Key certifications and compliance considerations include:

- CE Marking: Mandatory for equipment sold within the European Economic Area, ensuring compliance with essential health, safety, and environmental protection requirements. This is a fundamental safety baseline.

- USDA/FDA Compliance: Critical for equipment used in North American food processing, ensuring that materials (e.g., food-grade stainless steel) and design meet stringent hygiene, cleanability, and safety regulations. Compliance often involves specific surface finishes, accessible components for cleaning, and absence of harborage points for bacteria.

- HACCP & ISO 22000 Compatibility: While not machine certifications per se, the machine's hygienic design, ease of cleaning (e.g., CIP capabilities), and operational parameters should inherently support a facility's Hazard Analysis and Critical Control Points (HACCP) plan and its ISO 22000 (Food Safety Management System) certification. This demonstrates the manufacturer's understanding of food safety criticalities.

- ISO 9001: This certification pertains to the manufacturer's quality management system, ensuring consistent product quality, continuous improvement, and customer satisfaction throughout the design, manufacturing, and service processes.

- EHEDG (European Hygienic Engineering & Design Group) Principles: Adherence to EHEDG guidelines ensures the machine is designed for optimal hygiene and ease of cleaning, minimizing microbial contamination risks.

- Warranty and Lifespan: A standard warranty for a new High speed Sausage filler-linker-hanger line is typically 12 to 24 months, covering manufacturing defects and ensuring functional reliability from commissioning. Beyond the warranty, the expected operational lifespan for a well-designed and properly maintained machine, built with quality materials and precision engineering, is a substantial 15-20 years. This long lifespan signifies a durable asset that provides decades of consistent production and a strong return on investment.

- After-Sales Support: Critical for operational continuity and maximizing the uptime of the High speed Sausage filler-linker-hanger line. Comprehensive support includes:

- Spare Parts Availability: Ensuring quick and reliable access to genuine spare parts is paramount. Reputable manufacturers maintain extensive spare parts inventories and efficient logistics channels to minimize downtime during repairs.

- Technical Assistance: Providing round-the-clock technical support via phone, email, and often remote diagnostics capabilities, allowing experts to troubleshoot issues from afar and guide local technicians.

- On-site Service: Availability of highly skilled and certified technicians for installation, commissioning, preventative maintenance, complex repairs, and troubleshooting at the client's facility.

- Training Programs: Comprehensive training for the client's operational staff (for efficient use and recipe management) and maintenance personnel (for routine upkeep and minor repairs) to ensure proficient use and longevity of the High speed Sausage filler-linker-hanger line. Many manufacturers offer recurring training or refresher courses.

- Maintenance Contracts: Offering structured maintenance contracts that include regular inspections, preventative maintenance, and priority service to proactively address potential issues and extend the machine's life.

- Client Testimonials and References: Genuine feedback, case studies, and direct references from existing clients provide invaluable insight into a manufacturer's reliability, product performance, and the quality of their service support. A transparent manufacturer will readily provide such references.

By prioritizing these factors, businesses can confidently invest in a High speed Sausage filler-linker-hanger line that not only meets their immediate production demands but also adheres to the highest standards of safety, quality, and reliability, ensuring long-term operational success and peace of mind.

Frequently Asked Questions (FAQ)

Here are some common questions regarding the High speed Sausage filler-linker-hanger line, providing deeper insights into its operation, maintenance, and benefits:

- Q1: What is portioning accuracy, and why is it important for a High speed Sausage filler-linker-hanger line?

- A1: Portioning accuracy refers to the consistency of the weight of each individual sausage produced. It's typically measured in grams (e.g., ±0.5g). It's crucial because it directly impacts profitability by minimizing "giveaway" (overfilling beyond the declared weight on packaging), ensures product uniformity for consumer satisfaction, and optimizes raw material usage. High precision is achieved through advanced servo-driven filling systems that precisely control the meat emulsion flow and cut-off points.

- Q2: What types of casings can a High speed Sausage filler-linker-hanger line handle, and are there limitations?

- A2: Modern High speed Sausage filler-linker-hanger line machines are highly versatile and can handle a wide range of casing types, including natural casings (hog, sheep, beef), and various artificial casings like collagen, cellulose, and fibrous casings. Limitations primarily relate to the casing diameter range (e.g., 13 mm to 50 mm is common) and sometimes specific delicate casing properties. Manufacturers typically offer different linking heads or nozzles designed for specific casing types to ensure optimal performance and minimize breakage.

- Q3: How does the cleaning-in-place (CIP) system work on these lines, and what are its benefits for food safety?

- A3: A CIP system allows for automated cleaning and sanitization of the machine's internal parts, particularly the filler and manifold, without extensive disassembly. It works by circulating pre-programmed sequences of cleaning solutions (e.g., hot water, detergents, sanitizers) through the system. The benefits are significant for food safety: it ensures thorough, consistent cleaning; reduces reliance on manual labor, minimizing human error; shortens cleaning cycles, increasing uptime; and significantly reduces the risk of cross-contamination and bacterial growth, aligning with HACCP and ISO 22000 food safety standards.

