Shk . 18, 2025 06:07 Back to list

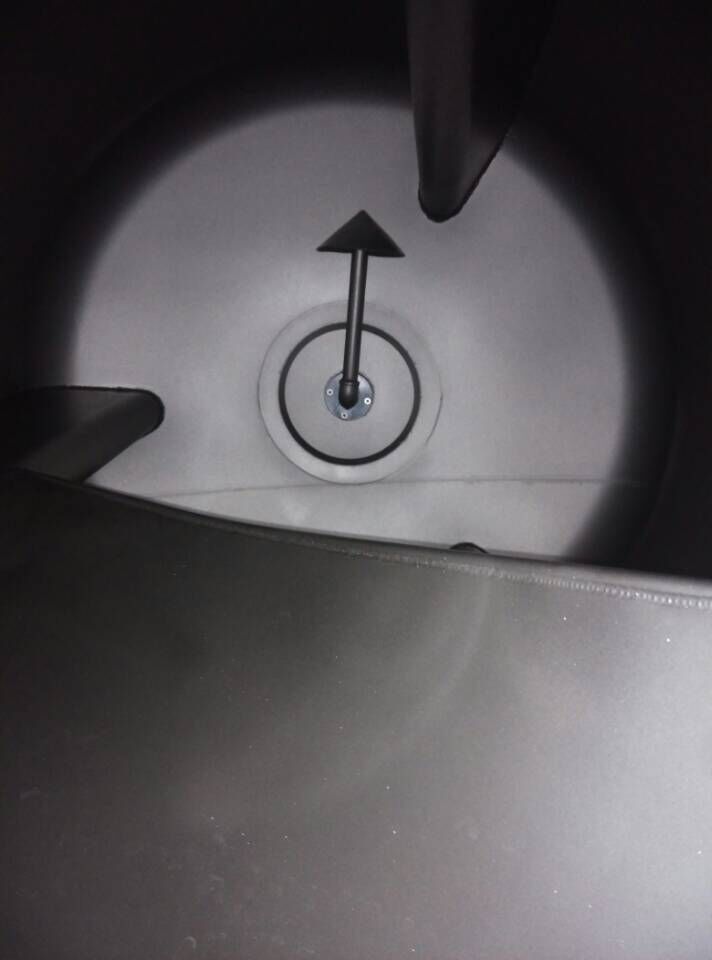

wholesale pneumatic double clipper

Navigating the realm of wholesale pneumatic double clippers offers an exhilarating avenue filled with innovative packaging solutions tailored to diverse industries. As businesses strive to bolster their operational efficiency, it is imperative to delve into this sophisticated packaging tool that marries precision with robustness.

The authoritativeness of pneumatic double clippers is underscored by their widespread adoption across major global players in sectors such as meat processing, dairy products, and even pet food manufacturing. Industry leaders extol the reliability and precision of these machines, often citing them as indispensable in maintaining high quality and safety standards. Furthermore, manufacturers of these machines consistently meet international safety and quality certifications, reinforcing their standing as a trusted tool in packaging solutions. Trustworthiness in pneumatic double clippers is further bolstered by the longevity and durability they provide. Constructed from high-grade materials engineered to resist wear and tear, these machines boast a reduced frequency of maintenance and downtime. This aspect not only instills confidence in businesses regarding operational continuity but also contributes to a reduction in long-term operational costs. Testimonials from industry experts and existing users converge on the viewpoint that the investment in pneumatic double clippers is one marked by visible return on investment through enhanced productivity, reduced wastage, and improved packaging consistency. Businesses are increasingly turning to these machines to gain a competitive edge, optimize resource utilization, and elevate their operational standards to meet and exceed industry benchmarks. In conclusion, exploring wholesale pneumatic double clippers translates into an opportunity to harness cutting-edge technology that champions efficiency and reliability. As a centerpiece in modern packaging solutions, their ability to transform and streamline packaging processes continues to set new standards, securing their place as a pivotal investment for any business committed to excellence and growth. The union of innovative engineering and practical application in these clippers redefines what it means to achieve operational excellence in today's competitive market landscape.

The authoritativeness of pneumatic double clippers is underscored by their widespread adoption across major global players in sectors such as meat processing, dairy products, and even pet food manufacturing. Industry leaders extol the reliability and precision of these machines, often citing them as indispensable in maintaining high quality and safety standards. Furthermore, manufacturers of these machines consistently meet international safety and quality certifications, reinforcing their standing as a trusted tool in packaging solutions. Trustworthiness in pneumatic double clippers is further bolstered by the longevity and durability they provide. Constructed from high-grade materials engineered to resist wear and tear, these machines boast a reduced frequency of maintenance and downtime. This aspect not only instills confidence in businesses regarding operational continuity but also contributes to a reduction in long-term operational costs. Testimonials from industry experts and existing users converge on the viewpoint that the investment in pneumatic double clippers is one marked by visible return on investment through enhanced productivity, reduced wastage, and improved packaging consistency. Businesses are increasingly turning to these machines to gain a competitive edge, optimize resource utilization, and elevate their operational standards to meet and exceed industry benchmarks. In conclusion, exploring wholesale pneumatic double clippers translates into an opportunity to harness cutting-edge technology that champions efficiency and reliability. As a centerpiece in modern packaging solutions, their ability to transform and streamline packaging processes continues to set new standards, securing their place as a pivotal investment for any business committed to excellence and growth. The union of innovative engineering and practical application in these clippers redefines what it means to achieve operational excellence in today's competitive market landscape.

Next:

Latest news

-

Sausage Link Cutter JC999-03 | Fast & Precise Sausage Slicing Tool

NewsAug.03,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, High Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, Efficient Meat Processing

NewsAug.03,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine-SHJZ Bossin Machinery | High Efficiency&Flexible Operation

NewsAug.02,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Precision, High Efficiency

NewsAug.02,2025