- Q4: What are the typical installation standards and facility requirements for a High speed Sausage filler-linker-hanger line?

- A4: Installation usually requires a level, reinforced concrete floor capable of supporting the machine's significant weight and vibration. Adequate space for operation, maintenance access (e.g., for cleaning and part replacement), and product flow is essential. Key utility connections include a robust three-phase electrical supply (e.g., 400V/50Hz or 480V/60Hz), clean compressed air (typically 0.6-0.8 MPa) for pneumatic components, and access to potable water and drainage for cleaning purposes. Manufacturers provide detailed pre-installation guides and often offer on-site installation and commissioning services to ensure proper setup.

- Q5: What level of maintenance is required for a High speed Sausage filler-linker-hanger line, and how often?

- A5: Regular maintenance is crucial for the longevity and optimal performance of a High speed Sausage filler-linker-hanger line. This includes daily cleaning (via CIP and external wash-down), routine lubrication of moving parts, periodic inspection and replacement of wear parts (e.g., seals, O-rings, cutting blades, valve components), checking hydraulic/pneumatic fluid levels and filters, and calibration verification. Manufacturers provide detailed preventative maintenance schedules (e.g., weekly, monthly, quarterly, annually) and recommend using genuine spare parts. Increasingly, machines incorporate predictive maintenance features that alert operators to potential issues before they cause downtime.

- Q6: Can a High speed Sausage filler-linker-hanger line be integrated into an existing production line or smart factory system?

- A6: Yes, most modern High speed Sausage filler-linker-hanger line systems are designed with modularity and connectivity in mind. They can be seamlessly integrated into existing or new production lines, connecting with upstream equipment (e.g., meat grinders, mixers, emulsifiers) and downstream processes (e.g., smokehouses, chilling tunnels, packaging machines) via conveyors, sensors, and synchronized control systems. Many high-end models support communication protocols for integration with plant-wide Manufacturing Execution Systems (MES) or SCADA (Supervisory Control and Data Acquisition) systems, enabling centralized monitoring, data analysis, and overall smart factory operations.

- Q7: What is the typical lead time for manufacturing and delivery, and what about global installation?

- A7: The lead time for manufacturing and delivery of a High speed Sausage filler-linker-hanger line can vary significantly based on customization requirements, machine complexity, and the manufacturer's production schedule. Generally, it ranges from 12 to 24 weeks from order confirmation. The delivery process usually involves robust crating for secure international shipping, comprehensive documentation (manuals, electrical diagrams), and often includes pre-scheduled installation, commissioning, and initial operator training upon arrival at the client's facility, whether locally or globally. Reputable manufacturers have experience with international logistics and on-site support teams worldwide.

Conclusion: Investing in the Future of Sausage Production

The High speed Sausage filler-linker-hanger line represents a critical, strategic investment for any serious player in the meat processing industry aiming for unparalleled efficiency, consistent product quality, and sustained profitability. By seamlessly automating the core processes of filling, linking, and hanging, these advanced machines enable manufacturers to meet surging consumer demand, uphold the most stringent standards of food safety and hygiene, and significantly reduce operational costs through optimized labor and material usage. The benefits extend far beyond mere production volume, encompassing superior product aesthetics and consistency, reduced dependence on manual labor, and enhanced hygienic practices that safeguard brand reputation and consumer health.

Choosing a reputable manufacturer, like Bossin Machinery, with a proven track record, an unwavering commitment to technological innovation, and comprehensive after-sales support, ensures a long-term partnership that drives sustainable growth and secures a competitive advantage in the dynamic global food market. Embracing this cutting-edge technology is not just about upgrading equipment; it's about future-proofing your production capabilities, ensuring compliance with evolving standards, and cementing your position as a leader in high-quality, efficient sausage manufacturing. In an industry where precision, speed, and hygiene are paramount, the High speed Sausage filler-linker-hanger line is an indispensable asset for success.

References and Further Reading:

- Food Processing Technology Journal: Sausage Processing Equipment Innovations – Insights into modern trends and technological advancements in the field of meat processing equipment.

- Meat & Poultry Magazine: Automation in Meat Processing Gains Momentum – An industry perspective on the growing adoption of automation to address labor challenges and efficiency demands.

- ResearchGate Publication: Automation in Food Industry: Trends and Challenges (May 2020) – Academic insight into the broader landscape of automation in the food sector.

- USDA Food Safety and Inspection Service (FSIS) Guidelines: FSIS Compliance Guidelines – Official government guidelines on food safety for meat and poultry products in the U.S.

Latest news

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Automated Clipping&Pneumatic Sausage Filling

NewsAug.09,2025

-

Pneumatic Clipping Machine-SHJZ Bossin Machinery|Precision Efficiency&Automated Clipping

NewsAug.09,2025

-

High-Speed Sausage Filler-Linker-Hanger Line | Automated Efficiency

NewsAug.09,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Efficiency

NewsAug.09,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Meat Processing

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Sausage Production Line, Precision Clipping

NewsAug.08,2025